Graded impact mill

Crushing

Airflow mill

Airflow mill: Micron silicon powder, other ultra fine metal powders alloy powders are manufactured by airflow mill.

Crushing: Currently, our crushing is mainly used to produce high carbon ferro chrome powder.

Graded impact mill: Chromium metal powder, ferro molybdenum powder, ferro tungsten powder, chromium carbide powder, etc. can be produced with graded impact mill. The characteristics of the powders are size adjustable and gradeable.

Water Atomization

Water atomization: Nickel powder, cobalt powder, stainless steel powder, Tin powder, nickel base alloy powder (Ni60, Ni60A, ETC.), iron base alloy powder (Fe45, Fe55,etc.), cobalt base alloy powder (Co55, etc.), Nickel Chromium alloy powder, Nickel iron alloy powder, iron copper alloy powder, etc. These are widely used in spraying and coating area.

Reduction & Gas Atomization

Reduction: Removing oxygen from compounds and reducing metal oxides with carbon to get pure metals. Our iron powder, zinc powder, niobium powder are manufactured by this.

Gas atomization: The powders produced by gas atomization is in good liquidity, because the powder shape is in spherical shape or spherical like shape .

Vacuum Furnce: Alloy Metal / Powder

Vacuum furnace: Titanium Boron Alloy Lump or Powder, Titanium Silicon Alloy Lump or Powder, Copper Iron Powder, etc. We supply custimized services for different alloy metals.

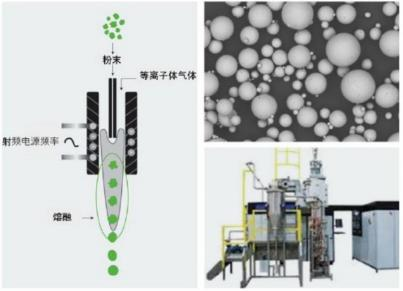

RF Plasma Spheroidization

With the instruction of RF Plasma spheroidization, we mainly produce spherical tantalum powder, spherical niobium powder, spherical tungsten powder, spherical titanium powder, spherical nickel powder, spherical TC4 powder, spherical Tantalum Tungsten alloy powder, TA1, TA15, GH3625, GH3536, GH4169, GH5188, GH3230, GH4099, and other refratory metal or alloy powders.