Sphärische Metallpulver Wolfram (W)-Pulver

Produktcharakter:

Tungsten has excellent high temperature resistance and radiation shielding properties, and is widely used in fields such as defense industry and medical equipment. Spherical tungsten powder is suitable for processes such as laser/electron beam additive manufacturing, laser direct deposition, hot isostatic pressing, injection molding, and laser cladding.

| Markenname | Jinchun |

| Herkunft | China |

| Name des Produkts | Spherical Tungsten powder |

| Anmeldung | Laser/electron beam additive manufacturing, laser direct deposition, hot isostatic pressing, injection molding, and laser cladding etc. |

| Form | Pulver |

| Farbe | Metall schwarz |

| Größe | ≤20μm, 5~20μm, 5~25μm, 15~53μm, 53~150μm, 15~45μm, 45~106μm, or customized. |

| Standard | GB/T 19001-2016/ISO9001: 2015 |

| Reinheit | W: 99.95% min |

| Material | Tungsten |

| Verpacken | Vakuumverpackung |

PRODUKT DETAIL

PRODUKT DETAIL

Produkt Charakter

Tungsten has excellent high temperature resistance and radiation shielding properties, and is widely used in fields such as defense industry and medical equipment. Spherical tungsten powder is suitable for processes such as laser/electron beam additive manufacturing, laser direct deposition, hot isostatic pressing, injection molding, and laser cladding.

2.Spezifikation

Spherical Tungsten Powder

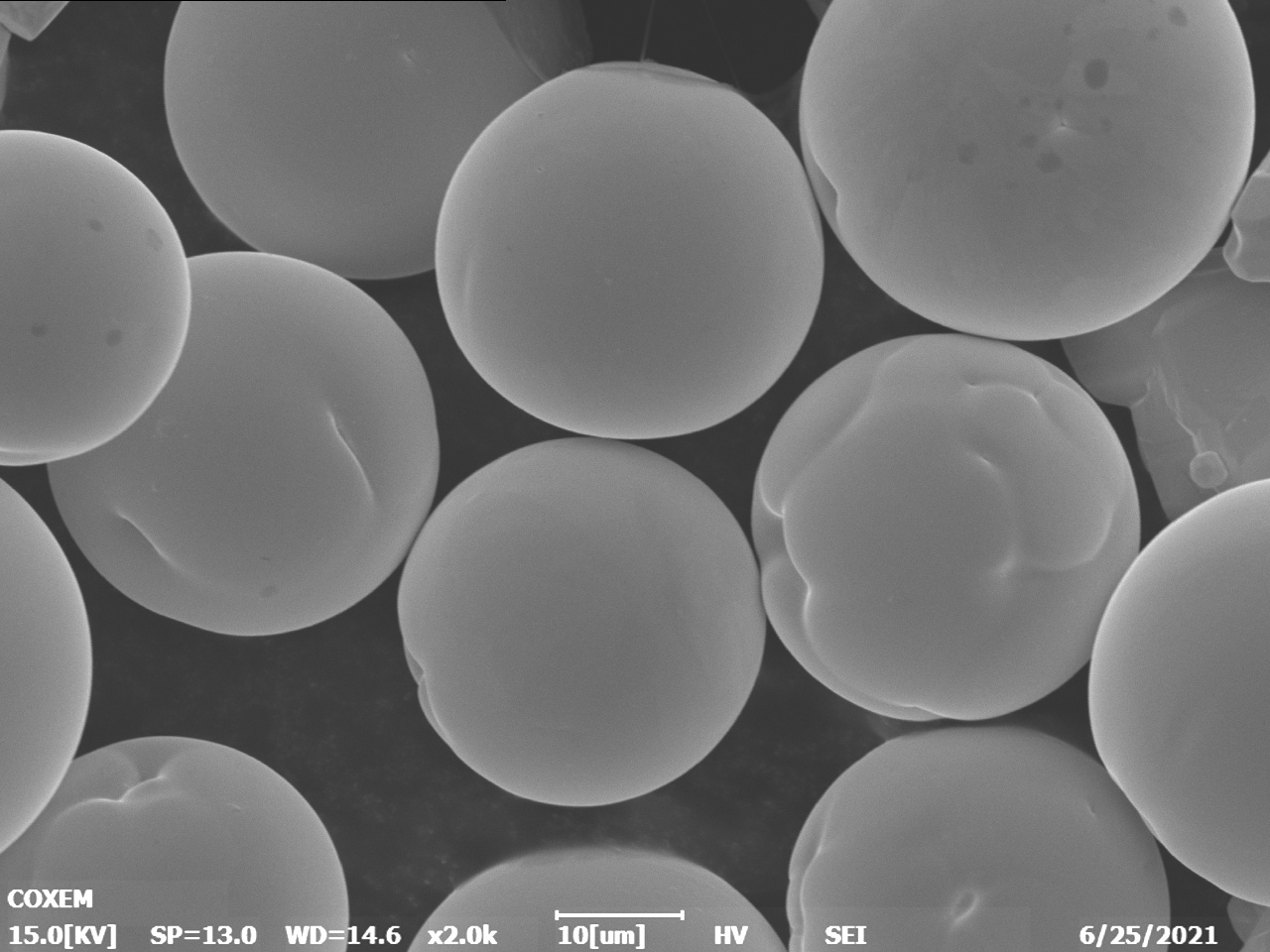

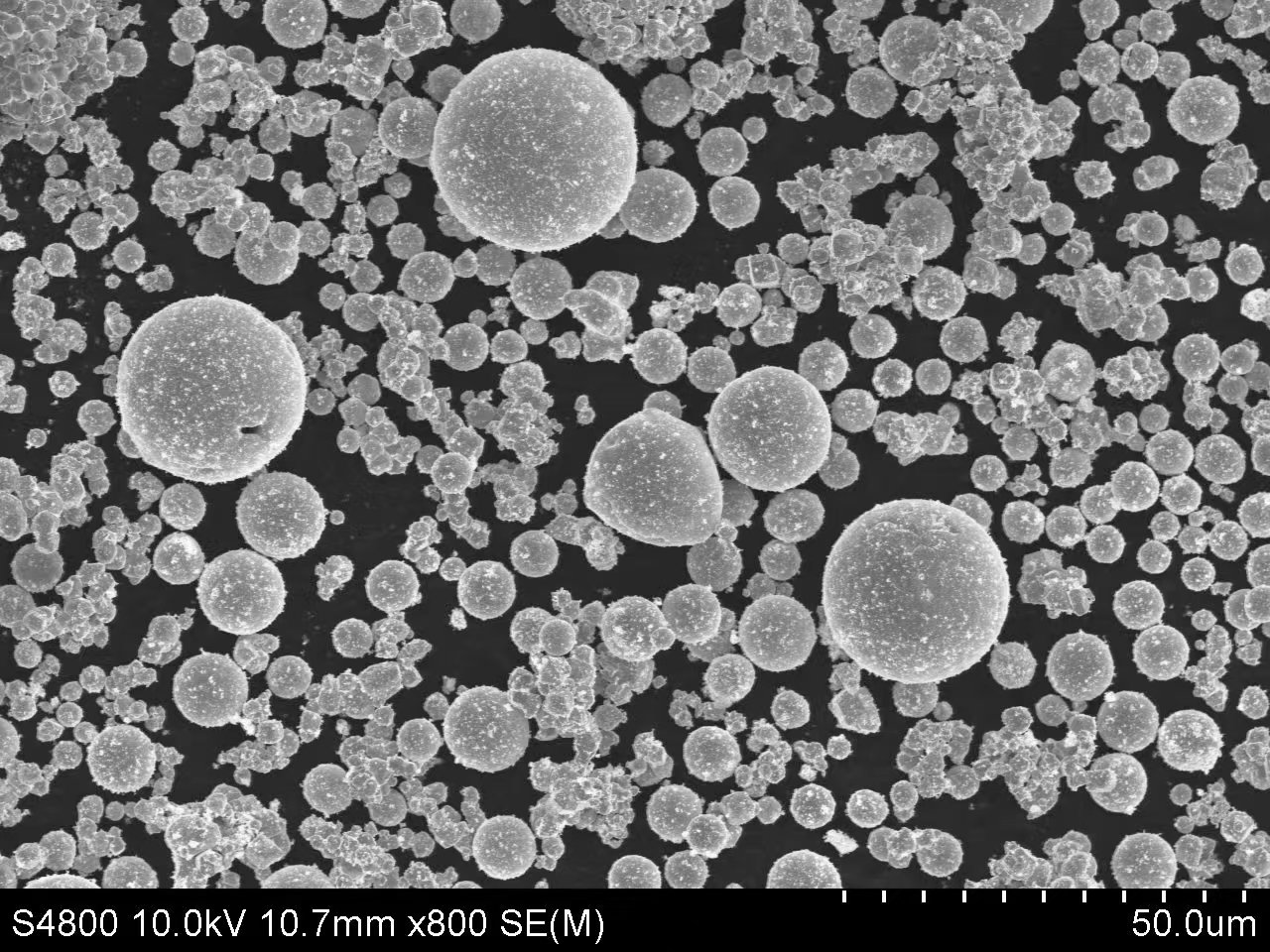

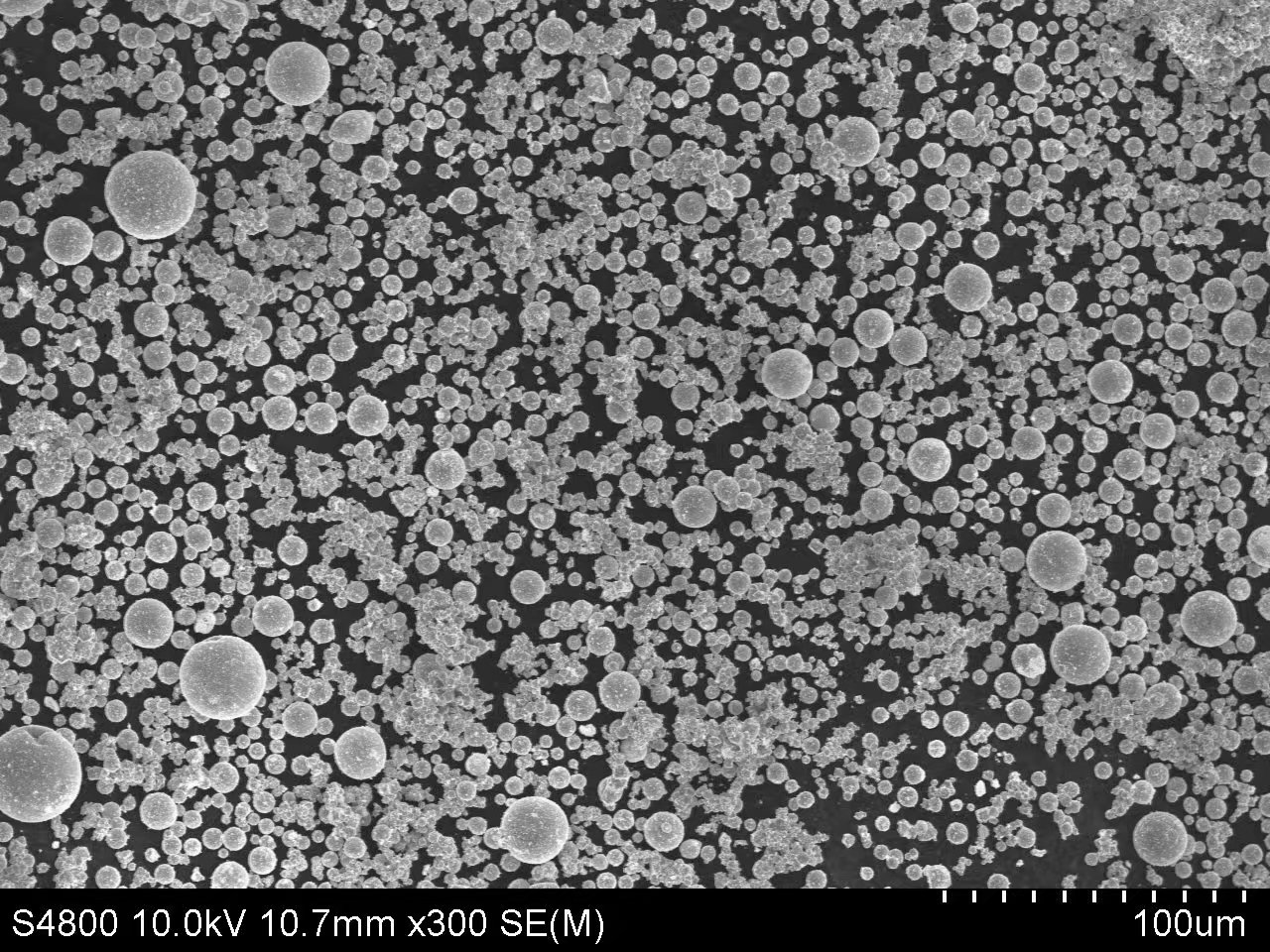

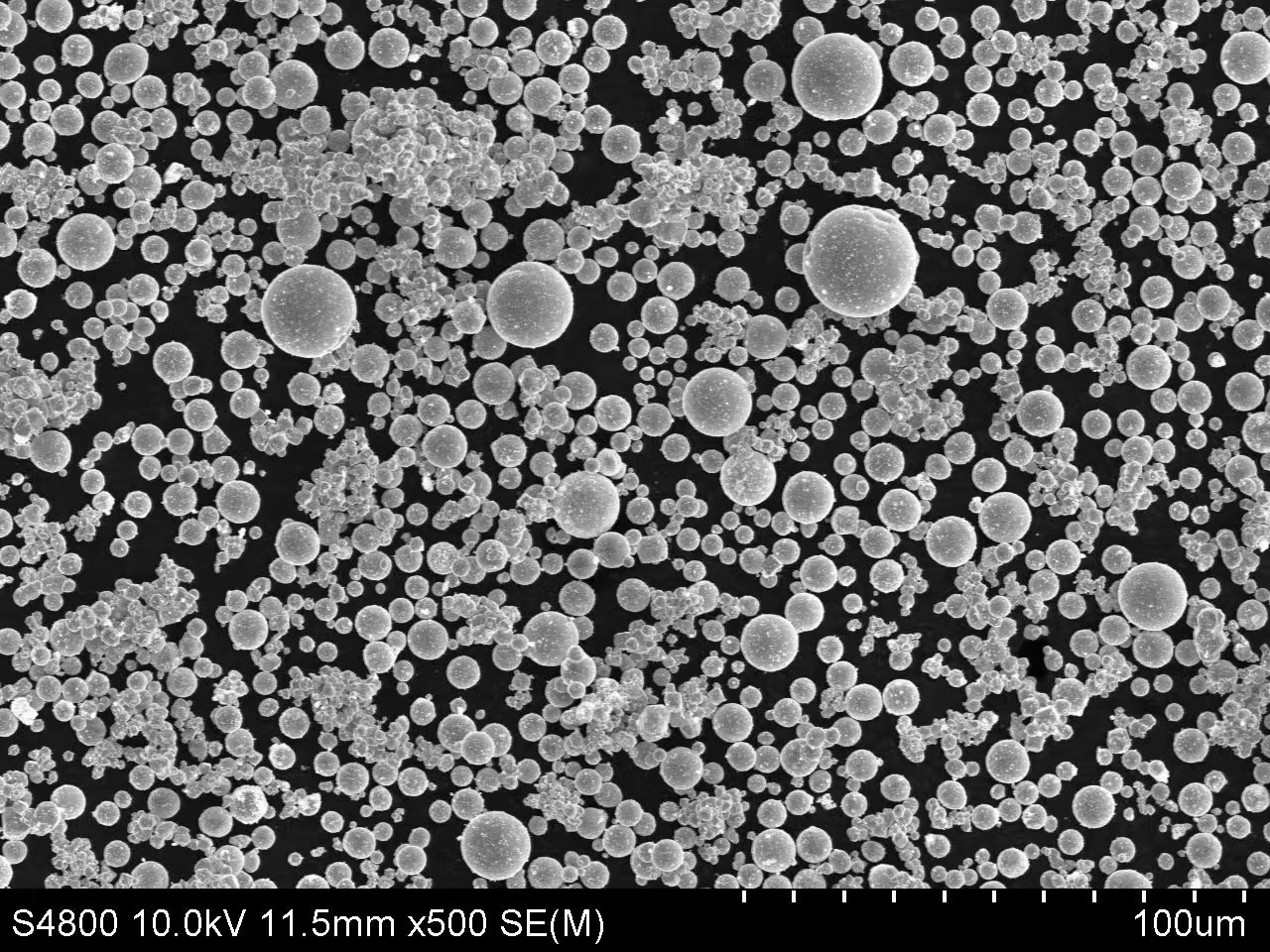

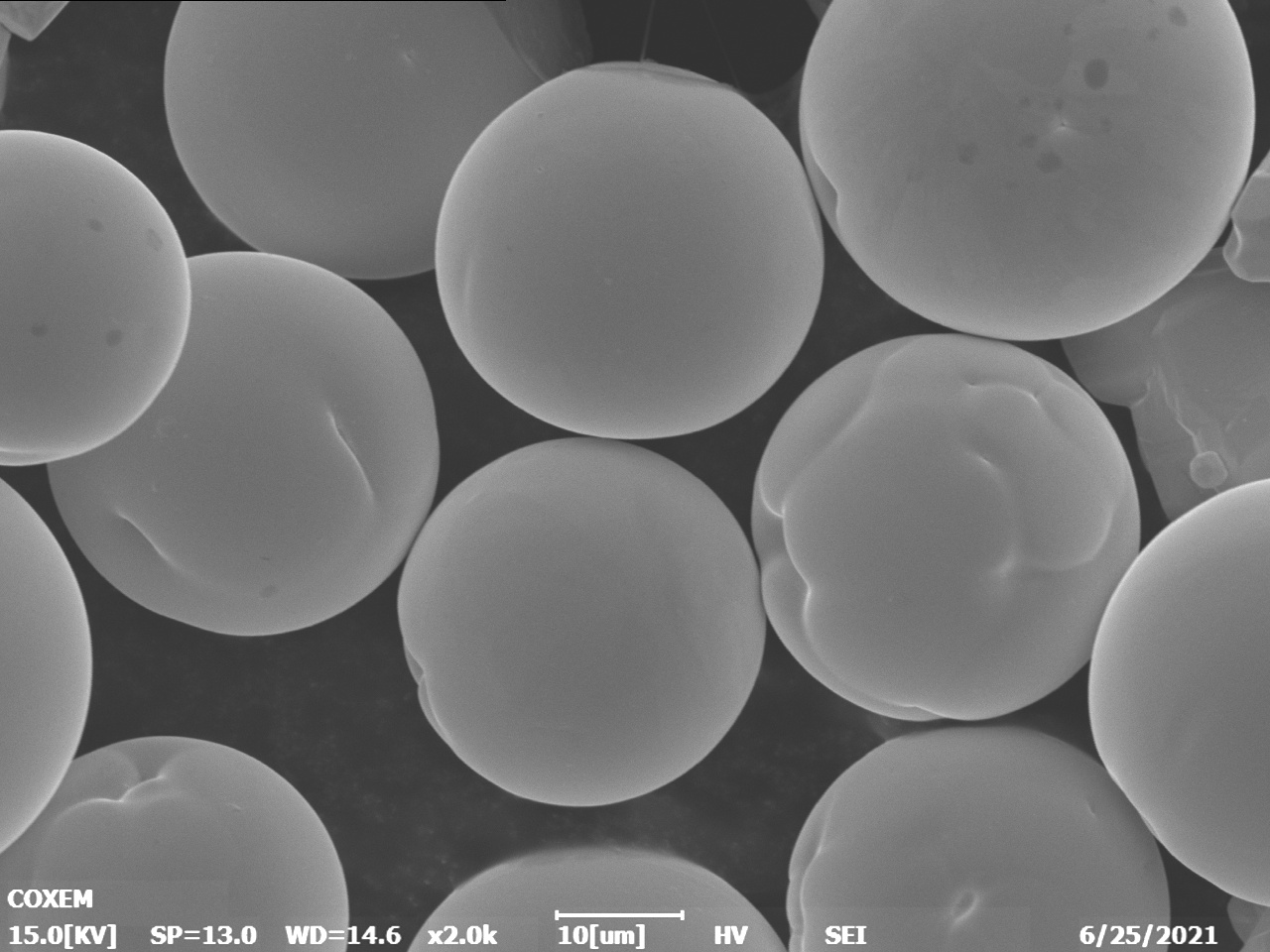

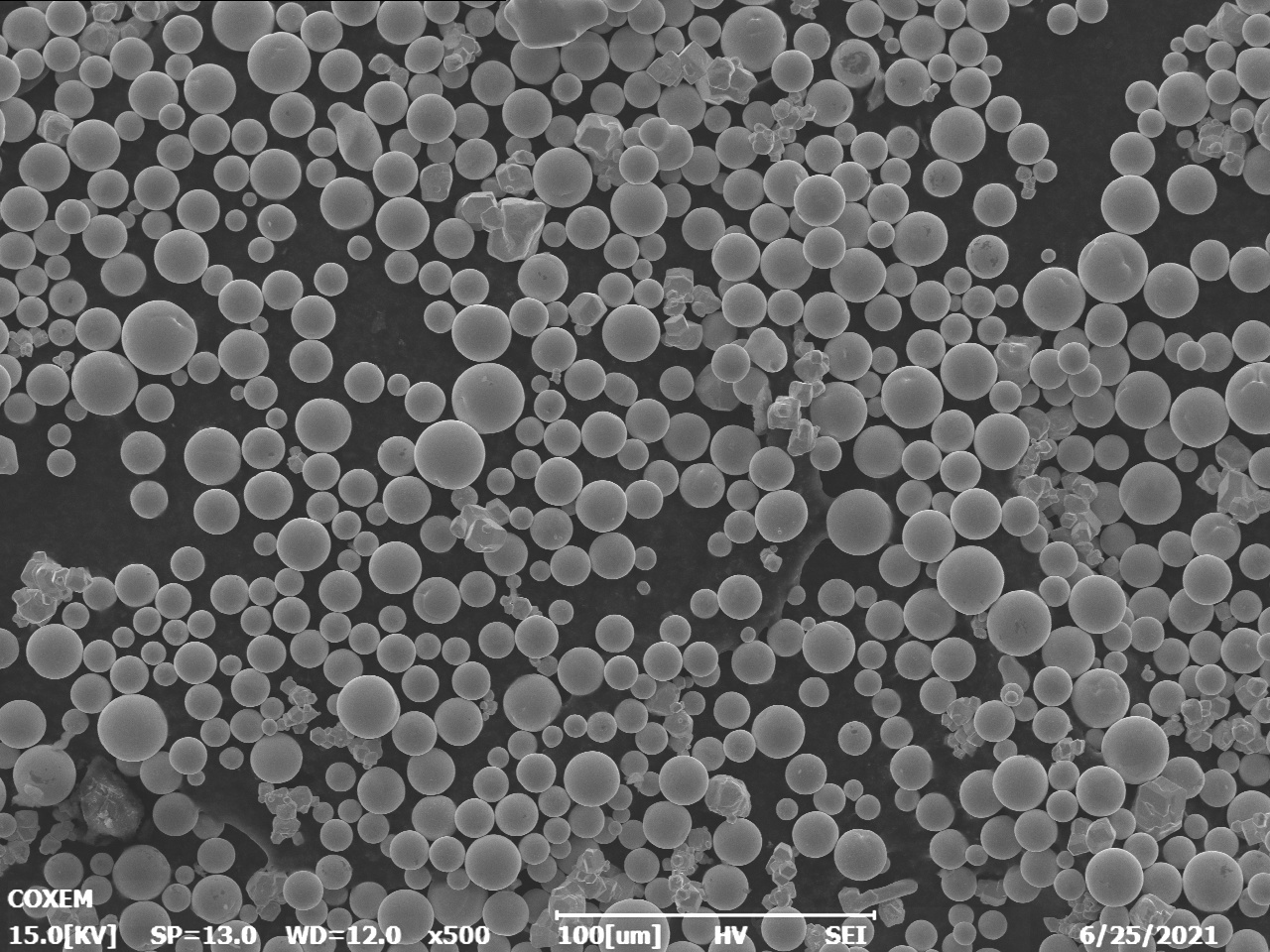

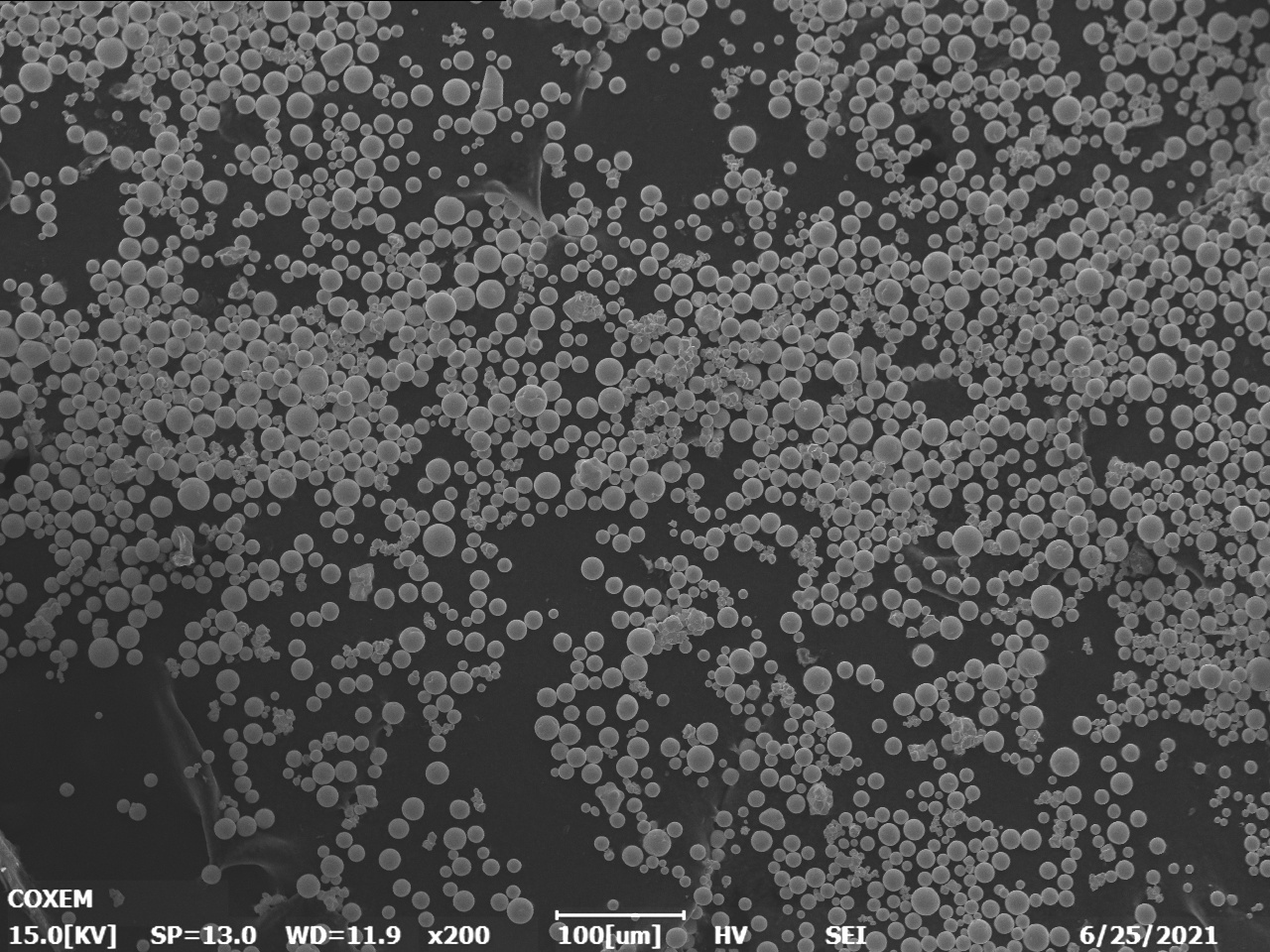

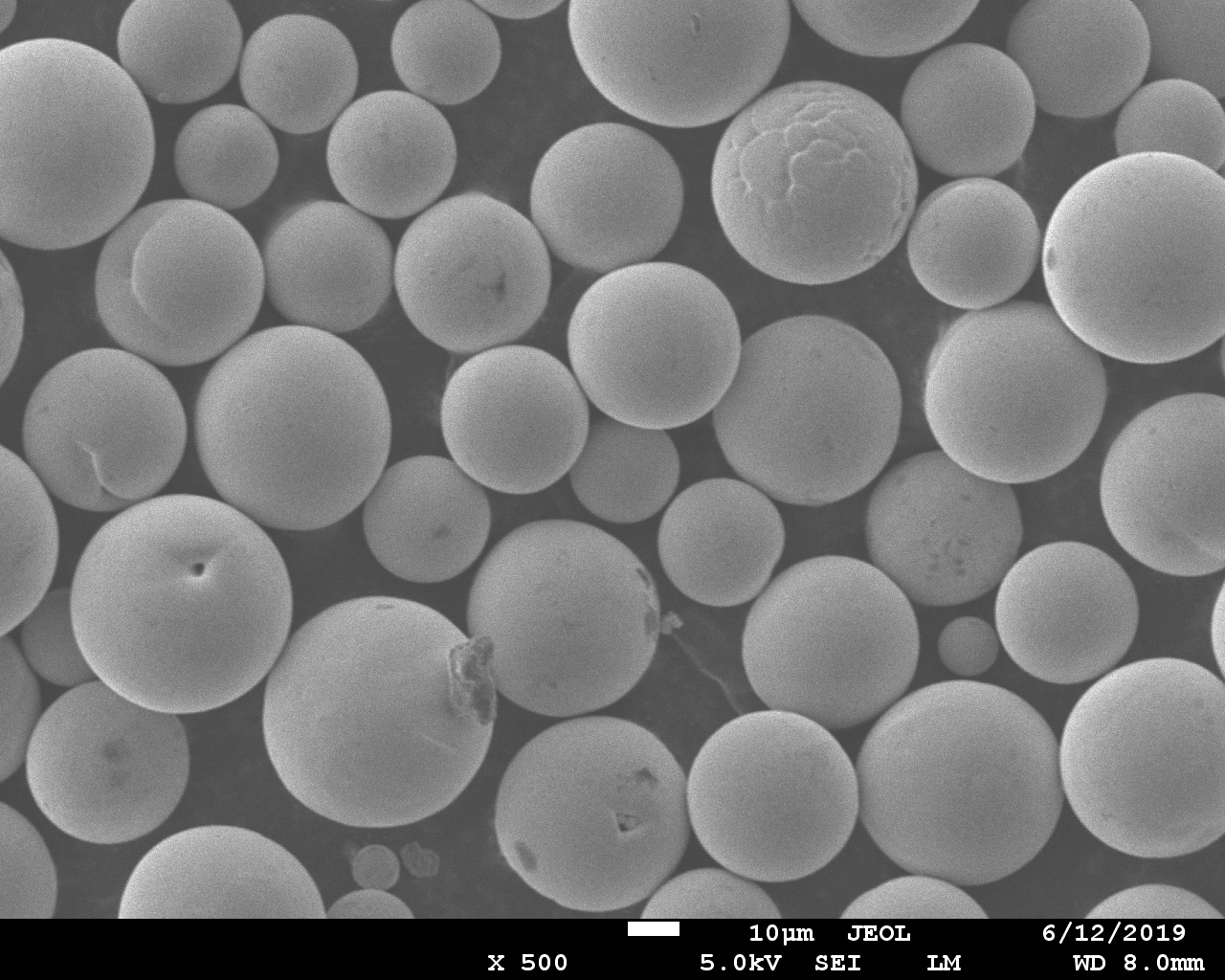

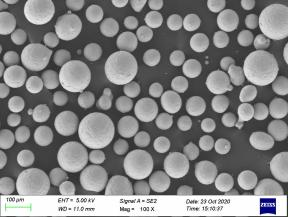

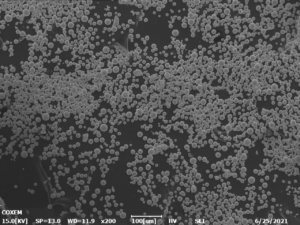

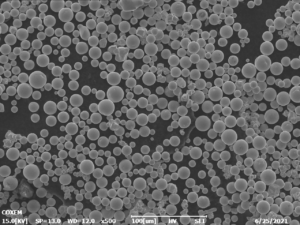

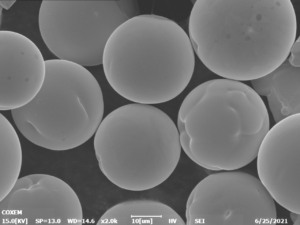

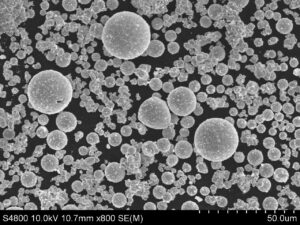

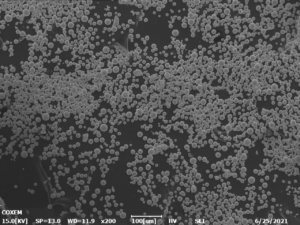

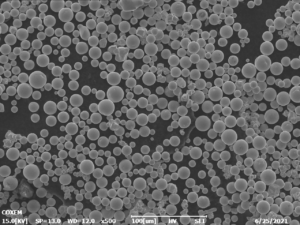

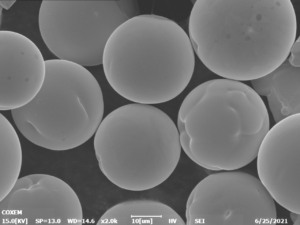

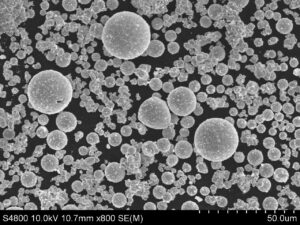

3 Bilder der SEM-Morphologie des Pulvers

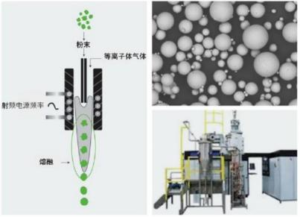

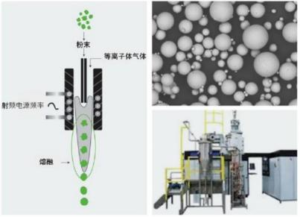

Bilder von Produktion und Test:

Bilder von Produktion und Test:

4.Anwendung

4.Anwendung

| Chemische Zusammensetzung (Gew.-ppm) | |||||||||

| Element | Ni | Mo | Cu | Bi | Cr | Mg | Sb | Si | K |

| Standard(≤ppm) | 50 | 500 | 10 | 5 | 50 | 10 | 10 | 50 | 20 |

| typical(≤ppm) | 6 | 23 | 2 | 4 | 13 | 7 | 3 | 8 | 9 |

| Element | Fe | Ca | Mn | Als | Pb | Al | S | P | W |

| Standard (≤ppm) | 500 | 20 | 10 | 15 | 5 | 10 | 10 | 10 | Bal. |

| typical(≤ppm) | 12 | 5 | 6 | 9 | 3 | 8 | 3 | 8 | Bal. |

| Element | H | O | N | C | |||||

| Standard(≤ppm) | 9 | 200 | 100 | 40 | |||||

| typical(≤ppm) | 8 | 180 | 10 | 20 | |||||

| Spherical Tungsten powder | <20μm Particle Size Distribution | Durchflussrate (sec. für 50 g) | Scheinbare Dichte (g/cm3) | Klopfdichte (g/cm3) | ||

| D10 | D50 | D90 | ||||

| Standard | 1~5 | 5~10 | 10~15 | ≥3.6 | ||

| typisch | 4.46μm | 8.00μm | 14.06μm | 9.5 | ||

| Spherical Tungsten powder | 5~25μm Particle Size Distribution | Durchflussrate (sec. für 50 g) | Scheinbare Dichte (g/cm3) | Klopfdichte (g/cm3) | ||

| D10 | D50 | D90 | ||||

| Standard | 5~10 | 11.5~20 | 20~30 | ≤25 | ≥3.6 | ≥4.8 |

| typisch | 9.2μm | 16.5μm | 25.8μm | 13.1 | 10.46 | 11.53 |

| Spherical Tungsten powder | 15~53μm Partikelgrößenverteilung | Durchflussrate (sec. für 50 g) | Scheinbare Dichte (g/cm3) | Klopfdichte (g/cm3) | ||

| D10 | D50 | D90 | ||||

| Standard | 20~30 | 30~40 | 50~60 | ≤25 | ≥3.6 | ≥4.8 |

| typisch | 19,3μm | 31,5μm | 50,0μm | 6.1 | 10.54 | 12.48 |

| Spherical Tungsten powder | 53~150μm Partikelgrößenverteilung | Durchflussrate (sec. für 50 g) | Scheinbare Dichte (g/cm3) | Klopfdichte (g/cm3) | ||

| D10 | D50 | D90 | ||||

| Standard | 50~60 | 100~110 | 140~150 | ≤25 | ≥3.6 | ≥4.3 |

| typisch | 50,3μm | 101,2μm | 142,0μm | 4.5 | 10.43 | 12.11 |

Bilder von Produktion und Test:

Bilder von Produktion und Test:

4.Anwendung

4.Anwendung

- Spherical tungsten powder is suitable for processes such as laser/electron beam additive manufacturing, laser direct deposition, hot isostatic pressing, injection molding, and laser cladding.