Sphärische Metallpulver GH3230 Hochtemperaturlegierungspulver

Produktcharakter:

GH3230 is a solid solution strengthened high-temperature alloy with W and Mo as the main strengthening elements. GH3230 alloy mainly improves its oxidation resistance by adding Cr element to the alloy, while adding trace elements to assist in improving the alloy’s oxidation resistance. Therefore, the alloy has good strength, thermal stability, and oxidation resistance. GH3230 alloy can be used to manufacture combustion chambers, flame tubes, heat exchangers, and other components of aviation turbine engines. It can also be used to manufacture combustion chamber components of ground gas turbines and high-temperature equipment components such as thermocouple protective sleeves and flame baffles for industrial furnaces.

| Markenname | Jinchun |

| Herkunft | China |

| Name des Produkts | GH3230 powder |

| Anmeldung | Thermocouple protective sleeves and flame baffles, etc. |

| Form | Pulver |

| Farbe | Metal balck |

| Größe | 15~53μm |

| Standard | GB/T 19001-2016/ISO9001: 2015 |

| Reinheit | Ni: Bal%, Cr:20-24%, W:13-15%, Mo: 1-3%. |

| Material | Ni, Cr, W, Mo |

| Verpacken | Vakuumverpackung |

PRODUKT DETAIL

PRODUKT DETAIL

Produkt Charakter

GH3230 is a solid solution strengthened high-temperature alloy with W and Mo as the main strengthening elements. GH3230 alloy mainly improves its oxidation resistance by adding Cr element to the alloy, while adding trace elements to assist in improving the alloy’s oxidation resistance. Therefore, the alloy has good strength, thermal stability, and oxidation resistance. GH3230 alloy can be used to manufacture combustion chambers, flame tubes, heat exchangers, and other components of aviation turbine engines. It can also be used to manufacture combustion chamber components of ground gas turbines and high-temperature equipment components such as thermocouple protective sleeves and flame baffles for industrial furnaces.

2.Spezifikation

GH3230 powder

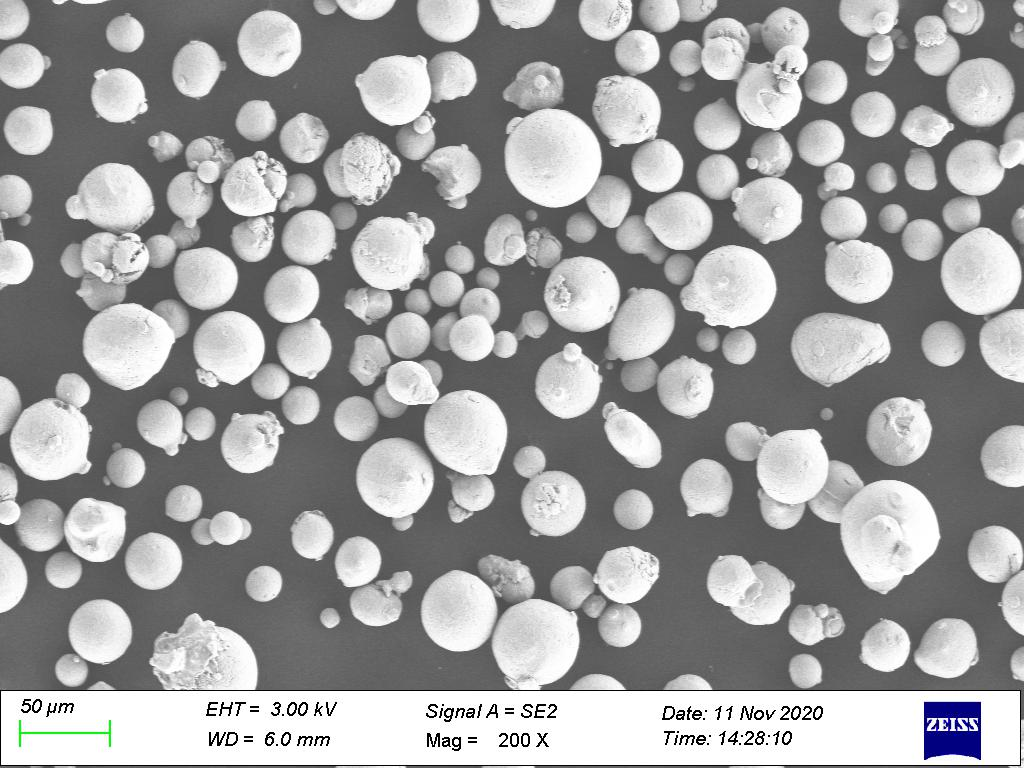

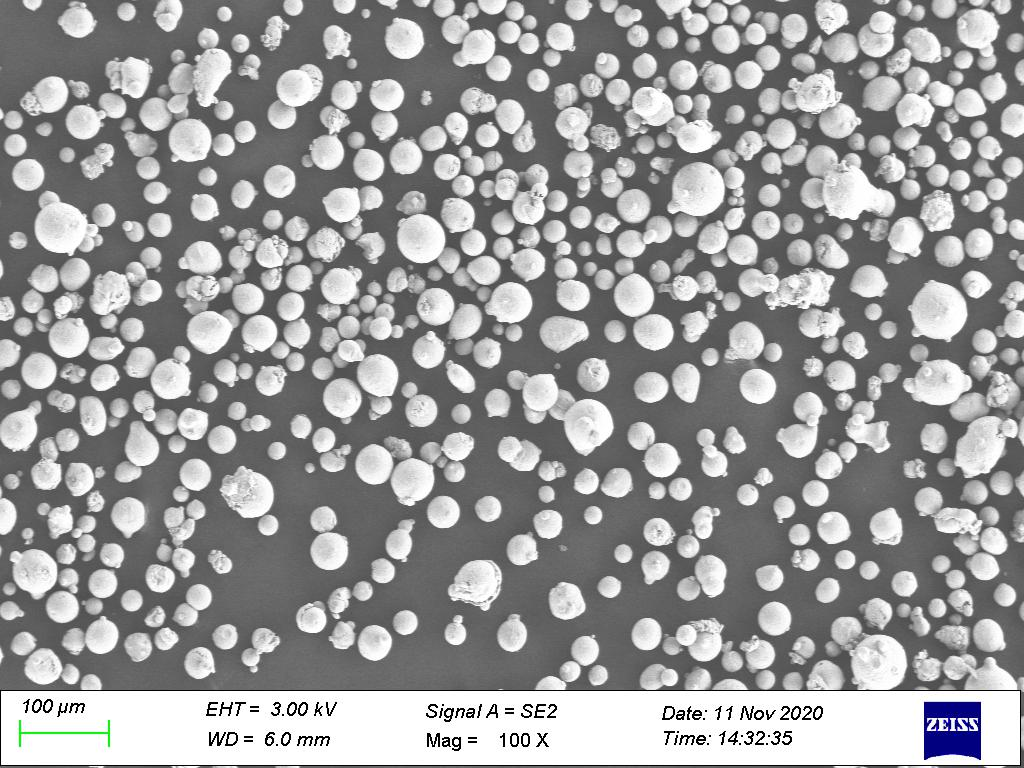

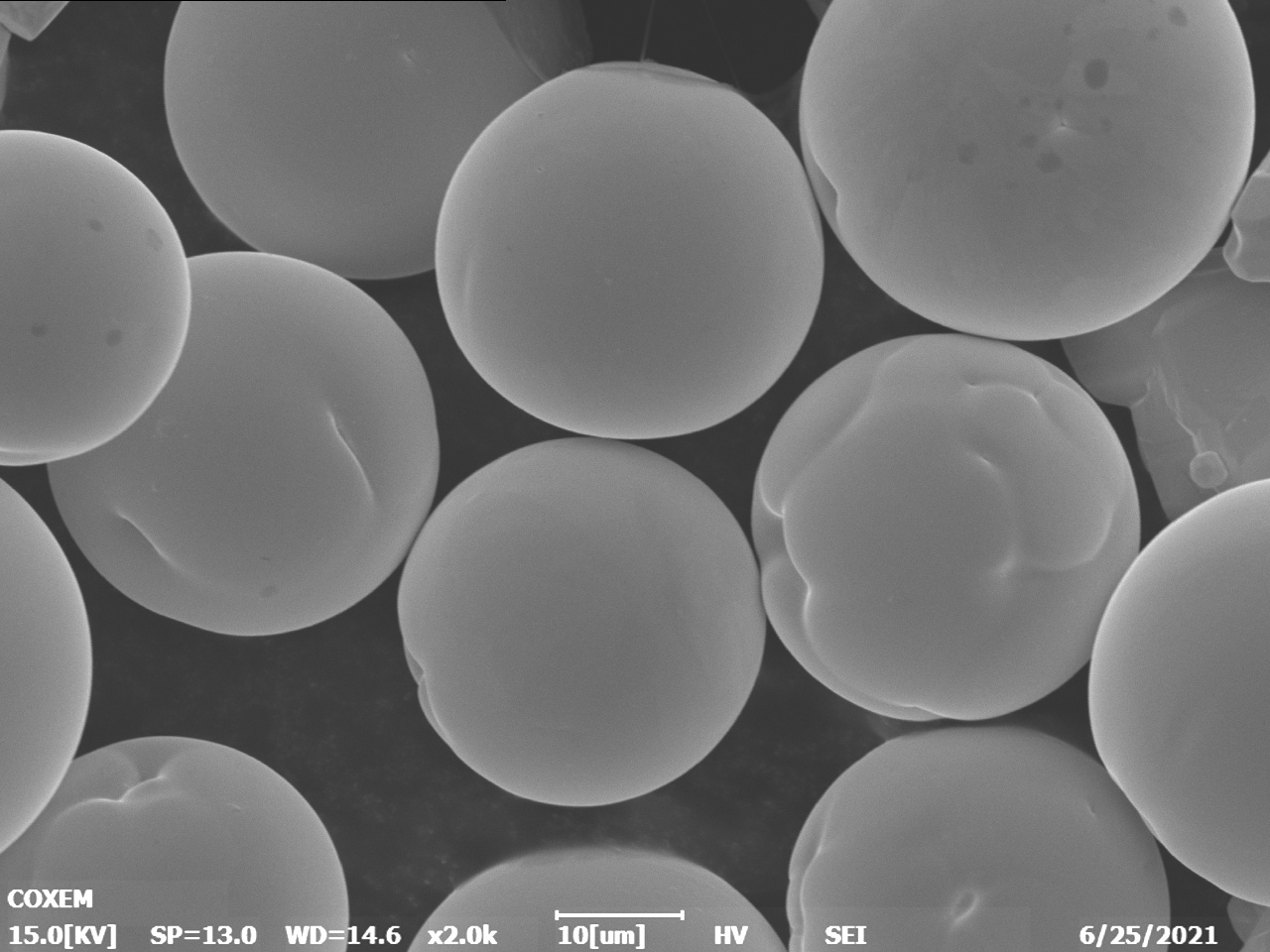

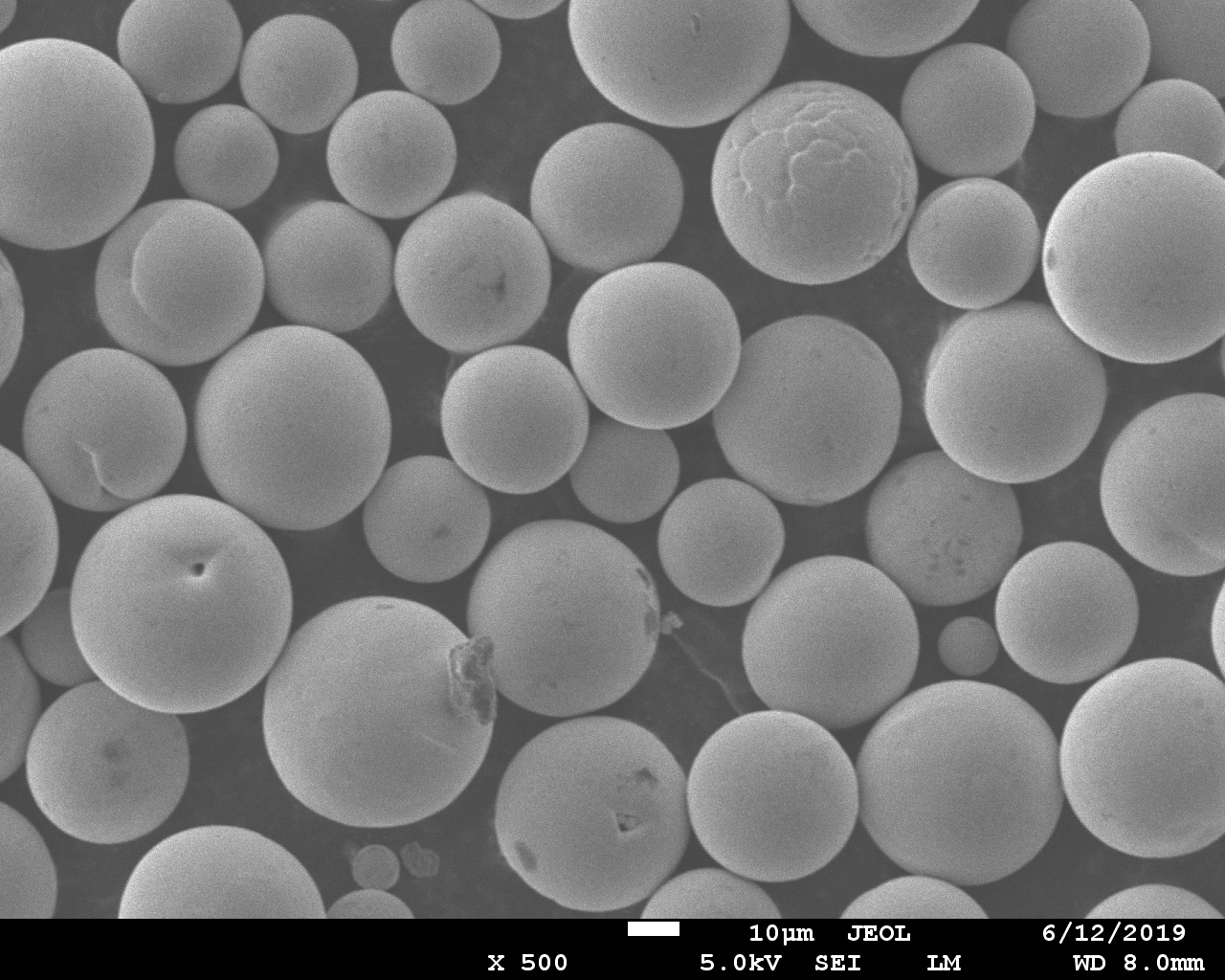

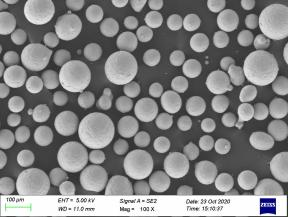

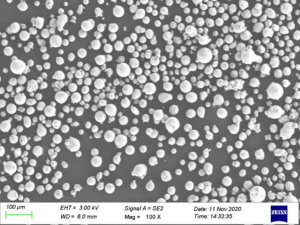

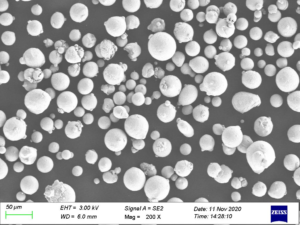

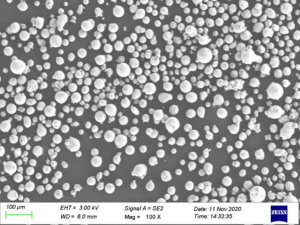

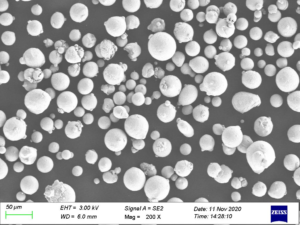

3 Bilder der SEM-Morphologie des Pulvers

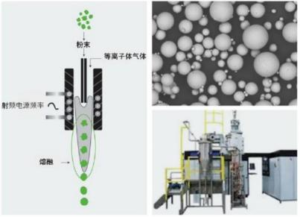

Bilder von Produktion und Test:

Bilder von Produktion und Test:

4.Anwendung

4.Anwendung

| Chemische Zusammensetzung (wt.%) | |||||||||

| Element | C | Cr | Ni | Co | Mo | Al | Ti | Fe | B |

| Standard | 0.05~0.15 | 20.0~24.0 | Bal. | ≤5.0 | 1.0~3.0 | 0.2~0.5 | ≤0.10 | 1.5~2.0 | ≤0.015 |

| typisch | 0.071 | 21.43 | Bal. | 2.01 | 2.02 | 0.33 | 0.06 | 1.76 | 0.0046 |

| Element | Mn | P | S | Cu | W | Si | La | O | N |

| Standard | 0.3~1.0 | ≤0.02 | ≤0.003 | ≤0.50 | 13.0~15.0 | 0.25~0.45 | 0.005~0.05 | ≤0.030 | ≤0.030 |

| typisch | 0.46 | 0.01 | 0.001 | 0.015 | 14.0 | 0.34 | 0.032 | 0.0092 | 0.002 |

| GH3230 | 15~53μm Partikelgrößenverteilung | Durchflussrate (sec. für 50 g) | Scheinbare Dichte (g/cm3) | Klopfdichte (g/cm3) | ||

| D10 | D50 | D90 | ||||

| Standard | 15~25 | 30~40 | 50~60 | ≤25 | ≥4.2 | ≥4.9 |

| typisch | 23μm | 35.8μm | 53.5μm | 15.2 | 4.62 | 5.33 |

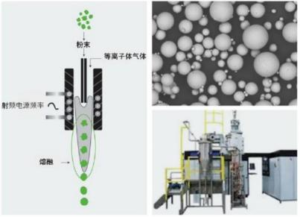

Bilder von Produktion und Test:

Bilder von Produktion und Test:

4.Anwendung

4.Anwendung

- GH3230 alloy can be used to manufacture combustion chambers, flame tubes, heat exchangers, and other components of aviation turbine engines. It can also be used to manufacture combustion chamber components of ground gas turbines and high-temperature equipment components such as thermocouple protective sleeves and flame baffles for industrial furnaces.