Exploring the Cost Benefits of Cobalt Base Alloy Powder in High-Temperature Application

How Does Jinchun’s Cobalt Base Alloy Powder Perform in High-Temperature Applications?

Jinchun, a leading manufacturer of metal powders, specializes in cobalt base alloy powder, a critical material used in high-temperature applications across various industries. Cobalt-based alloys are well known for their exceptional heat resistance, strength, and ability to retain mechanical properties in extreme environments, making them ideal for demanding conditions such as those found in gas turbines, aerospace, power generation, and automotive industries.

Jinchun’s cobalt base alloy powder is engineered to withstand high temperatures without losing its structural integrity. These alloys possess excellent oxidation and corrosion resistance, ensuring that components made from them perform reliably in high-stress environments. The material’s ability to resist thermal fatigue and wear also makes it invaluable in manufacturing parts such as turbine blades, exhaust valves, and heat exchangers that operate at elevated temperatures.

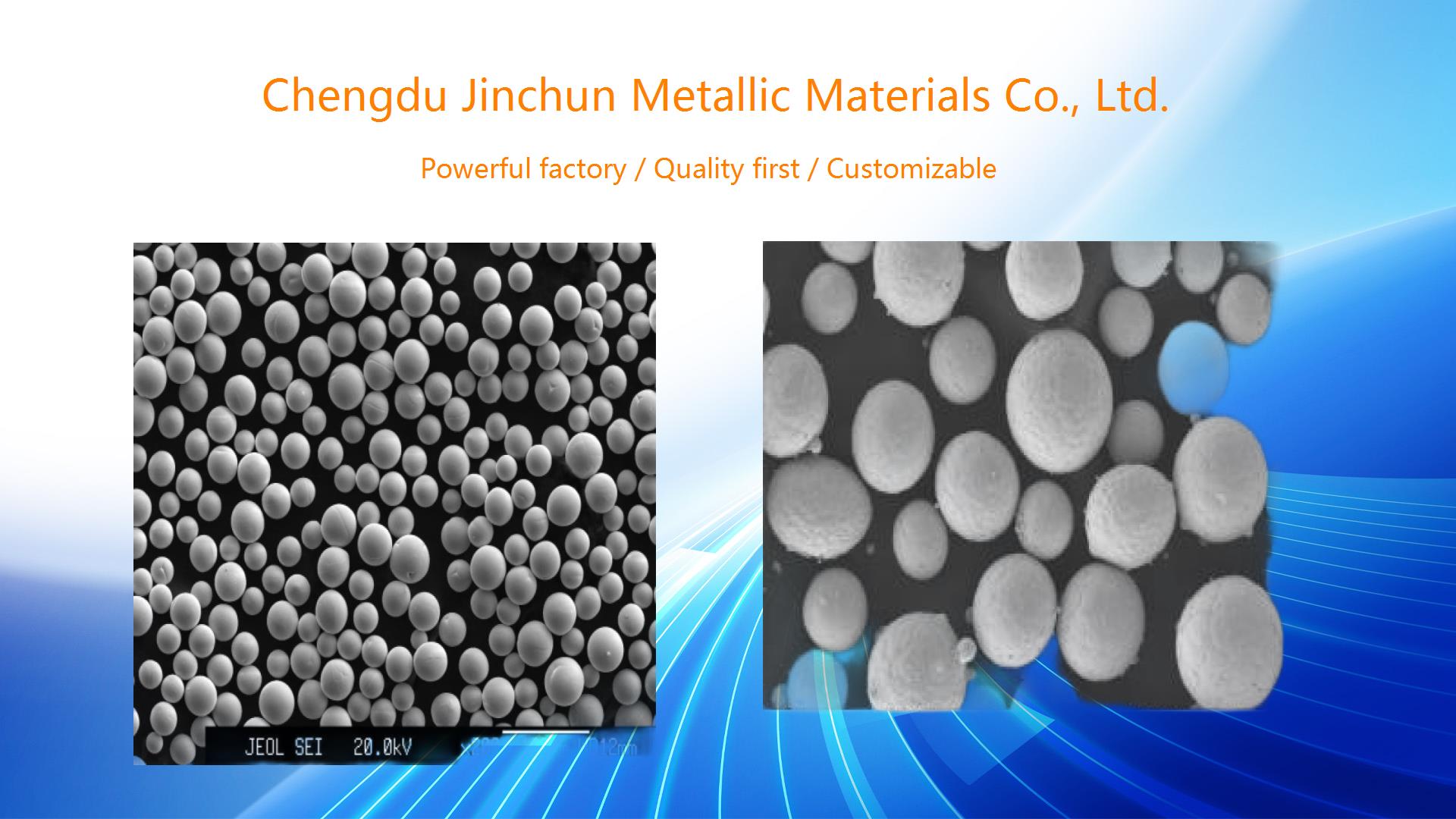

In addition to its superior thermal properties, Jinchun’s cobalt base alloy powder offers enhanced wear resistance, making it particularly useful in applications where parts are exposed to both abrasion and high heat. The powder is also used for additive manufacturing, powder metallurgy, and thermal spray coatings, providing high-quality results in various fabrication processes. Jinchun ensures that the alloy powder is produced with consistent particle size and purity, delivering reliable and repeatable performance in demanding industrial applications.

What Are the Cost Benefits of Using Jinchun’s Cobalt Base Alloy Powder?

Jinchun’s cobalt base alloy powder provides significant cost advantages for industries that require high-performance materials in extreme conditions.

Durability and Longevity

One of the primary cost benefits of cobalt base alloy powder is its durability. The material’s ability to withstand high temperatures and corrosive environments means that parts manufactured using Jinchun’s cobalt base alloy powder tend to have a longer lifespan compared to those made from other metals. This results in lower maintenance costs and fewer replacements, making it a cost-effective choice for companies operating in high-temperature environments.

For example, in industries such as power generation or aerospace, where equipment is subject to extreme heat and stress, the durability of cobalt base alloys ensures that critical components like turbine blades or exhaust systems last longer, reducing downtime and the need for frequent repairs or replacements. This extended service life translates into significant cost savings over time.

Performance Efficiency and Reduced Material Usage

Another cost benefit lies in the performance efficiency of Jinchun’s cobalt base alloy powder. The superior mechanical properties of cobalt alloys mean that less material is required to achieve the desired performance compared to other alloys. The ability to use thinner components without compromising strength or heat resistance allows manufacturers to reduce material costs while maintaining high-performance standards.

Moreover, Jinchun’s cobalt base alloy powder can be applied through thermal spraying or additive manufacturing, which are more material-efficient processes. These methods allow for precise application, minimizing waste and reducing the overall cost of raw materials. This makes cobalt base alloy powder an attractive option for industries looking to maximize performance while managing material costs.

Resistance to Wear and Corrosion

Jinchun’s cobalt base alloy powder is highly resistant to both wear and corrosion, making it a valuable material in industries where components are exposed to abrasive conditions and chemical degradation. This resistance reduces the frequency of part failure due to erosion or oxidation, lowering operational costs over time. By investing in cobalt-based components, companies can avoid costly downtimes associated with equipment failure or part degradation, further contributing to long-term cost savings.

Peer Product Comparison: How Does Jinchun’s Cobalt Base Alloy Powder Compare to Other High-Temperature Alloys?

When compared to other high-temperature materials such as nickel-based alloys or stainless steel, Jinchun’s cobalt base alloy powder offers distinct advantages in both performance and cost-effectiveness.

Heat Resistance and Performance

Nickel-based alloys, while commonly used in high-temperature applications, tend to lose strength when exposed to sustained high temperatures. In contrast, Jinchun’s cobalt base alloy powder maintains its mechanical properties over a wider range of temperatures, making it more suitable for extreme environments such as those found in aerospace and turbine applications. While nickel-based alloys may be less expensive upfront, the long-term durability and enhanced performance of cobalt alloys lead to greater cost savings over time.

Wear and Corrosion Resistance

Compared to stainless steel, which is often used for its corrosion resistance, cobalt base alloys provide superior resistance in high-temperature environments, especially when exposed to abrasion or thermal cycling. Stainless steel may degrade faster under intense heat and wear conditions, whereas Jinchun’s cobalt alloys maintain their integrity, reducing the frequency of part replacements. This makes cobalt base alloys a more economical choice in applications where both heat and wear resistance are crucial.

Material and Process Efficiency

In terms of manufacturing processes, Jinchun’s cobalt base alloy powder is highly suitable for additive manufacturing and thermal spraying, offering more efficient material use compared to traditional casting or forging methods. This results in lower production costs and less material waste, further contributing to the cost-effectiveness of using cobalt base alloys for high-temperature applications.

Conclusion

Jinchun’s cobalt base alloy powder offers exceptional performance in high-temperature applications, providing significant cost benefits through its durability, efficiency, and resistance to wear and corrosion. When compared to other high-temperature alloys like nickel-based materials or stainless steel, Jinchun’s cobalt alloys demonstrate superior thermal performance and long-term cost savings, making them an ideal choice for industries such as aerospace, power generation, and automotive. With Jinchun’s commitment to producing high-quality, consistent cobalt base alloy powder, companies can optimize their operations while minimizing costs associated with maintenance and material usage.

_6258副本-2.jpg)