Consumíveis de soldadura Materiais metálicos Preto Verde Pó de carboneto de silício

Carácter do produto:

Silicon carbide powders are widely used in various fields of abrasives and grinding tools due to their advantages such as wear resistance, high hardness, high temperature resistance, low expansion coefficient, and oxidation resistance.

| Nome da marca | Jinchun |

| Origem | China |

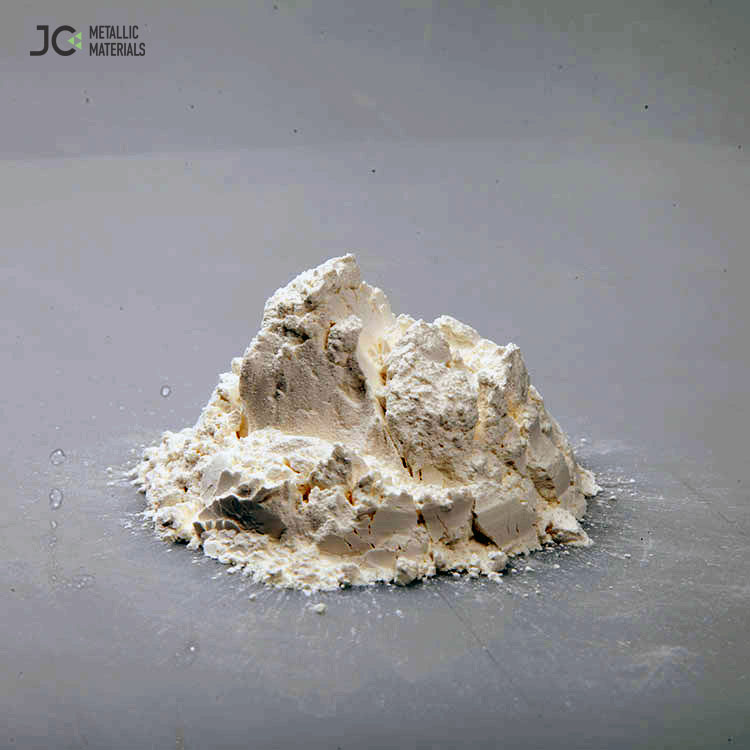

| Nome do produto | Black Silicon carbide powder, Green silicon carbide powder |

| Aplicação | Welding consumables, functional ceramics, advanced refractory materials, Metallurgical materials, Environmental protection industry, abrasive, Grinding and Polishing, Electronic products, Aerospace, etc. |

| Forma | Pó |

| Cor | Metal black, green |

| Tamanho | 4#-240#, 230#-8000#, W1.5-W63, 20mesh, 24mesh, 30 mesh, 36 mesh, 46 mesh, 60 mesh, 70 mesh, 80mesh, etc. |

| Padrão | GB/T 19001-2016/ISO9001: 2015 |

| Pureza | SiC 99.5% |

| Raw material | Silicon carbide |

| Embalagem | Ton bags |

DETALHE DO PRODUTO

DETALHE DO PRODUTO

Carácter do produto

Silicon carbide powders are widely used in various fields of abrasives and grinding tools due to their advantages such as wear resistance, high hardness, high temperature resistance, low expansion coefficient, and oxidation resistance.

2.Especificação

Silicon carbide powder

3.Application of Black silicon carbide powder

| Silicon carbide powder | Elemento | SiC | Fe2O3 | F. C |

| Resultado(%) | 99.51 | 0.144 | 0.17 |

- Functional ceramics

- Advanced refractory materials

- Sandblasting

- Metallurgical materials

- Consumíveis de soldadura

- Environmental Protection Industry

- Abrasive: Green silicon carbide is commonly used in the manufacture of grinding wheels, sandpapers, and cutting tools, particularly suitable for applications that require precision and high-quality surface treatment.

- Grinding and Polishing: The fragility of green silicon carbide makes it a popular choice for grinding and polishing operations, including polishing gemstones, glass, and semiconductor materials.

- Advanced ceramics: Due to its high purity, green silicon carbide is often used as an additive in advanced ceramic production to improve its mechanical properties and wear resistance.

- Electronic products: The semiconductor properties of green silicon carbide make it suitable for use in the field of power electronics, such as high-voltage power transistors and light-emitting diodes (LEDs).

- Aerospace: Lightweight materials, high strength, and excellent thermal performance make it an attractive choice for aerospace components such as engine parts and heat shields.

- Welding Consumables.