Iron based alloy powder for spraying

Produktcharakter:

Iron based self melting alloy powder is more widely used than cobalt based and nickel based self melting alloy powders, which have certain wear resistance and heat resistance. Although the spray welding and self melting properties are not as good as cobalt based and nickel based spray welding alloys, and the operation is also difficult to master, the low price of the powder is its main advantage.

| Markenname | Jinchun |

| Herkunft | China |

| Name des Produkts | Iron based alloy powder |

| Anmeldung | Spraying, Laser, etc. |

| Form | Pulver |

| Farbe | Metal gray |

| Größe | 150-300 mesh, etc. |

| Standard | GB/T 19001-2016/ISO9001: 2015 |

| Reinheit | Fe: Bal |

| Material | Iron, and other metals. |

| Verpacken | Stahlfässer |

PRODUKT DETAIL

PRODUKT DETAIL

Produkt Charakter

Iron based self melting alloy powder is more widely used than cobalt based and nickel based self melting alloy powders, which have certain wear resistance and heat resistance. Although the spray welding and self melting properties are not as good as cobalt based and nickel based spray welding alloys, and the operation is also difficult to master, the low price of the powder is its main advantage.

2.Spezifikation

Iron based alloy powder for spraying

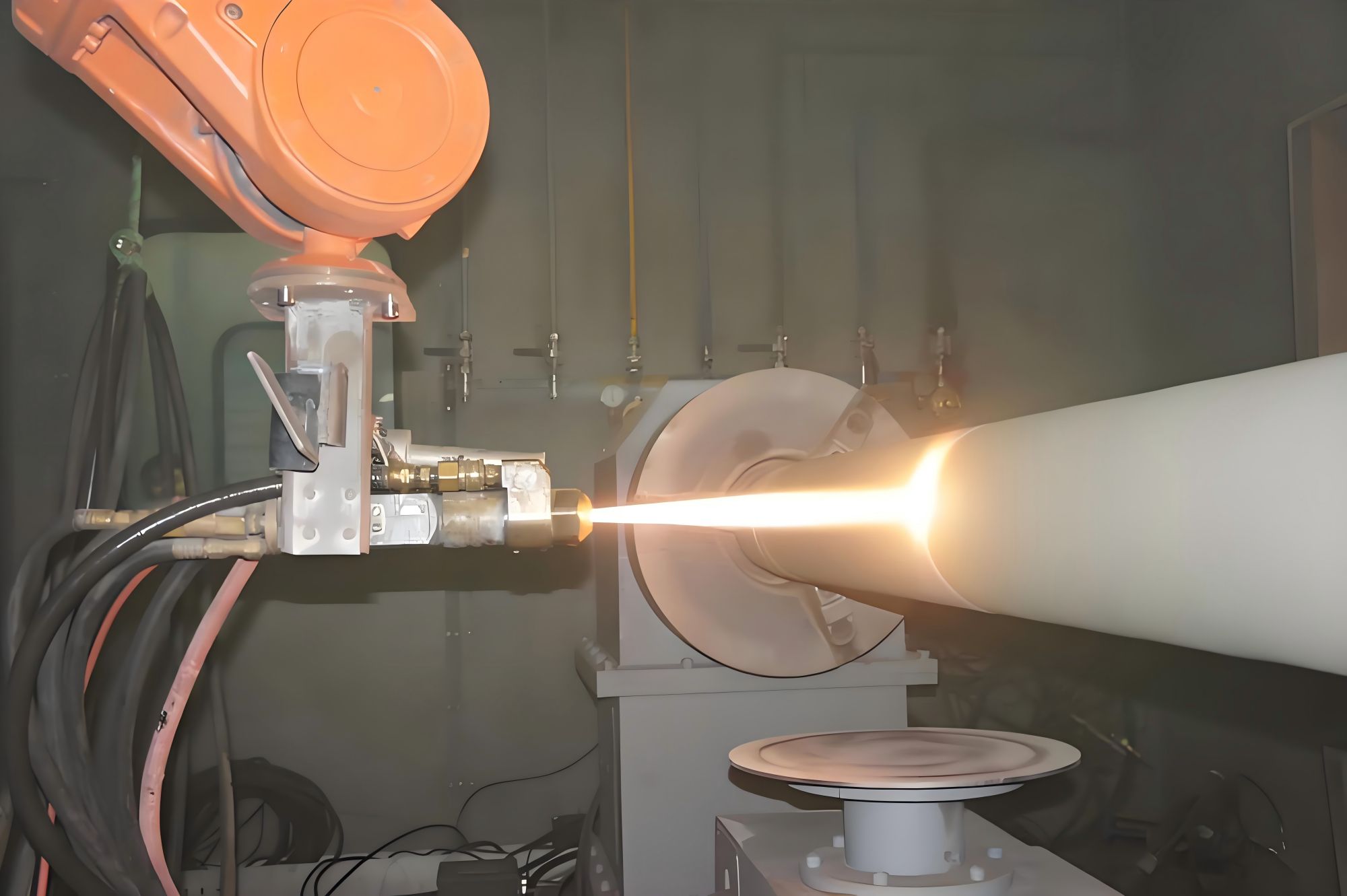

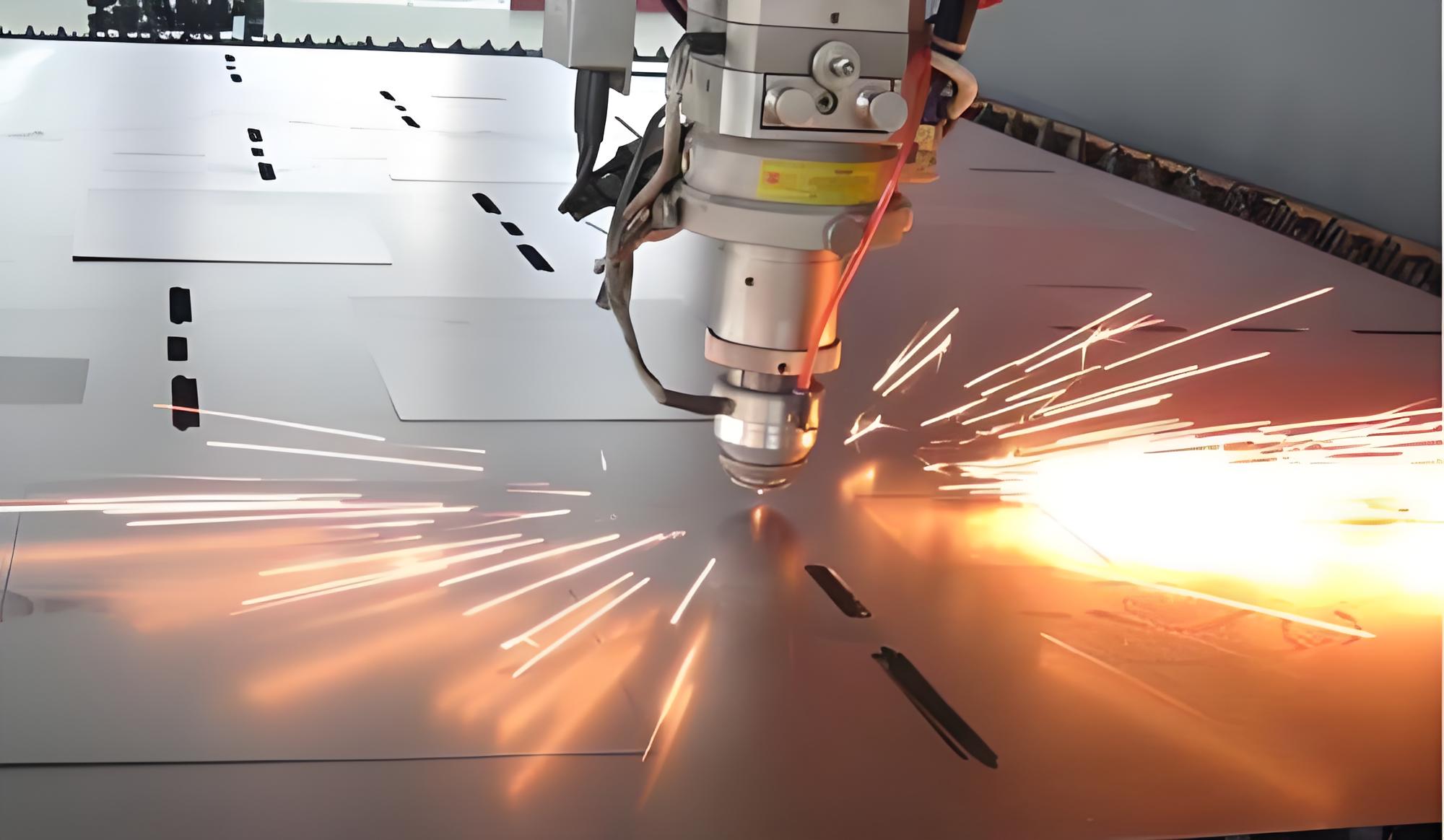

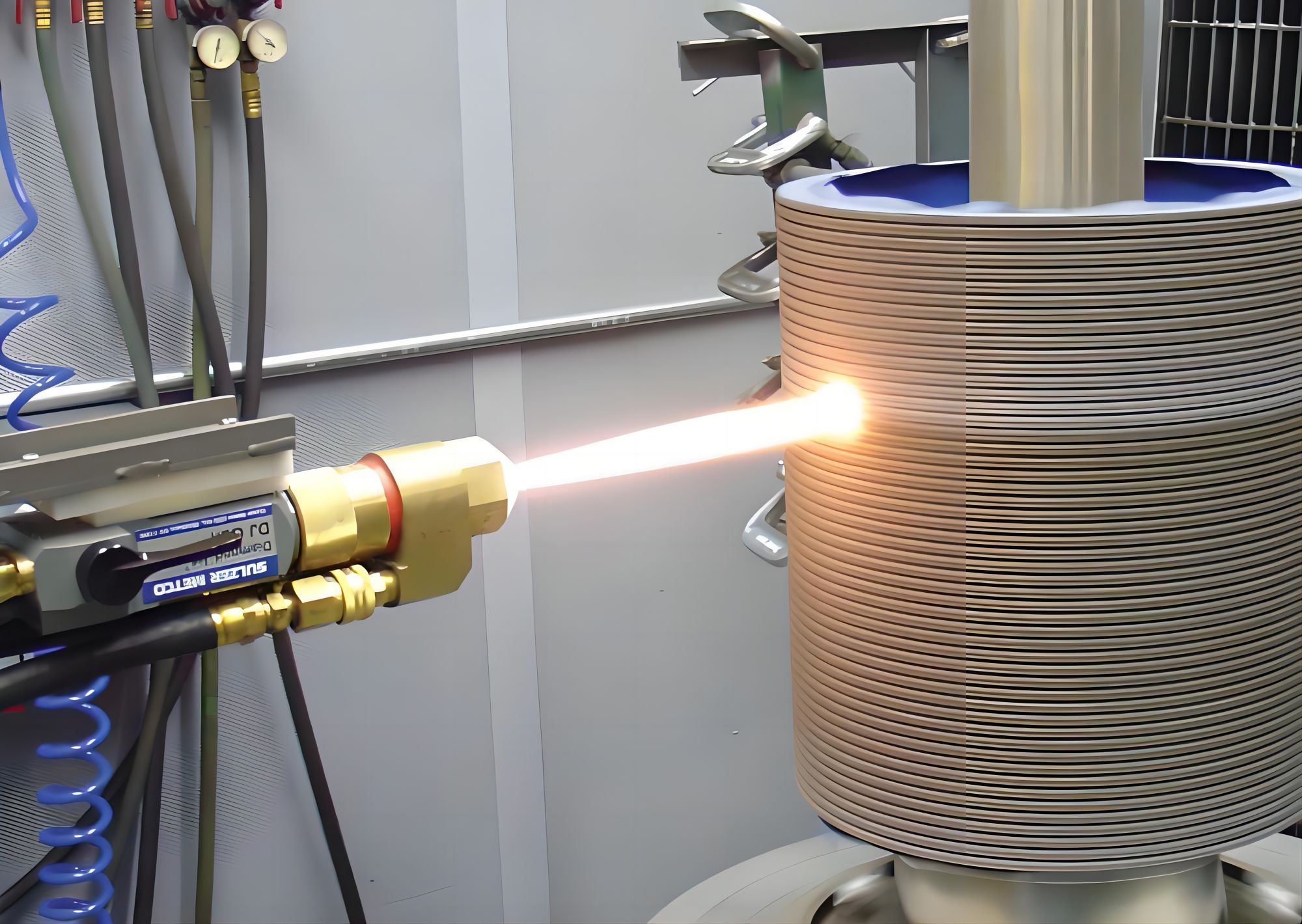

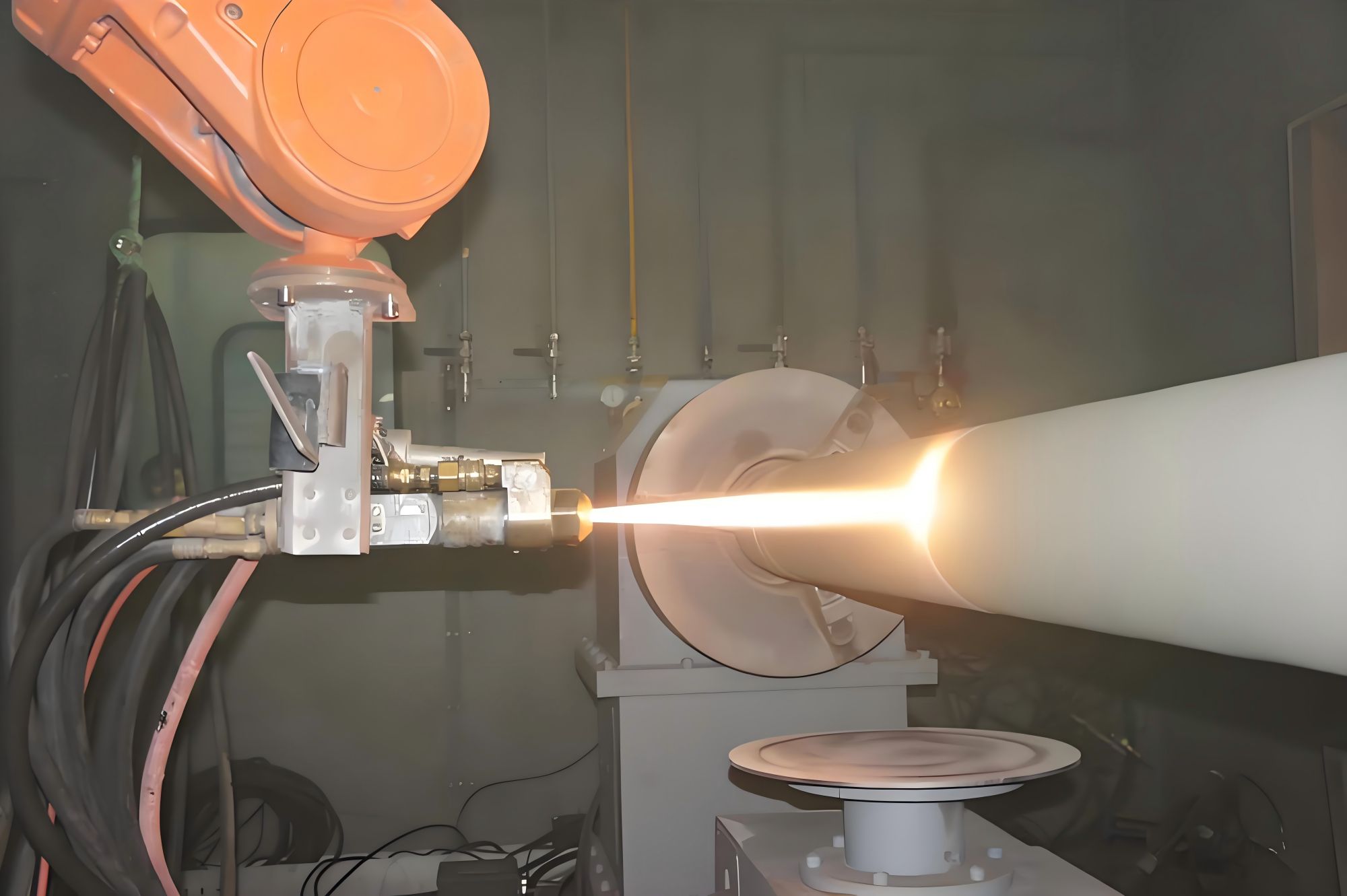

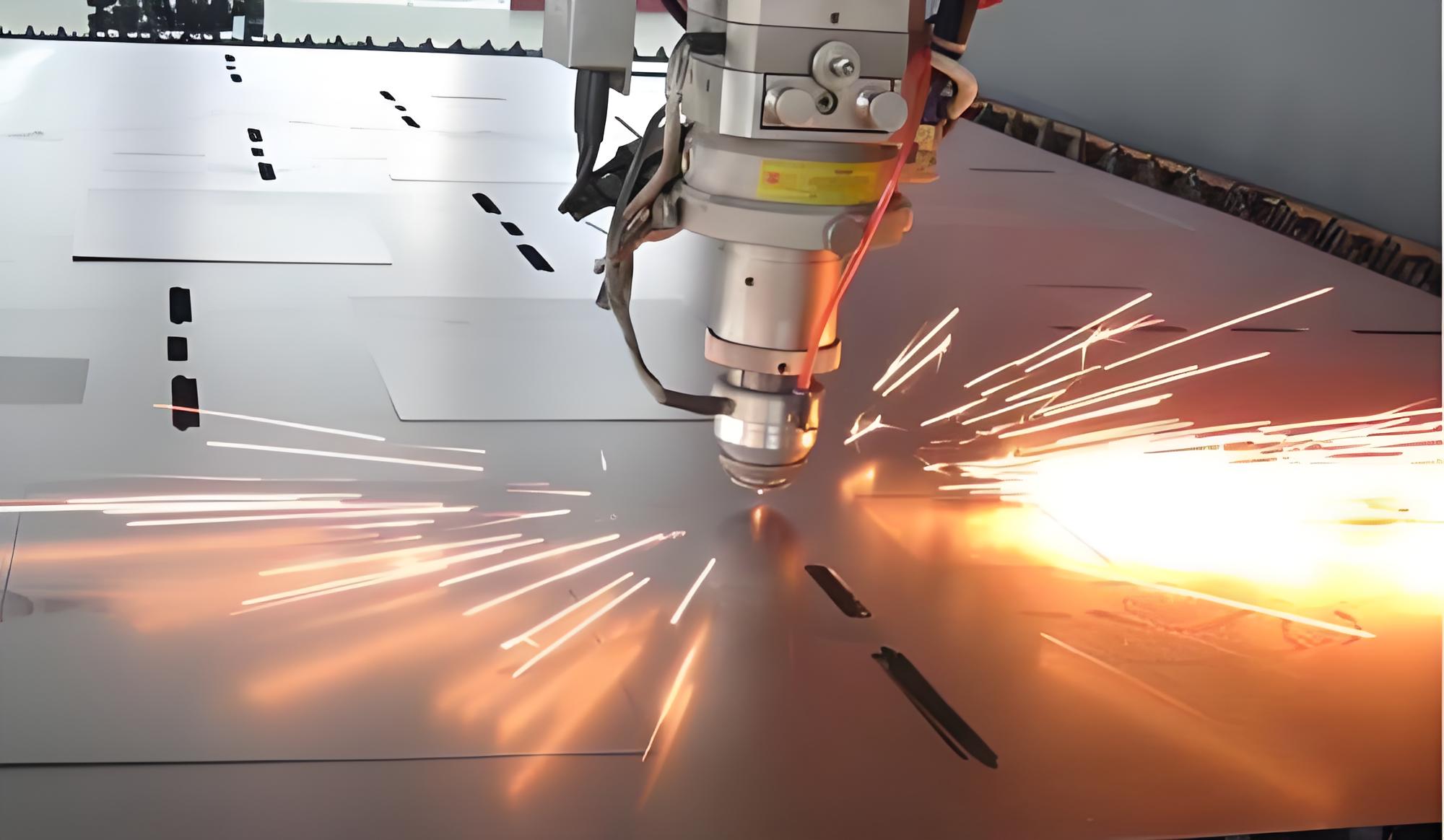

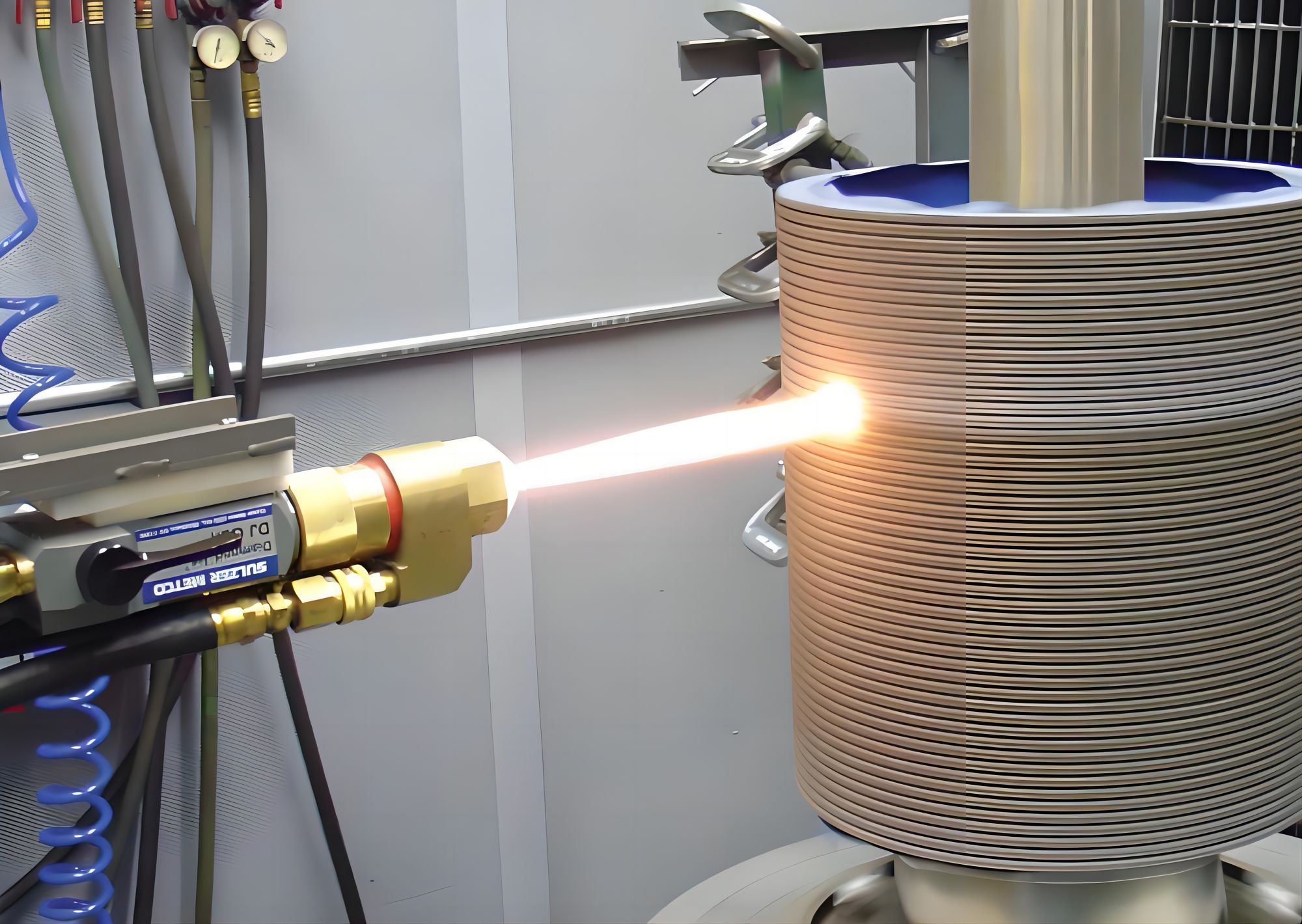

3.Bilder von Rohstoffen und Produktion

Bilder der Produktion:

4.Anwendung

4.Anwendung

| Nein. | Typ | Hardness | Chemical Components (%) | Applications | Spraying Method |

| 1 | T-Fe30 | 30 | C:0.2, Si: 3.0, B: 1.5, Cr: 6, Ni: 28, Fe: Bal. | Excellent fatigue resistance, suitable for applications with low hardness that can withstand repeated impacts | HVOF, Flame, Plasma spraying; Laser |

| 2 | T-Fe45 | 45 | C:0.6, Si: 3.0, B: 2.0, Cr: 12, Ni: 20, Fe: Bal. | Used for repairing easily worn parts of valves, sealing surfaces, and machinery | |

| 3 | T-Fe55 | 55 | C:0.2, Si: 3.0, B: 1.5, Cr: 6, Ni: 28, Fe: Bal. | Repair rake blades, hoe teeth, oil drill pipe joints, scraper shaft | |

| 4 | T-Fe60 | 60 | C:1.2, Si: 3.0, B: 2.0, Cr: 22, Ni: 15, Fe: Bal. | ||

| 5 | T-Fe55T | 55 | C:0.8, Si: 2.0, B: 1.5, Cr: 14, Ni: 16, Fe: Bal. | It has both anti-wear and crack resistance properties, low friction coefficient, and is specifically designed for spray welding of wear-resistant strips on petroleum drill pipes | Plasma spraying; Laser |

4.Anwendung

4.Anwendung

HVOF, Flame, Plasma spraying; Laser

_6258副本-2.jpg)