Welding Consumables Metal Materials High Carbon Medium Carbon Low Carbon ferro manganese powder

Carácter del producto:

According to the different carbon contents, ferromanganese powder can be divided into 3types: high carbon, medium, low carbon ferromanganese. As the carbon content decreases, the manganese content will increase.

| Marca | Jinchun |

| Origen | China |

| Nombre del producto | High carbon ferro manganese, medium carbon ferro manganese, low carbon ferro manganese powder |

| Aplicación | Welding rods, Alloy additive,Electromagnetic materials,Magnetic material,Powder metallurgy,Other fields |

| Forma | Polvo |

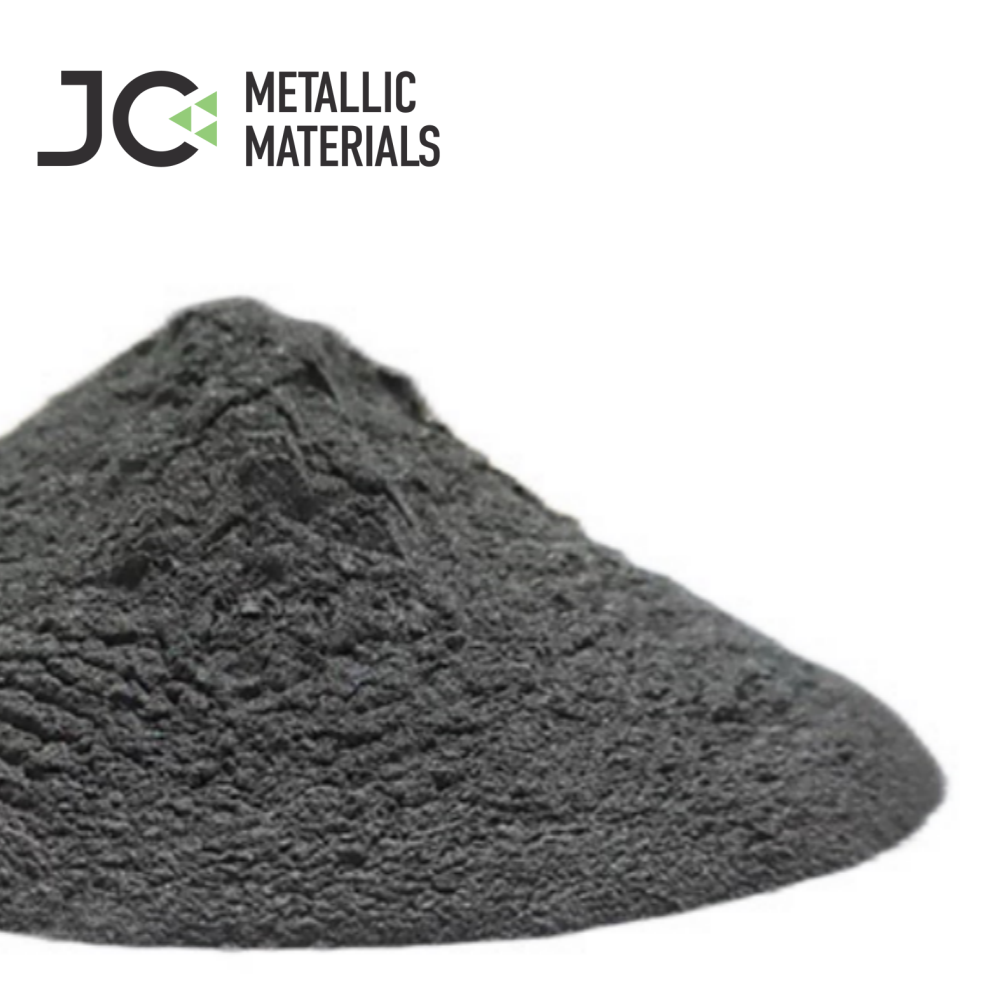

| Color | Metal negro |

| Talla | Malla 40, malla 60, malla 80, malla 100, malla 200, malla 300, malla 325 |

| Estándar | GB/T 19001-2016/ISO9001: 2015 |

| Pureza | High carbon: Mn 75%, C6.5%; Medium carbon: Mn79% , C1.5%; Low carbon: Mn:80%, C 0.5% |

| Material | Ferro manganese lump |

| Embalaje | Ton bags, steel drums |

DETALLE DEL PRODUCTO

DETALLE DEL PRODUCTO

Carácter del producto

According to the different carbon contents, ferromanganese powder can be divided into 3types: high carbon, medium, low carbon ferromanganese. As the carbon content decreases, the manganese content will increase.

2.Especificación

High carbon ferro manganese powder

Medium carbon ferro manganese powder

Low carbon ferro manganese powder

3.Fotos de materias primas y producción

Imágenes de materias primas:

Fotos de la producción:

Fotos de la producción:

4.Aplicación

Ferro manganese powder has multiple uses and a wide range of applications, playing an important role in material processing, electronic manufacturing, magnetic materials and other fields. The main uses of manganese iron powder are as follows:

4.Aplicación

Ferro manganese powder has multiple uses and a wide range of applications, playing an important role in material processing, electronic manufacturing, magnetic materials and other fields. The main uses of manganese iron powder are as follows:

| Nombre/ Tipo | Elemento | Mn | C | Si | P | S |

| FeMn78C8.0 | Estándar(%) | 75.0~82.0 | ≤8.0 | ≤1.5 | ≤0.20 | ≤0.03 |

| Resultado(%) | 75.32 | 6.65 | 1.10 | 0.11 | 0.022 |

| Nombre/ Tipo | Elemento | Mn | C | Si | P | S |

| FeMn78C2.0 | Estándar(%) | 75.0~82.0 | ≤2.0 | ≤1.5 | ≤0.20 | ≤0.03 |

| Resultado(%) | 79.49 | 1.33 | 1.20 | 0.14 | 0.01 |

| Nombre/ Tipo | Elemento | Mn | C | Si | P | S |

| FeMn84C0.7 | Estándar(%) | 75.0~82.0 | ≤0.7 | ≤1.0 | ≤0.20 | ≤0.02 |

| Resultado(%) | 80.10 | 0.52 | 0.78 | 0.08 | 0.02 |

Fotos de la producción:

Fotos de la producción:

4.Aplicación

Ferro manganese powder has multiple uses and a wide range of applications, playing an important role in material processing, electronic manufacturing, magnetic materials and other fields. The main uses of manganese iron powder are as follows:

4.Aplicación

Ferro manganese powder has multiple uses and a wide range of applications, playing an important role in material processing, electronic manufacturing, magnetic materials and other fields. The main uses of manganese iron powder are as follows:

- Alloy additive: Ferro manganesepowder, as an important alloy additive, plays a role in enhancing strength, hardness, and wear resistance in materials such as steel and cast iron. It can improve the heat treatment performance of alloys, making them have better tensile and compressive resistance, which helps to enhance the overall performance of materials.

- Electromagnetic materials: Ferro manganese powder, as an important electromagnetic material, has a wide range of applications in electronics, communication, power supply and other fields. It has good conductivity and anti magnetic properties, and can be used to manufacture electromagnetic components such as inductors, electromagnetic coils, transformers, etc., which helps to improve the performance and stability of electronic products.

- Magnetic material: Ferro manganese powder has good magnetic properties and can be used to manufacture magnetic components such as magnetic cores, motors, sensors, etc. It has the advantages of high saturation magnetic induction intensity and low magnetic permeability, which can improve the efficiency and performance of magnetic components.

- Powder metallurgy: Ferro manganese powder is an ideal powder metallurgy raw material that can be used to manufacture various powder metallurgy products, such as powder metallurgy parts, magnetic materials, metal artworks, etc. Through powder metallurgy technology, parts with complex shapes and precise dimensions can be prepared, which helps to improve manufacturing efficiency and save costs.

- Other fields: Ferro manganese powder can also be used to prepare high-performance welding rods, coatings, abrasives and other products, widely used in metal processing, aerospace, automotive manufacturing, mechanical manufacturing and other fields. At the same time, it can also serve as a functional material such as catalyst, adsorbent, and preservative, which helps improve the characteristics and performance of the material. In summary, due to its unique physical and chemical properties, ferro manganese powder plays an important role in multiple fields and is one of the indispensable materials in modern industrial production.

-