Sphärische Metallpulver Titan-Aluminium-Legierung (TiAl) Pulver

Produktcharakter:

TiAl titanium alloy has low density, good mechanical properties, and excellent corrosion resistance, and is widely used in aerospace, shipbuilding, military and other fields. TiAl titanium alloy powder solves a series of problems in additive manufacturing processes, and can achieve high-strength, large-sized, and lightweight components through additive manufacturing processes rapid prototyping manufacturing.

| Markenname | Jinchun |

| Herkunft | China |

| Name des Produkts | Spherical Titanium Aluminum Alloy (TiAl) powder |

| Anmeldung | 3D printing in aerospace, shipbuilding, military and other fields. |

| Form | Pulver |

| Farbe | Metal gray |

| Größe | 15~53μm, 53~150μm, or customized. |

| Standard | GB/T 19001-2016/ISO9001: 2015 |

| Reinheit | Ti: Bal. Al: 33.5~35.0% |

| Material | Ti, Al |

| Verpacken | Vakuumverpackung |

PRODUKT DETAIL

PRODUKT DETAIL

Produkt Charakter

TiAl titanium alloy has low density, good mechanical properties, and excellent corrosion resistance, and is widely used in aerospace, shipbuilding, military and other fields. TiAl titanium alloy powder solves a series of problems in additive manufacturing processes, and can achieve high-strength, large-sized, and lightweight components through additive manufacturing processes rapid prototyping manufacturing.

2.Spezifikation

Spherical Titanium Aluminum Alloy (TiAl) Powder

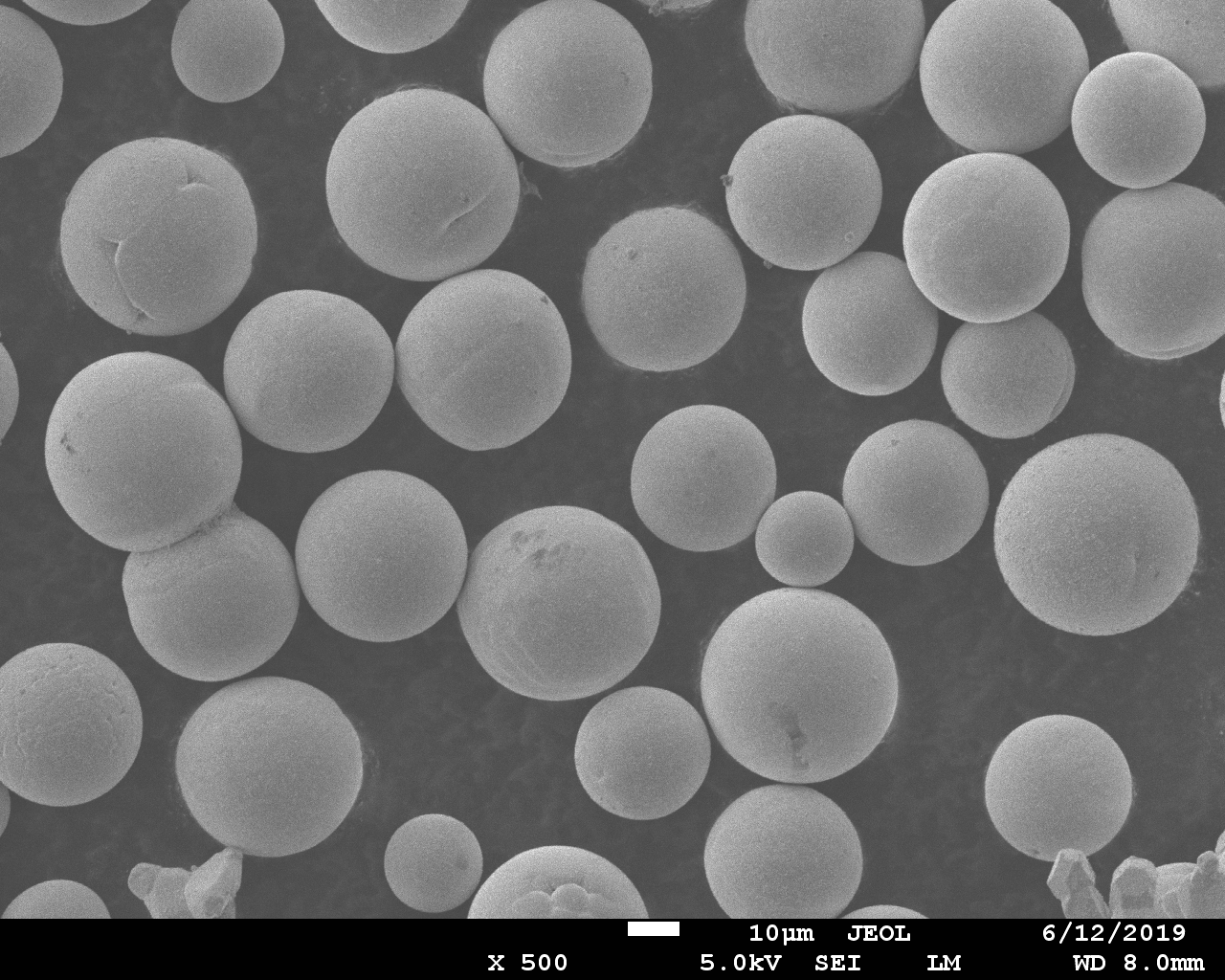

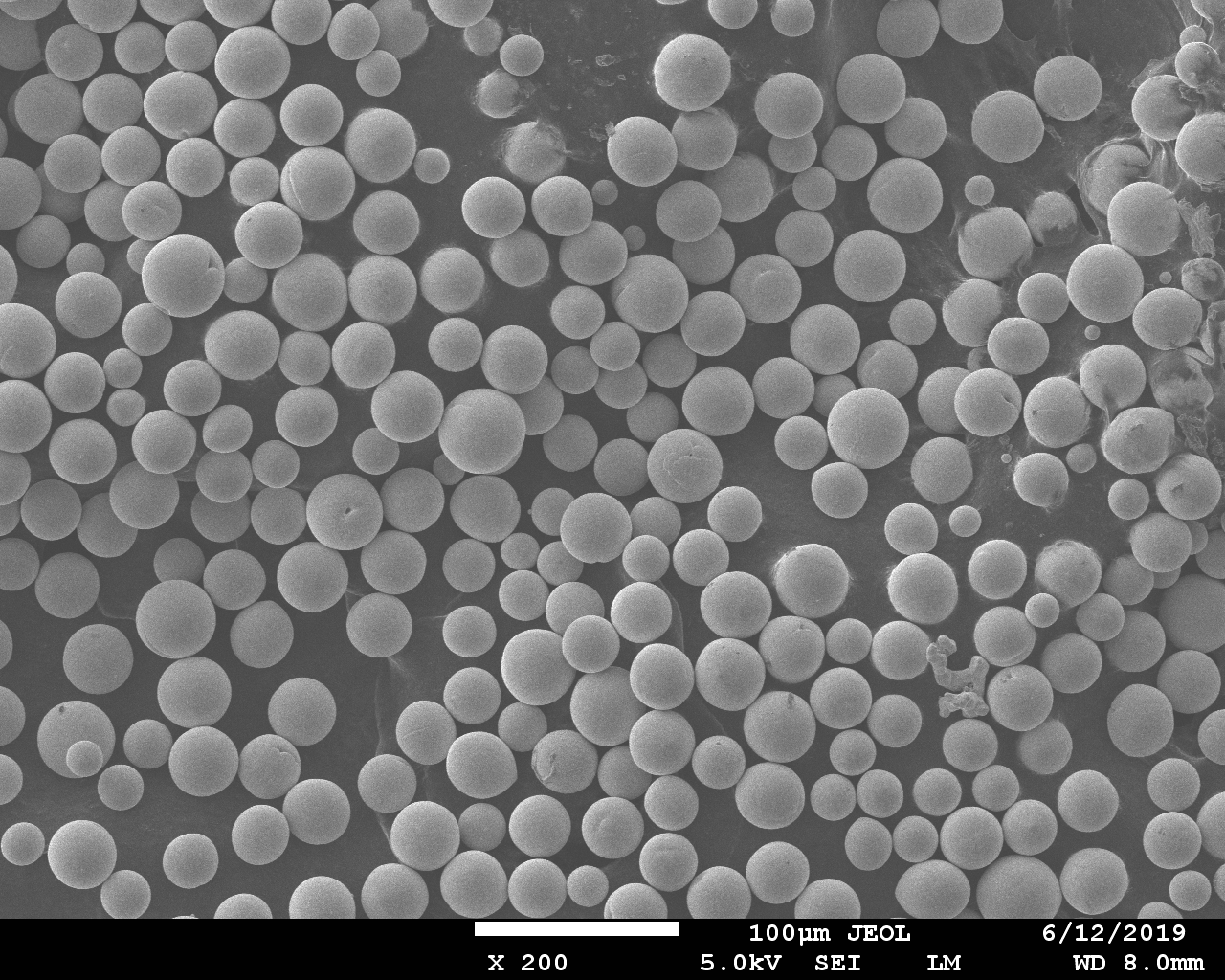

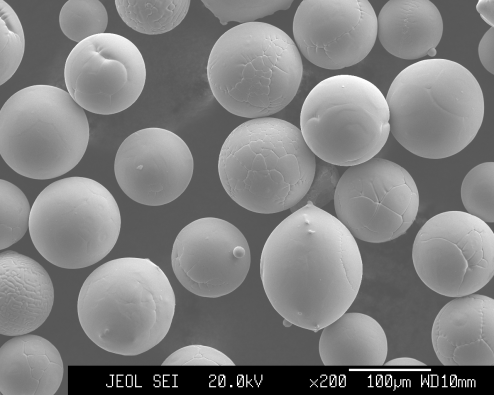

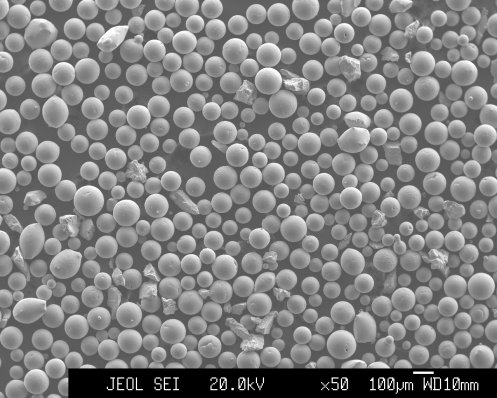

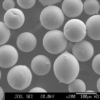

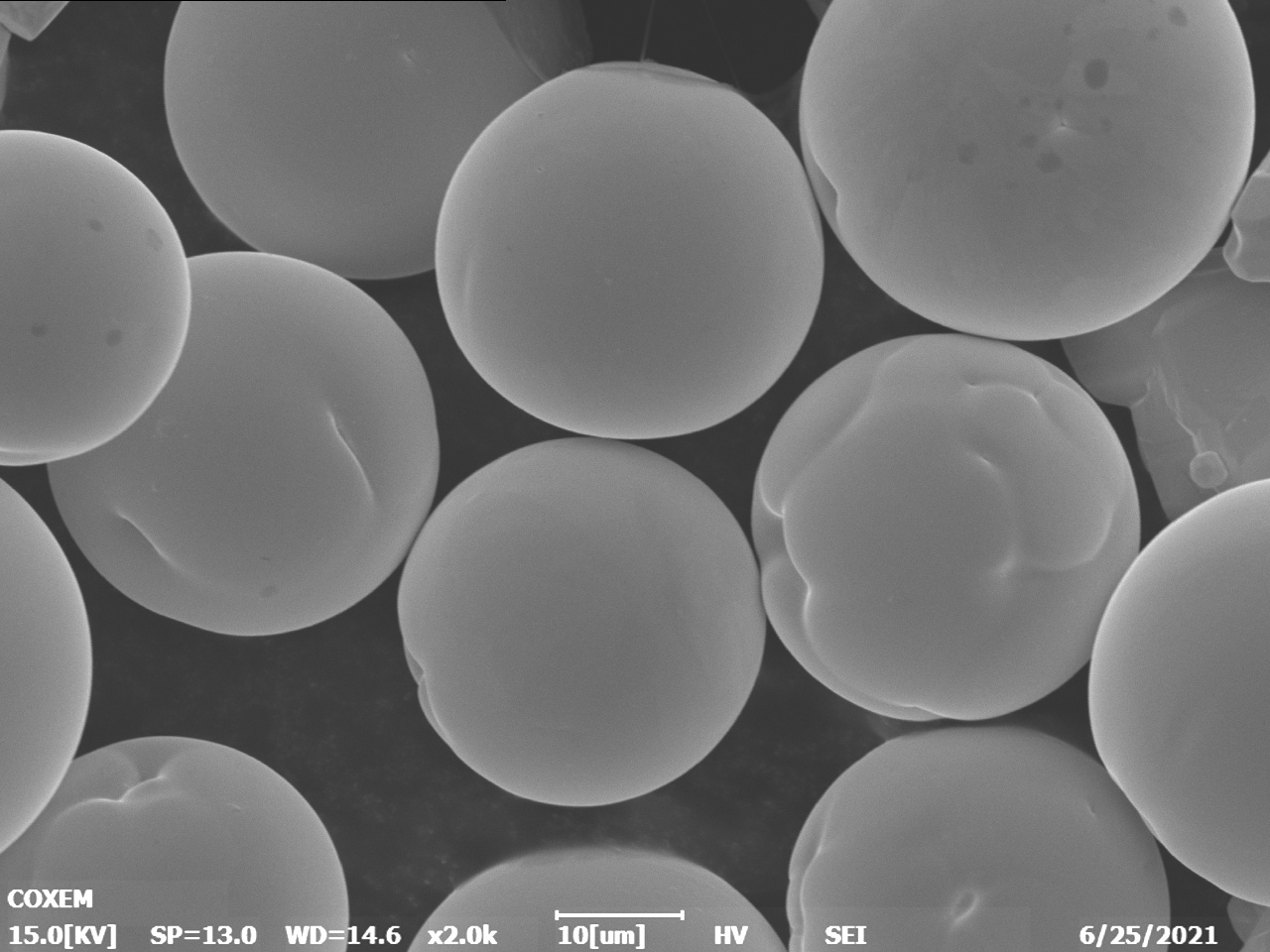

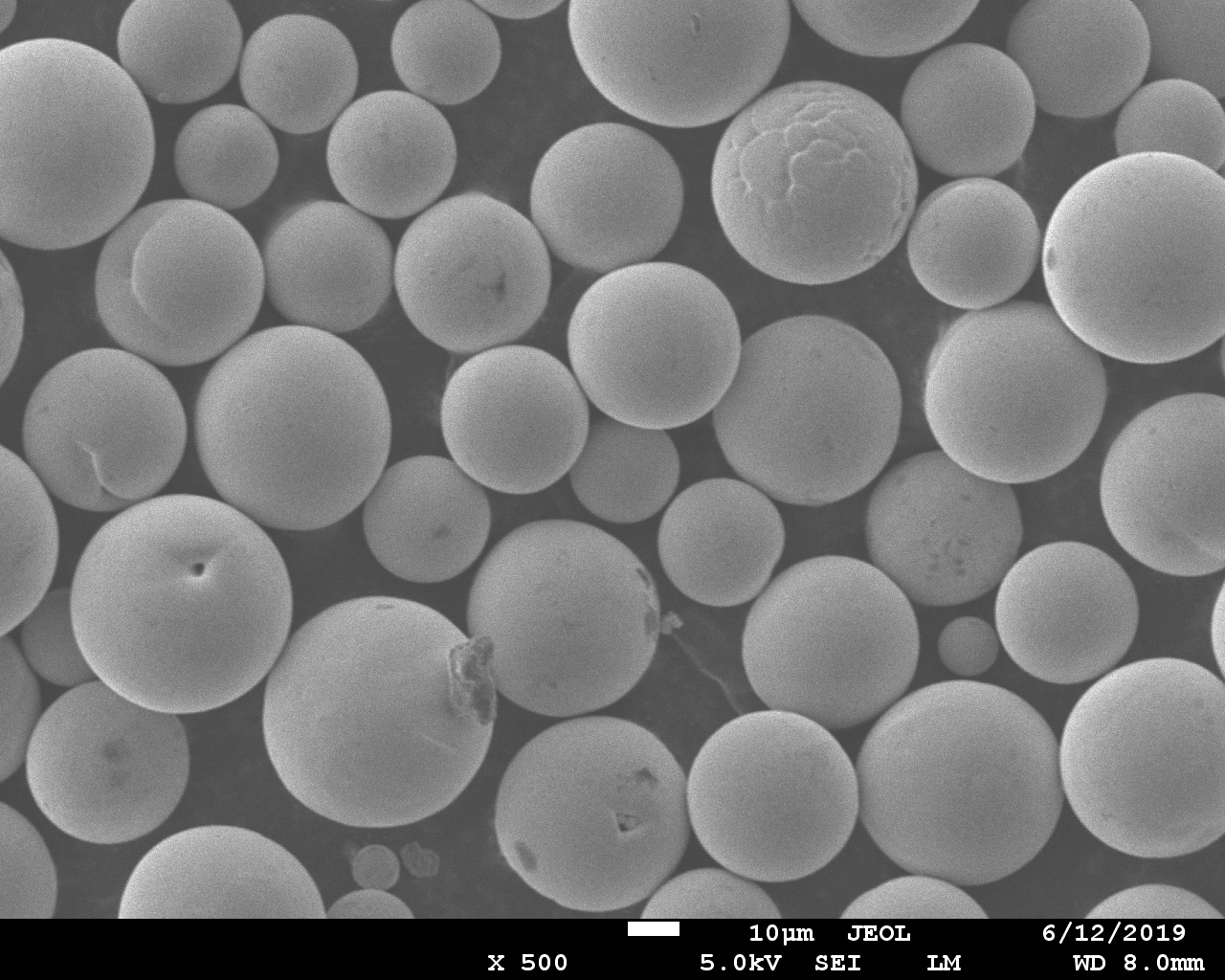

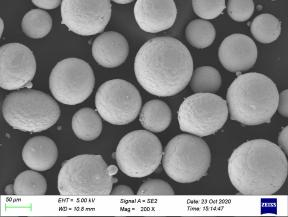

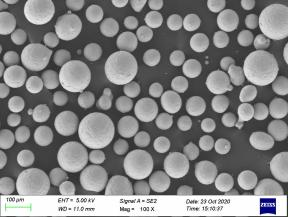

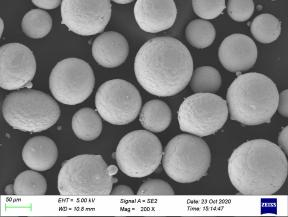

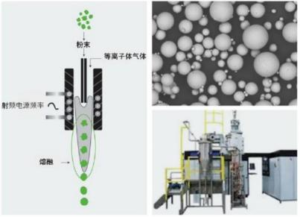

3 Bilder der SEM-Morphologie des Pulvers

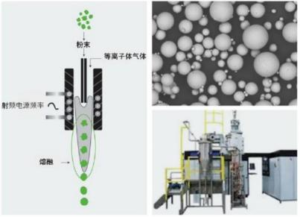

Bilder von Produktion und Test:

Bilder von Produktion und Test:

4.Anwendung

4.Anwendung

| Chemische Zusammensetzung (wt.%) | |||||||||

| Element | Ti | Al | Cr | Nb | Fe | C | N | H | O |

| Standard | Bal. | 33.5~35.0 | 2.5~2.9 | 4.6~5.0 | ≤0.08 | ≤0.02 | ≤0.03 | ≤0.002 | ≤0.10 |

| typisch | Bal. | 34 | 2.6 | 4.8 | 0.005 | 0.0005 | 0.0033 | 0.0008 | 0.026 |

| Spherical TiAl powder | 15~53μm Partikelgrößenverteilung | Durchflussrate (sec. für 50 g) | Scheinbare Dichte (g/cm3) | Klopfdichte (g/cm3) | ||

| D10 | D50 | D90 | ||||

| Standard | 25~35 | 30~40 | 50~60 | ≤42 | ≥2.10 | ≥2.40 |

| typisch | 31.2μm | 39.7μm | 50.6μm | 19.53 | 3.64 | 4.81 |

| Spherical TiAl powder | 53~150μm Partikelgrößenverteilung | Durchflussrate (sec. für 50 g) | Scheinbare Dichte (g/cm3) | Klopfdichte (g/cm3) | ||

| D10 | D50 | D90 | ||||

| Standard | 50~60 | 100~110 | 140~150 | ≤42 | ≥2.10 | ≥2.40 |

| typisch | 50,3μm | 101,2μm | 142,0μm | 12.5 | 3.76 | 4.45 |

Bilder von Produktion und Test:

Bilder von Produktion und Test:

4.Anwendung

4.Anwendung

- Spherical TiAl is suitable for processes of 3D printing in aerospace, shipbuilding, military and other fields.