球状金属粉 GH3230 高温合金粉

製品特性:...

GH3230 is a solid solution strengthened high-temperature alloy with W and Mo as the main strengthening elements. GH3230 alloy mainly improves its oxidation resistance by adding Cr element to the alloy, while adding trace elements to assist in improving the alloy’s oxidation resistance. Therefore, the alloy has good strength, thermal stability, and oxidation resistance. GH3230 alloy can be used to manufacture combustion chambers, flame tubes, heat exchangers, and other components of aviation turbine engines. It can also be used to manufacture combustion chamber components of ground gas turbines and high-temperature equipment components such as thermocouple protective sleeves and flame baffles for industrial furnaces.

| ブランド名 | ジンチュン |

| 起源 | 中国 |

| 商品名 | GH3230 powder |

| 申し込み | Thermocouple protective sleeves and flame baffles, etc. |

| 形状 | パウダー |

| カラー | Metal balck |

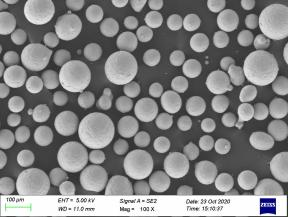

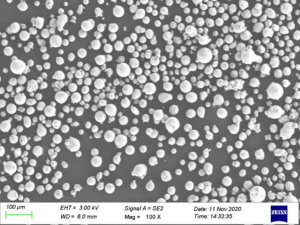

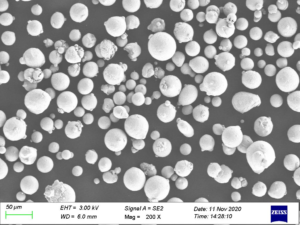

| サイズ | 15~53μm |

| スタンダード | GB/T 19001-2016/ISO9001: 2015 |

| 純度 | Ni: Bal%, Cr:20-24%, W:13-15%, Mo: 1-3%. |

| 素材 | Ni, Cr, W, Mo |

| 梱包 | 真空包装 |

製品詳細

製品詳細

製品キャラクター

GH3230 is a solid solution strengthened high-temperature alloy with W and Mo as the main strengthening elements. GH3230 alloy mainly improves its oxidation resistance by adding Cr element to the alloy, while adding trace elements to assist in improving the alloy’s oxidation resistance. Therefore, the alloy has good strength, thermal stability, and oxidation resistance. GH3230 alloy can be used to manufacture combustion chambers, flame tubes, heat exchangers, and other components of aviation turbine engines. It can also be used to manufacture combustion chamber components of ground gas turbines and high-temperature equipment components such as thermocouple protective sleeves and flame baffles for industrial furnaces.

2.仕様

GH3230 powder

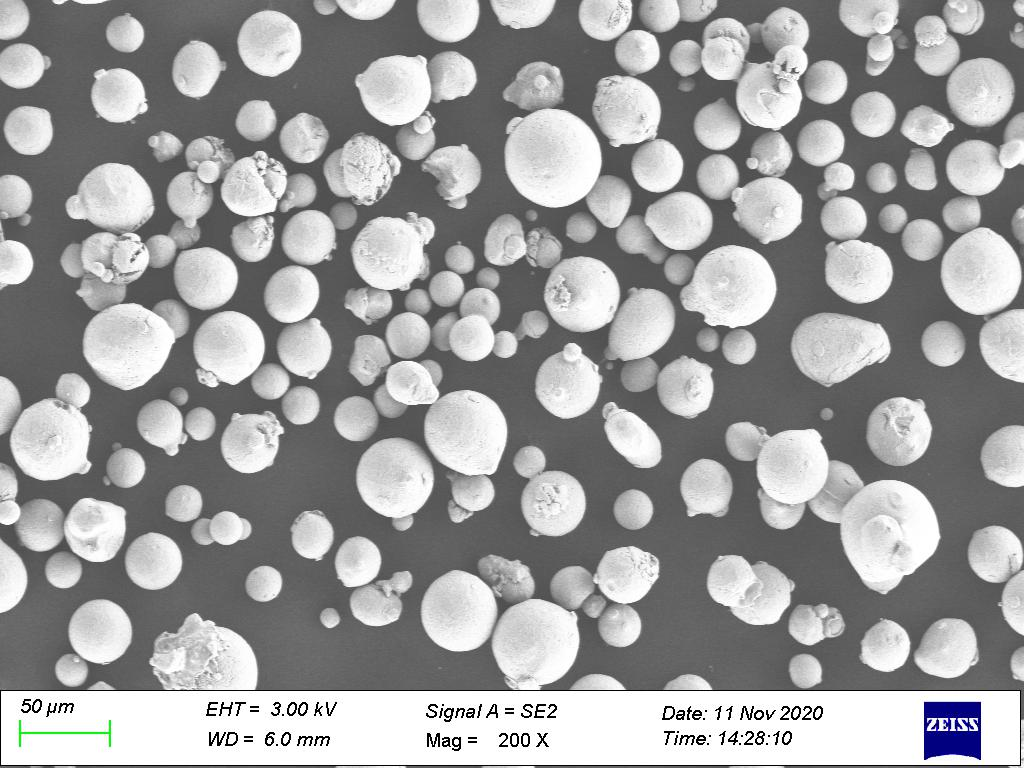

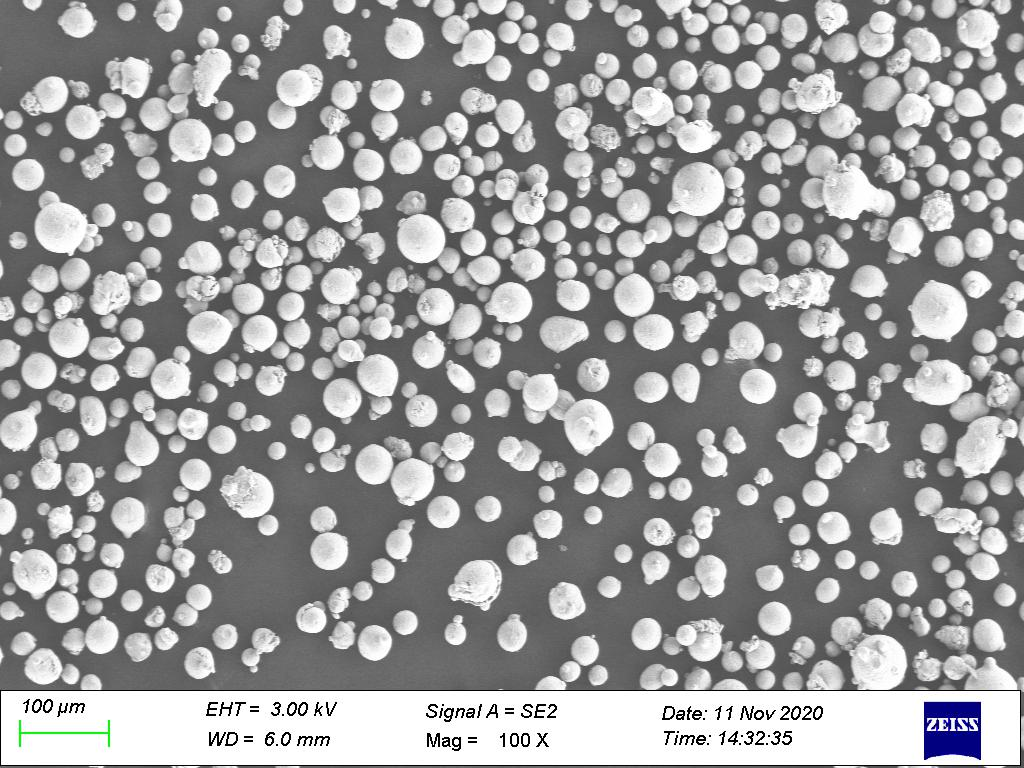

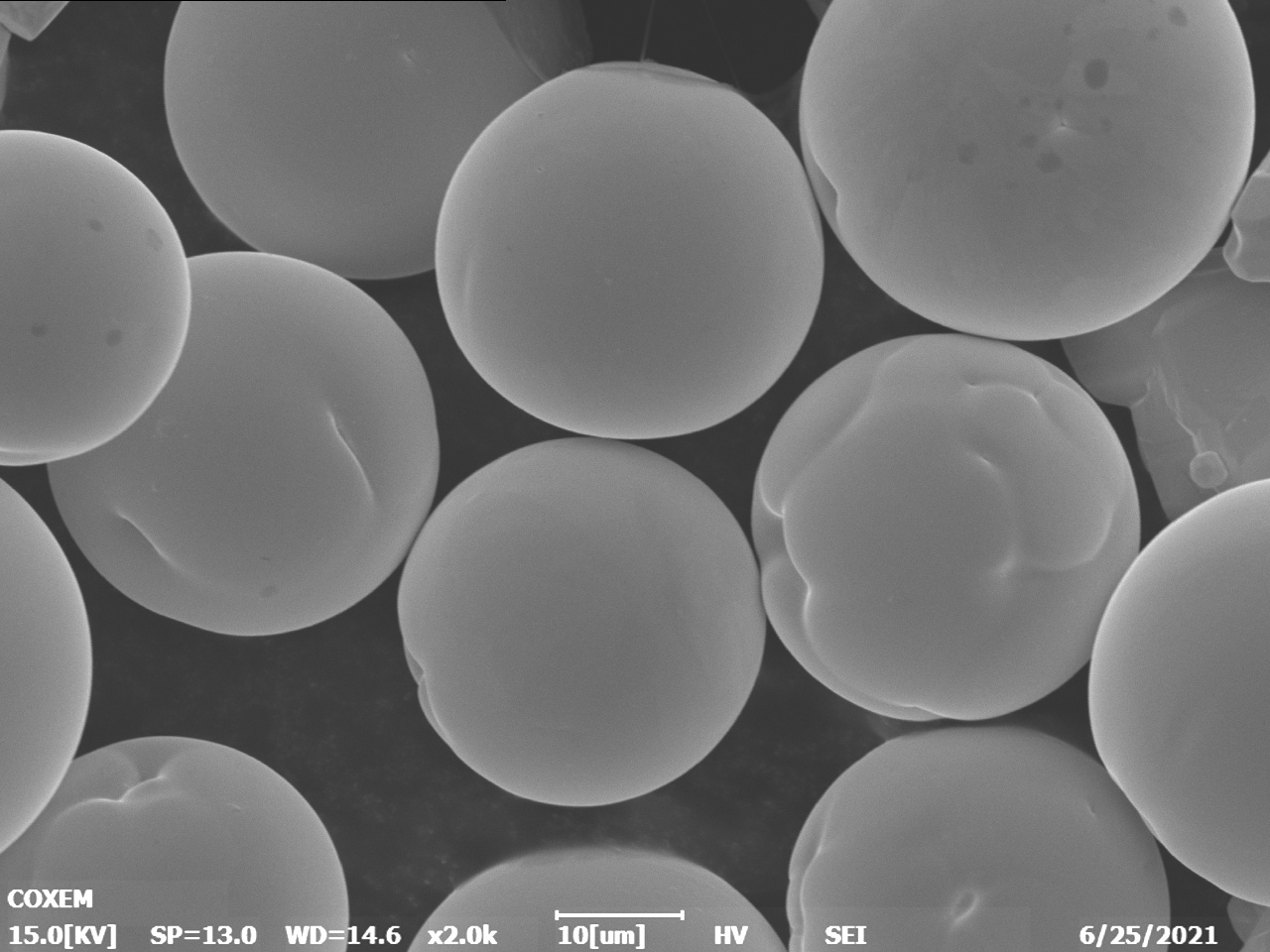

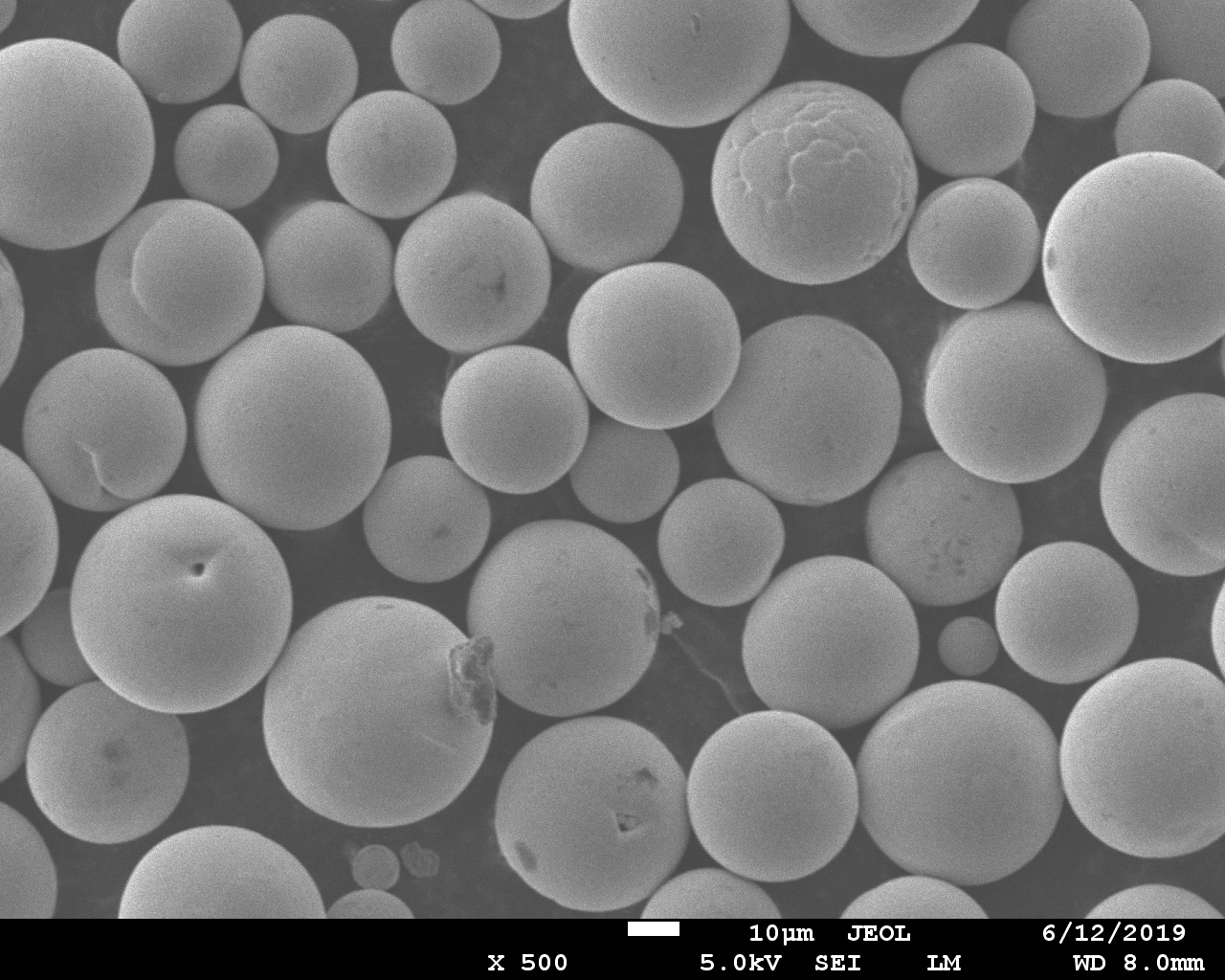

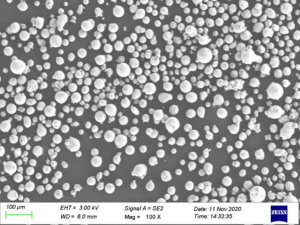

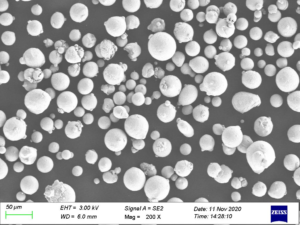

3.粉末のSEM形態写真

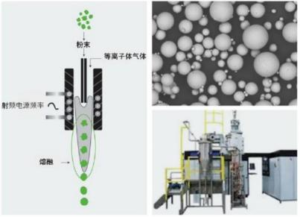

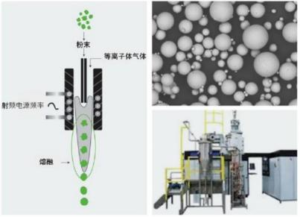

生産とテストの写真:

生産とテストの写真:

4.申し込み

4.申し込み

| 化学組成 (wt.%) | |||||||||

| エレメント | C | Cr | ニー | Co | モ | アル | ティ | フェ | B |

| スタンダード | 0.05~0.15 | 20.0~24.0 | バル | ≤5.0 | 1.0~3.0 | 0.2~0.5 | ≤0.10 | 1.5~2.0 | ≤0.015 |

| typical | 0.071 | 21.43 | バル | 2.01 | 2.02 | 0.33 | 0.06 | 1.76 | 0.0046 |

| エレメント | ムン | P | S | 銅 | W | Si | La | O | N |

| スタンダード | 0.3~1.0 | ≤0.02 | ≤0.003 | ≤0.50 | 13.0~15.0 | 0.25~0.45 | 0.005~0.05 | ≤0.030 | ≤0.030 |

| typical | 0.46 | 0.01 | 0.001 | 0.015 | 14.0 | 0.34 | 0.032 | 0.0092 | 0.002 |

| GH3230 | 15~53μm 粒度分布 | 流量 秒(50gの場合) | 見掛け密度(g/cm3) | タップ密度(g/cm3) | ||

| D10 | D50 | D90 | ||||

| スタンダード | 15~25 | 30~40 | 50~60 | ≤25 | ≥4.2 | ≥4.9 |

| typical | 23μm | 35.8μm | 53.5μm | 15.2 | 4.62 | 5.33 |

生産とテストの写真:

生産とテストの写真:

4.申し込み

4.申し込み

- GH3230 alloy can be used to manufacture combustion chambers, flame tubes, heat exchangers, and other components of aviation turbine engines. It can also be used to manufacture combustion chamber components of ground gas turbines and high-temperature equipment components such as thermocouple protective sleeves and flame baffles for industrial furnaces.