Os pós metálicos são adequados para processos de sinterização a alta temperatura?

What Are Metal Powders and How Are They Used in Sintering?

Metal powders are fine particles of metals that are commonly used in various manufacturing processes, including high-temperature sintering. Sintering is a technique where powdered materials are heated below their melting point to bond particles together, creating a solid piece. Jinchun, a leading metal powder manufacturer, provides high-quality metal powders specifically designed to meet the demands of high-temperature sintering processes.

Types of Metal Powders

Jinchun produces a wide range of metal powders, including iron, steel, aluminum, titanium, and nickel-based alloys. Each type of metal powder has unique properties that make it suitable for different applications. For high-temperature sintering, powders must have precise particle size distribution, high purity, and excellent thermal stability to ensure the final product meets the desired specifications.

Applications of Sintered Metal Parts

Sintered metal parts are used across various industries, including automotive, aerospace, medical, and electronics. These parts are valued for their strength, durability, and the ability to produce complex geometries that would be difficult or expensive to achieve through traditional manufacturing methods. Jinchun’s metal powders are engineered to deliver high performance in these critical applications.

Os pós metálicos são adequados para processos de sinterização a alta temperatura?

High-temperature sintering is a process that requires materials capable of withstanding extreme heat while maintaining their integrity and performance characteristics. The suitability of metal powders for this process depends on several factors, including the type of metal, particle size, and purity. Jinchun’s metal powders are specifically designed to meet these requirements, making them ideal for high-temperature sintering applications.

Thermal Stability and Melting Point

One of the primary considerations for high-temperature sintering is the melting point of the metal powder. Metals such as tungsten, molybdenum, and certain nickel-based alloys have very high melting points, making them suitable for sintering processes that involve extreme temperatures. Jinchun’s metal powders are carefully selected and processed to ensure they can withstand the high temperatures required for sintering without melting or degrading, resulting in strong and durable final products.

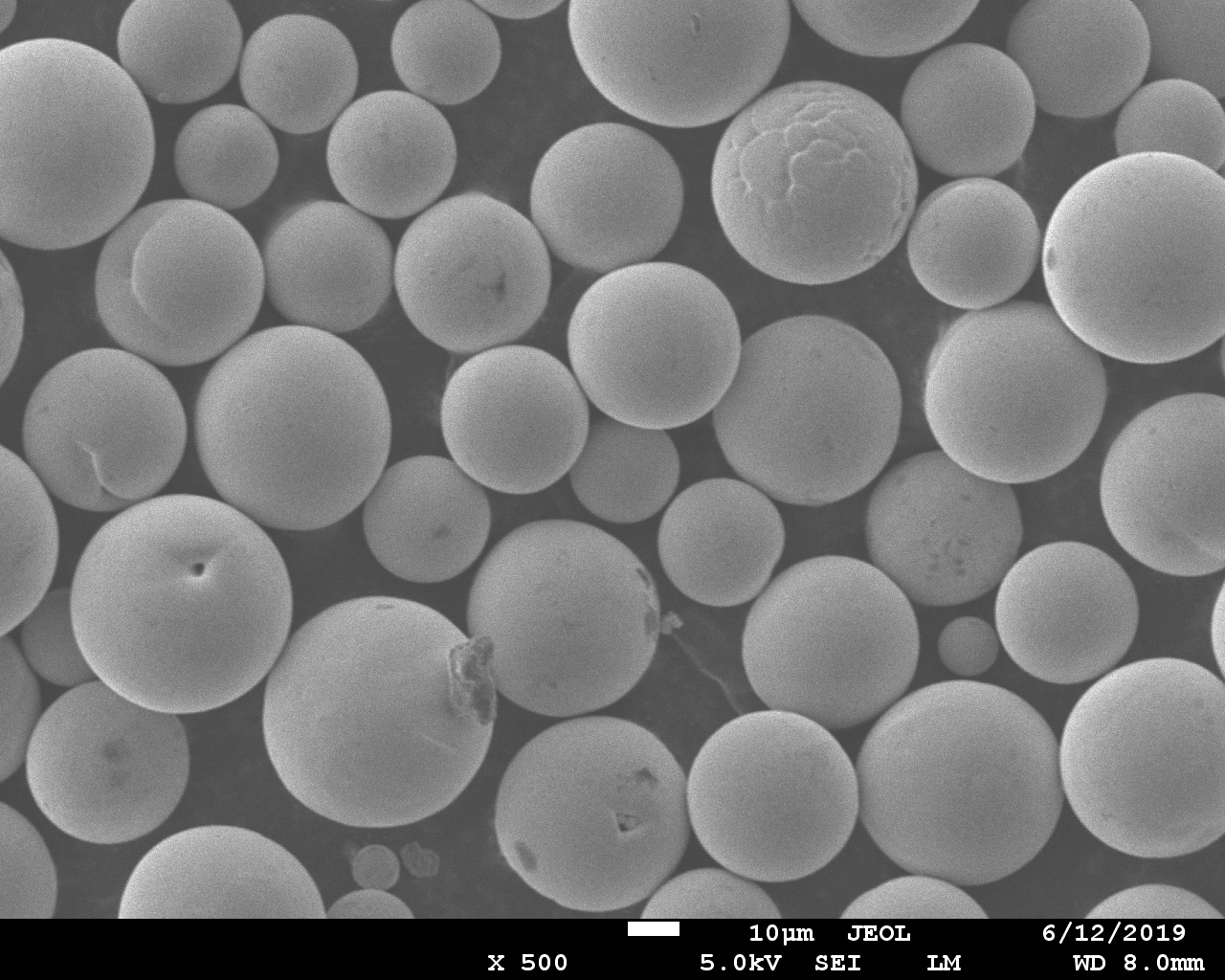

Particle Size and Distribution

The particle size and distribution of metal powders play a crucial role in the sintering process. Fine, uniformly sized particles provide better packing density, which enhances the sintering process and leads to stronger, more homogenous parts. Jinchun’s metal powders are produced with precise control over particle size distribution, ensuring optimal performance during high-temperature sintering. This results in parts with improved mechanical properties and consistent quality.

Purity and Contaminant Control

High purity is essential for metal powders used in sintering, especially at high temperatures, where impurities can cause defects or reduce the strength of the final product. Jinchun takes great care in ensuring that its metal powders are of the highest purity, with minimal contaminants. This attention to quality ensures that the sintering process produces parts that meet the stringent requirements of industries such as aerospace and medical devices, where reliability and performance are critical.

Why Choose Jinchun’s Metal Powders for High-Temperature Sintering?

Jinchun is a trusted name in the metal powder industry, known for producing high-quality powders that meet the demanding requirements of modern manufacturing processes. Here’s why Jinchun’s metal powders are the ideal choice for high-temperature sintering.

Advanced Manufacturing Techniques

Jinchun utilizes advanced manufacturing techniques to produce metal powders with precise particle size distribution, high purity, and excellent thermal stability. These powders are engineered to perform consistently in high-temperature environments, ensuring that the final sintered products meet or exceed industry standards.

Rigorous Quality Control

Quality control is a top priority at Jinchun. Each batch of metal powder undergoes rigorous testing to ensure it meets the specific requirements for high-temperature sintering. This includes tests for particle size distribution, purity, and thermal properties. By maintaining strict quality control, Jinchun ensures that its metal powders deliver reliable performance in every application.

Expertise and Support

With years of experience in the metal powder industry, Jinchun offers expert support to help customers choose the right powder for their specific sintering applications. Whether you need assistance with material selection, process optimization, or technical guidance, Jinchun’s team of experts is ready to assist you in achieving the best results.

Conclusão

Metal powders are highly suitable for high-temperature sintering processes, provided they are carefully selected and manufactured to meet the demands of the application. Jinchun’s metal powders are designed with the specific needs of high-temperature sintering in mind, offering superior thermal stability, purity, and particle size distribution. Whether you are producing parts for the aerospace, automotive, or medical industries, Jinchun’s metal powders provide the reliability and performance you need to succeed.

_6258副本-2.jpg)