Poudres métalliques sphériques Poudre de carbure de tungstène coulé (WC)

Caractéristiques du produit:

Spherical cast tungsten carbide powder is suitable for producing wear-resistant coatings through processes such as plasma transfer arc welding (PTA), laser cladding, and thermal spraying due to its unique preparation process and excellent performance. A coating made of spherical cast tungsten carbide as the hard phase and molten nickel, cobalt, and iron alloys as the bonding phase can strengthen the surface of mechanical parts, improve wear resistance, and extend service life. It has broad application prospects in mining, oil drilling, engineering machinery, aerospace and other fields.

| Nom de la marque | Jinchun |

| Origine | Chine |

| Nom du produit | Spherical Cast Tungsten Carbide powder |

| Application | Plasma transfer arc welding (PTA), laser cladding, thermal spraying, etc. |

| Forme | Poudre |

| Couleur | Métal noir |

| Taille | 45-425μm, 45-100μm, <45μm, or customized. |

| Standard | GB/T 19001-2016/ISO9001 : 2015 |

| La pureté | W: 95.0% min |

| Matériau | Cast Tungsten Carbide |

| Emballage | Emballage sous vide |

DÉTAILS DU PRODUIT

DÉTAILS DU PRODUIT

Caractère du produit

Spherical cast tungsten carbide powder is suitable for producing wear-resistant coatings through processes such as plasma transfer arc welding (PTA), laser cladding, and thermal spraying due to its unique preparation process and excellent performance. A coating made of spherical cast tungsten carbide as the hard phase and molten nickel, cobalt, and iron alloys as the bonding phase can strengthen the surface of mechanical parts, improve wear resistance, and extend service life. It has broad application prospects in mining, oil drilling, engineering machinery, aerospace and other fields.

2. cahier des charges

Spherical Cast Tungsten Carbide Powder

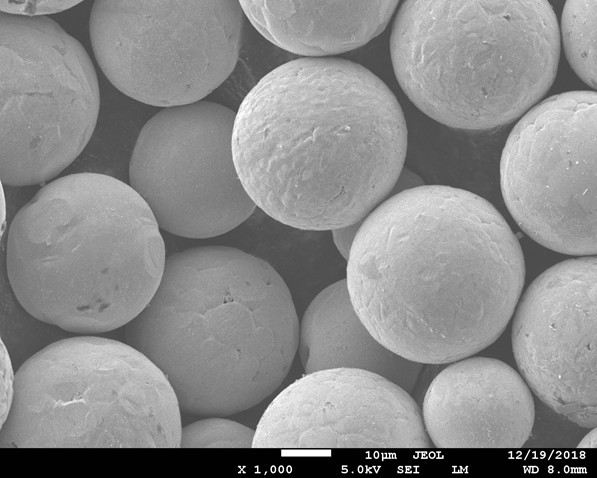

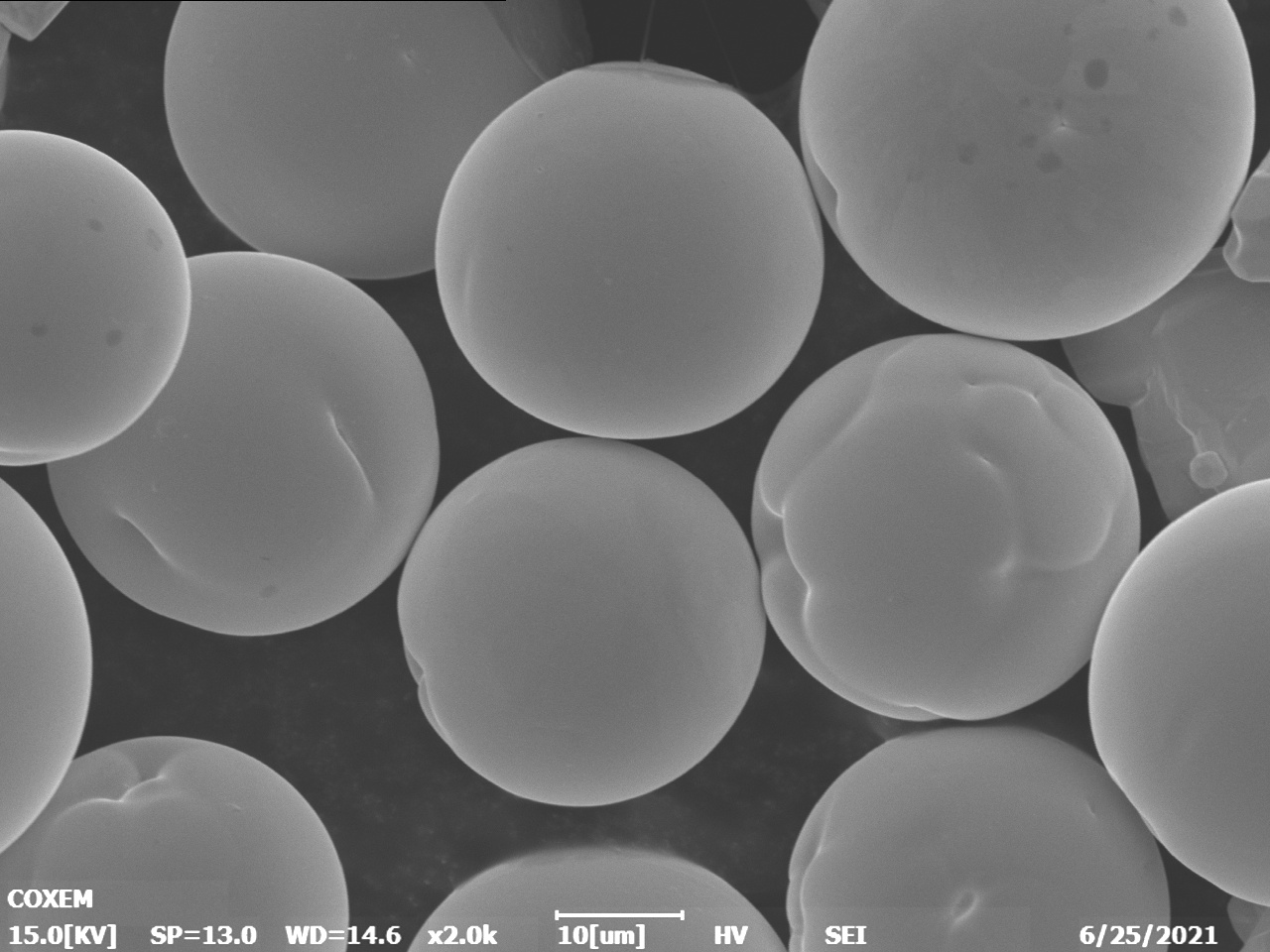

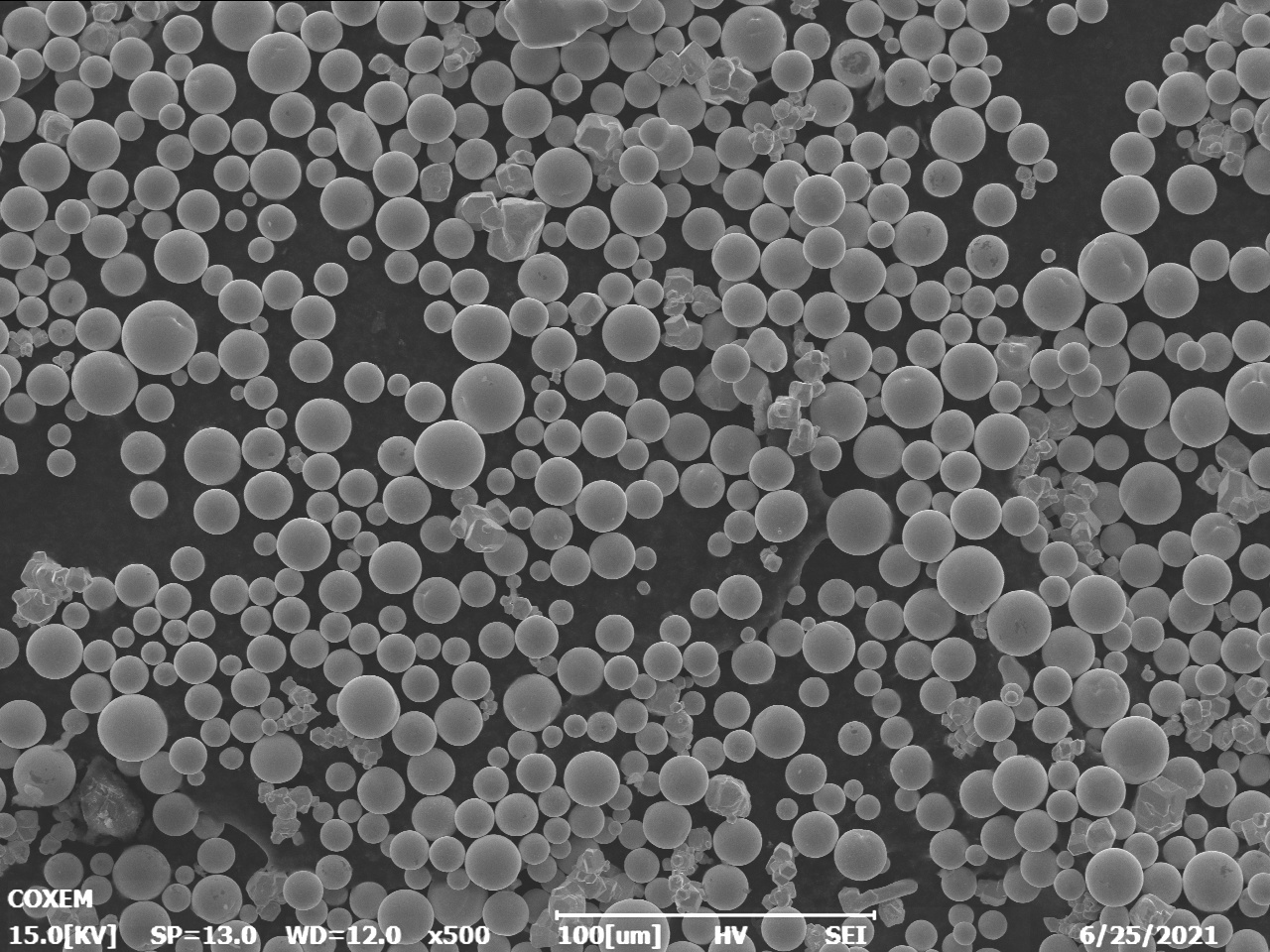

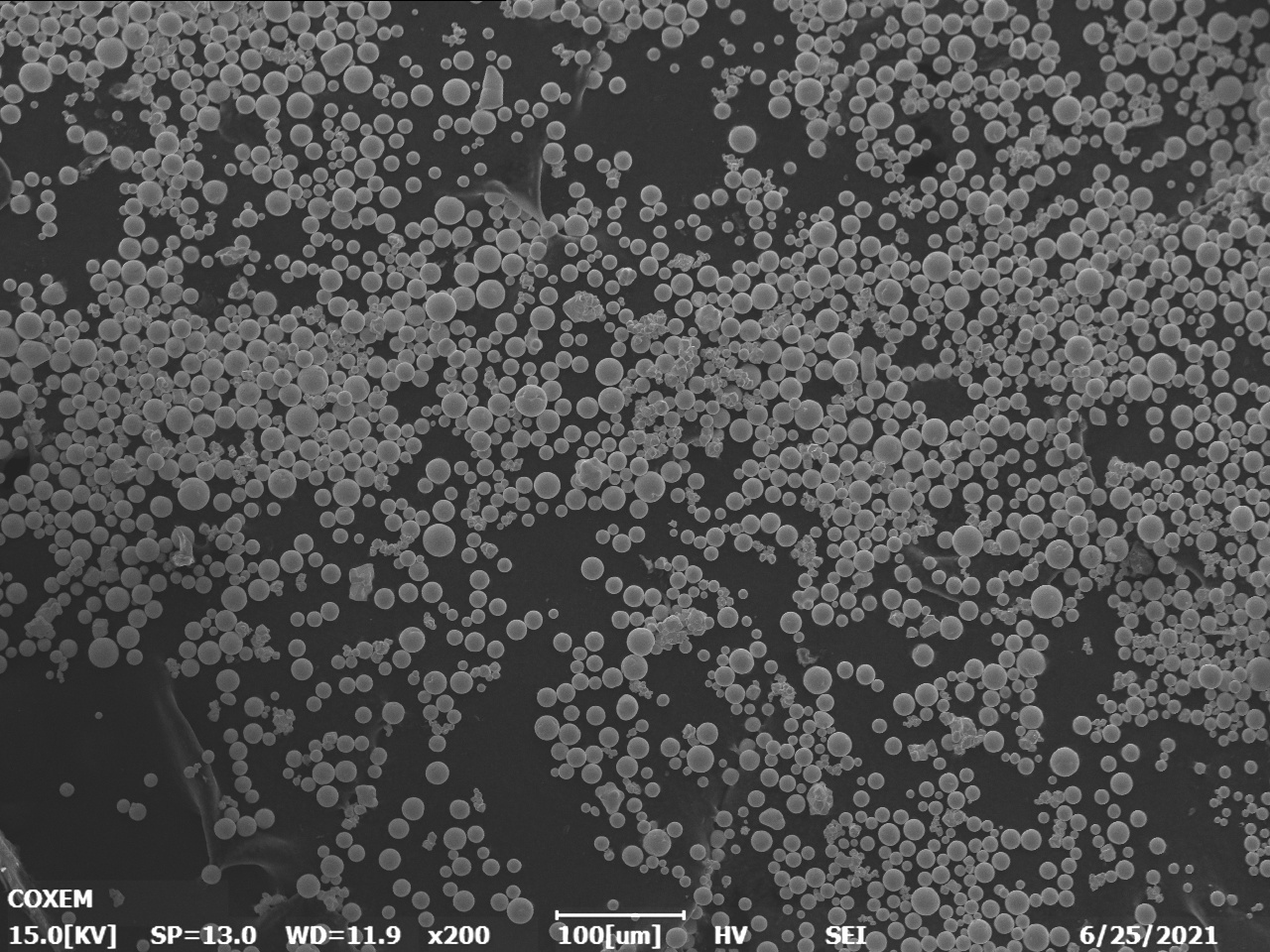

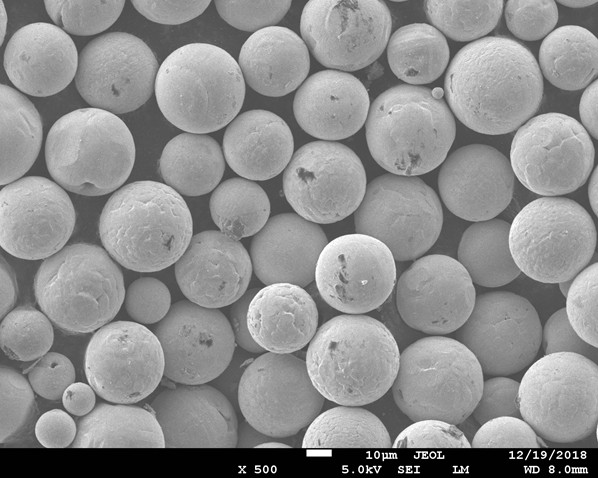

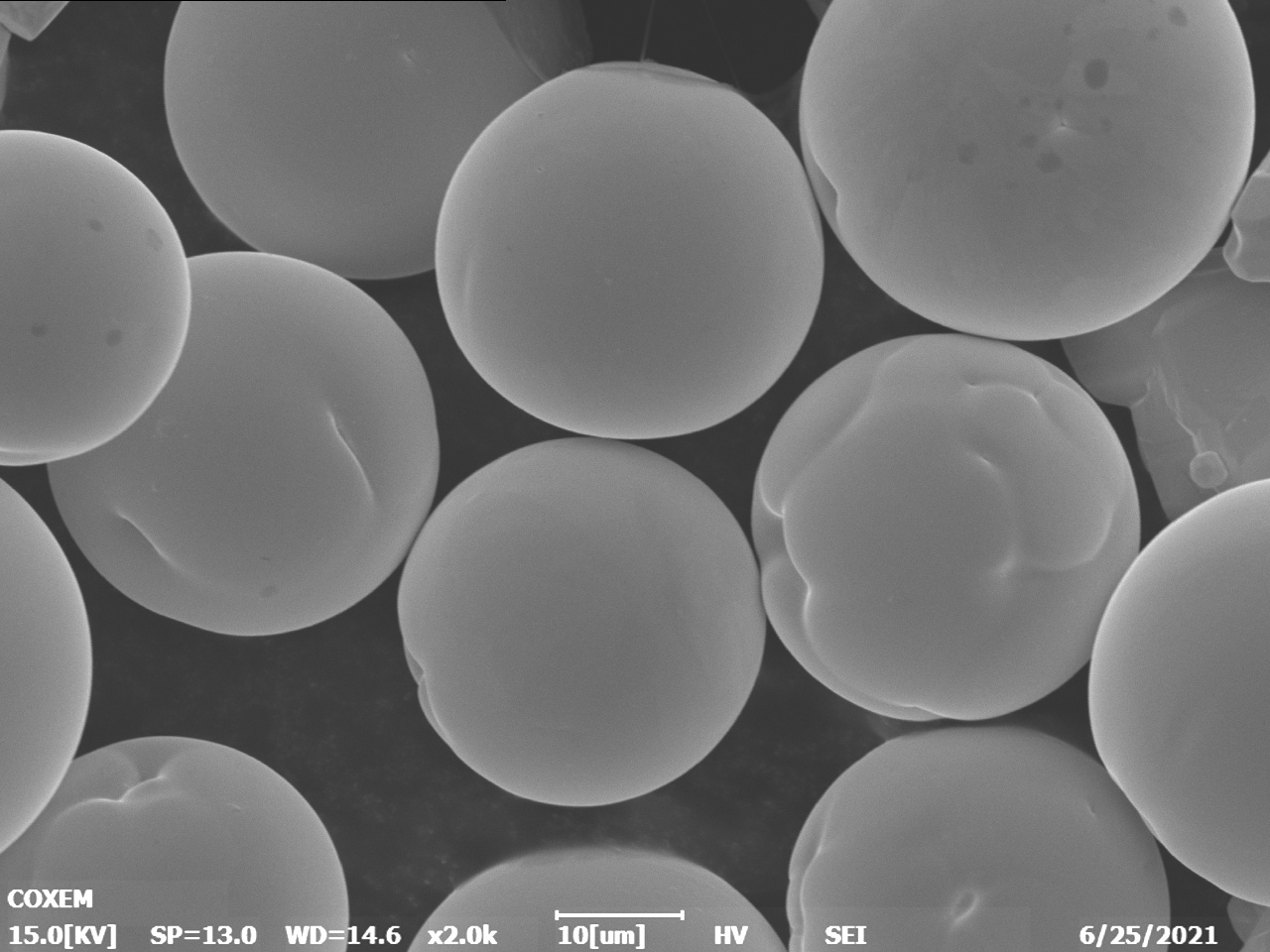

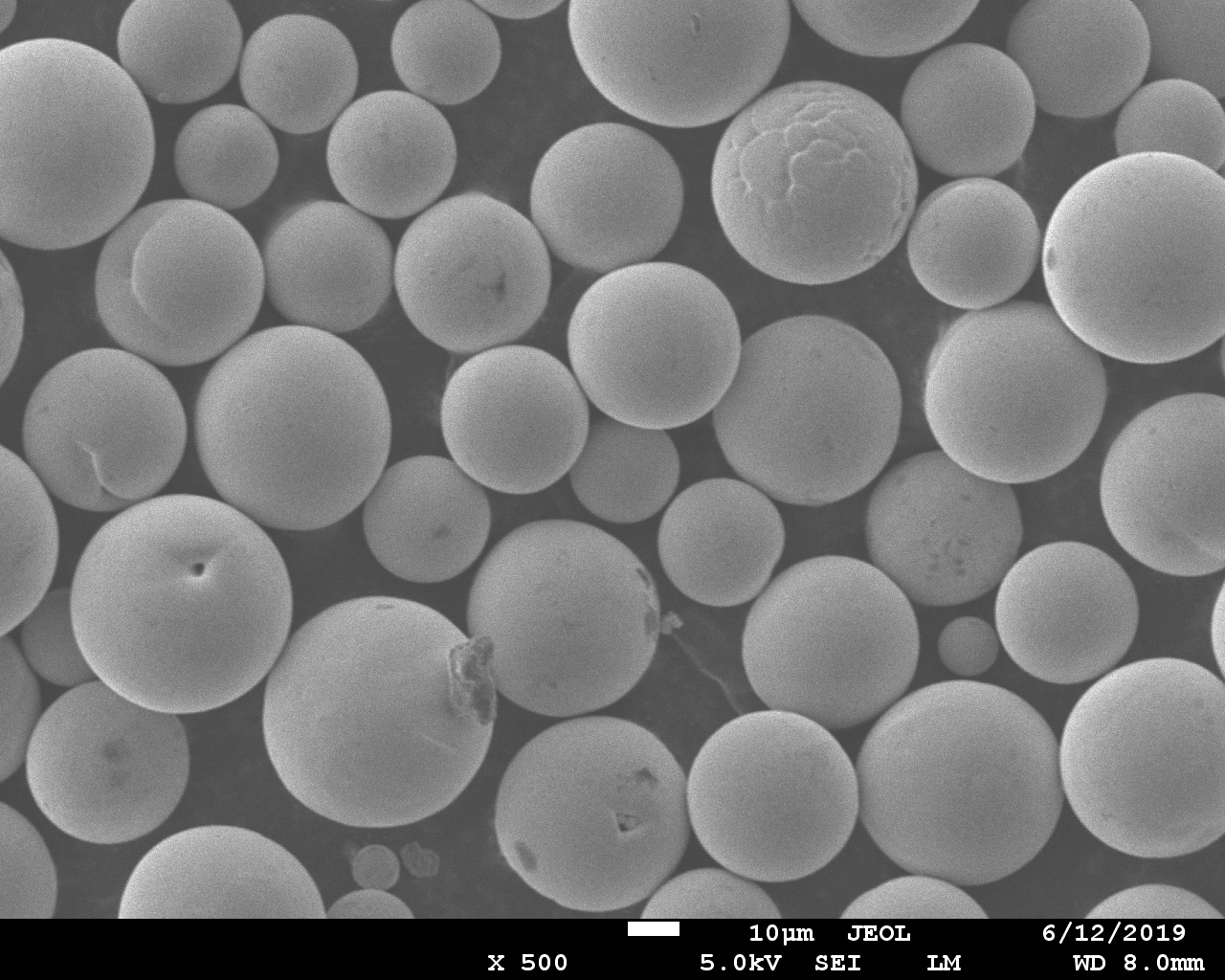

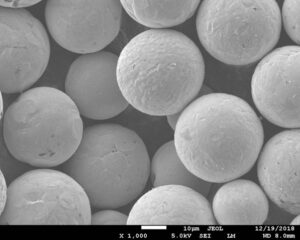

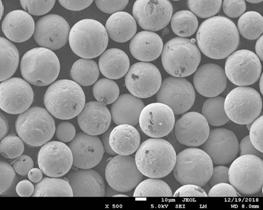

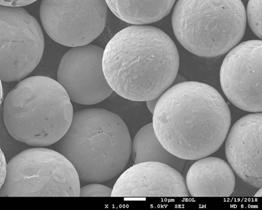

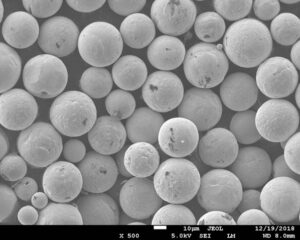

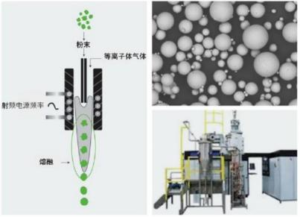

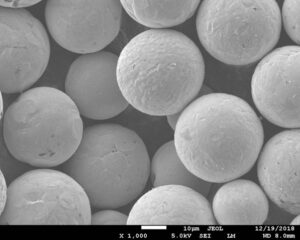

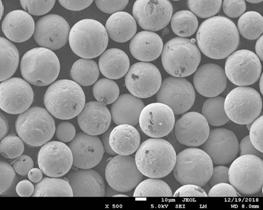

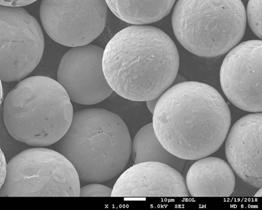

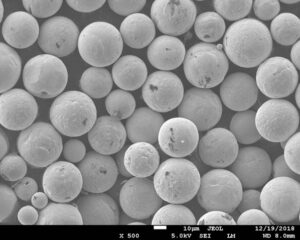

3.Images de la morphologie de la poudre au microscope électronique à balayage

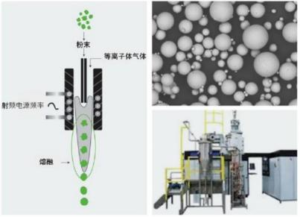

Photos de la production et des essais :

Photos de la production et des essais :

4.Application

4.Application

| Composition chimique (wt.%) | |||||||||

| Élément | W | T.C | F.C | Fe | Cr | V | Si | Mo+Co+Ni | O |

| Standard | ≥95 | 3.7~4.1 | ≤0.2 | ≤0.5 | ≤0.1 | ≤0.1 | ≤0.01 | ≤0.05 | ≤0.03 |

| typique | 95.31 | 4.01 | 0.163 | 0.168 | 0.0085 | 0.0005 | 0.0033 | 0.027 | 0.026 |

| Spherical Cast Tungsten Carbide powder | 45~100μm Particle Size Distribution | Débit (sec. pour 50 g) | Densité apparente (g/cm3) | Densité (g/cm3) | ||

| D10 | D50 | D90 | ||||

| Typique | 48.2μm | 80.5μm | 100.3μm | 4.3 | 10.46 | 12.13 |

| Spherical Cast Tungsten Carbide powder | <45μm Particle Size Distribution | Débit (sec. pour 50 g) | Densité apparente (g/cm3) | HV0.1 ( kg/mm2) | ||

| D10 | D50 | D90 | ||||

| Typique | 27.56μm | 34.50μm | 43.8μm | 6.99 | 9.35 | 2710 |

Photos de la production et des essais :

Photos de la production et des essais :

4.Application

4.Application

- The spherical cast tungsten carbide powder produced by our company has a high spheroidization rate (>95%), good sphericity, and excellent performance. It can be used in the production of plasma transfer arc welding (PTA), laser cladding, thermal spraying, etc.