Carbonyl lron Powder Magnetic Material Raw Powder Series

Product Character:

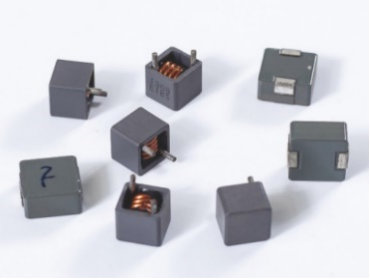

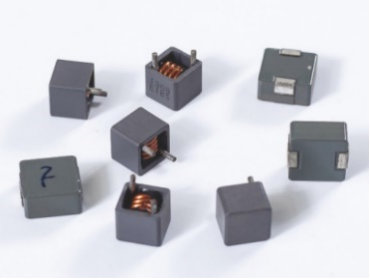

The carbonyl iron powder magnetic material raw powder series is suitable for various high-frequency magnetic rings, high current molded inductors (SMD) high-frequency magnetic rings, injection molded inductors, etc. through different particle size combinations.

| Brand Name | Jinchun |

| Origin | China |

| Product name | Carbonyl iron powder magnetic materials raw powder series |

| Application | Electronic product, inductance, etc. |

| Shape | Powder |

| Color | Metal black |

| Size | D50: 3.0-4.5um, 2.0-4.0m, 1.5-2.2um, 2.5-3.5um, 4.0-5.0um, etc. |

| Standard | GB/T 19001-2016/ISO9001: 2015 |

| Purity | Fe: 97.5%. |

| Material | Fe |

| Packing | Steel drums |

PRODUCT DETAIL

PRODUCT DETAIL

Product Character

The carbonyl iron powder magnetic material raw powder series is suitable for various high-frequency magnetic rings, high current molded inductors (SMD) high-frequency magnetic rings, injection molded inductors, etc. through different particle size combinations.

2.Specification

Carbonyl lron Powder Magnetic Material Raw Powder Series

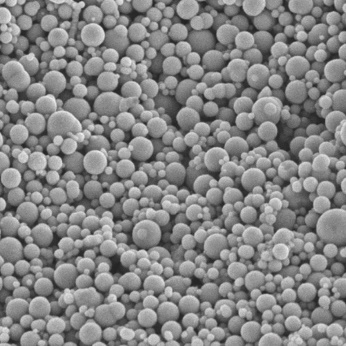

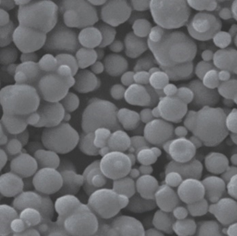

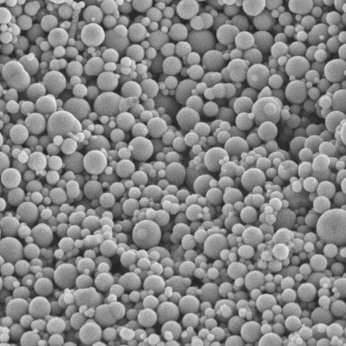

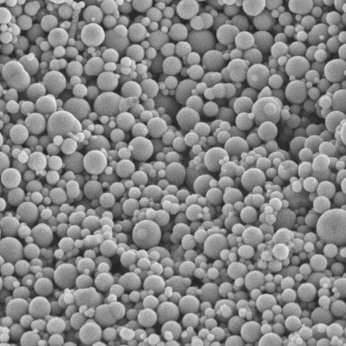

3.Pictures of Powder SEM morphology

4.Application

4.Application

| Marks | Chemical Composition | Physical Property | Remark | |||||||

| Particle size(μm) | Ddensity (g/cm³) | |||||||||

| D10 | D50 | D90 | Loose Density | Tap Density | ||||||

| XJC-B1 | Fe | C | O | N | 1.5-2.5 | 3.0-4.5 | 6.0-8.0 | 2.0-3.0 | 3.5-4.5 | |

| ≥97.5 | ≤0.8 | ≤0.4 | ≤0.6 | |||||||

| XJC-B2 | Fe | C | O | N | 1.0-2.0 | 2.0-4.0 | 5.0-7.0 | 2.0-3.0 | 3.5-4.5 | |

| ≥97.5 | ≤0.8 | ≤0.4 | ≤0.6 | |||||||

| XJC-B3 | Fe | C | O | N | 1.0-1.2 | 1.5-2.2 | 2.5-3.5 | 2.0-3.0 | 3.5-4.5 | |

| ≥97.5 | ≤0.8 | ≤0.4 | ≤0.6 | |||||||

| XJC-B4 | Fe | C | O | N | 1.5-2.5 | 2.5-3.5 | 5.0-6.5 | 2.0-3.0 | 3.5-4.5 | |

| ≥97.5 | ≤0.8 | ≤0.4 | ≤0.6 | |||||||

| XJC | Fe | C | O | N | 1.8-3.5 | 4.0-5.0 | 8.5-13.0 | 2.0-3.0 | 3.5-4.5 | |

| Bal | ≤0.02 | ≤0.3 | ≤0.03 | |||||||

| Test equipment | 1.Laser Particle SizeTester 2.Loose density and compacted de nsity 3.0xygen and Nitrogen Tester,Carbon and Sulfur Tester | |||||||||

| Magnetic property Test Conditions | Magnetic ring size | Out diameter:10.73, inner diameter:6,height:3 | Magnetic ring density | 6.0-6.5 |

| Coil) | Diameter:0.3, number of turns:20 turns | Test frequenoy | 100KHz/1V | |

| Molding powder loading amount | 1g±0.05 | Voltage withstand test | 100V/35 | |

| Test equipment | 1.Digital bridge 2.Insulation impedance | |||

4.Application

4.Application