Spherical Metal Powders GH3625 Superalloy High-temperature alloy Powder

Product Character:

GH3625 high-temperature alloy belongs to solid solution strengthening alloys with added elements such as Nb, Mo, Cr, etc., and has high strength, excellent corrosion resistance and oxidation resistance, and resistance to stress corrosion under salt spray atmosphere applied in the manufacturing of aviation engine components, aerospace structural components, and chemical equipment components.

| Brand Name | Jinchun |

| Origin | China |

| Product name | GH3625 powder |

| Application | Aviation engine components, aerospace structural components, and chemical equipment components. |

| Shape | Powder |

| Color | Metal gray |

| Size | 15~53μm |

| Standard | GB/T 19001-2016/ISO9001: 2015 |

| Purity | Ni: Bal. Cr: 20.0-23.0%, Mo:8.0-10.0%, Nb: 3.15-4.15% |

| Material | Ni, Cr, Mo, Nb |

| Packing | Vacuum packing |

PRODUCT DETAIL

PRODUCT DETAIL

Product Character

GH3625 high-temperature alloy belongs to solid solution strengthening alloys with added elements such as Nb, Mo, Cr, etc., and has high strength, excellent corrosion resistance and oxidation resistance, and resistance to stress corrosion under salt spray atmosphere applied in the manufacturing of aviation engine components, aerospace structural components, and chemical equipment components.

2.Specification

GH3625 powder

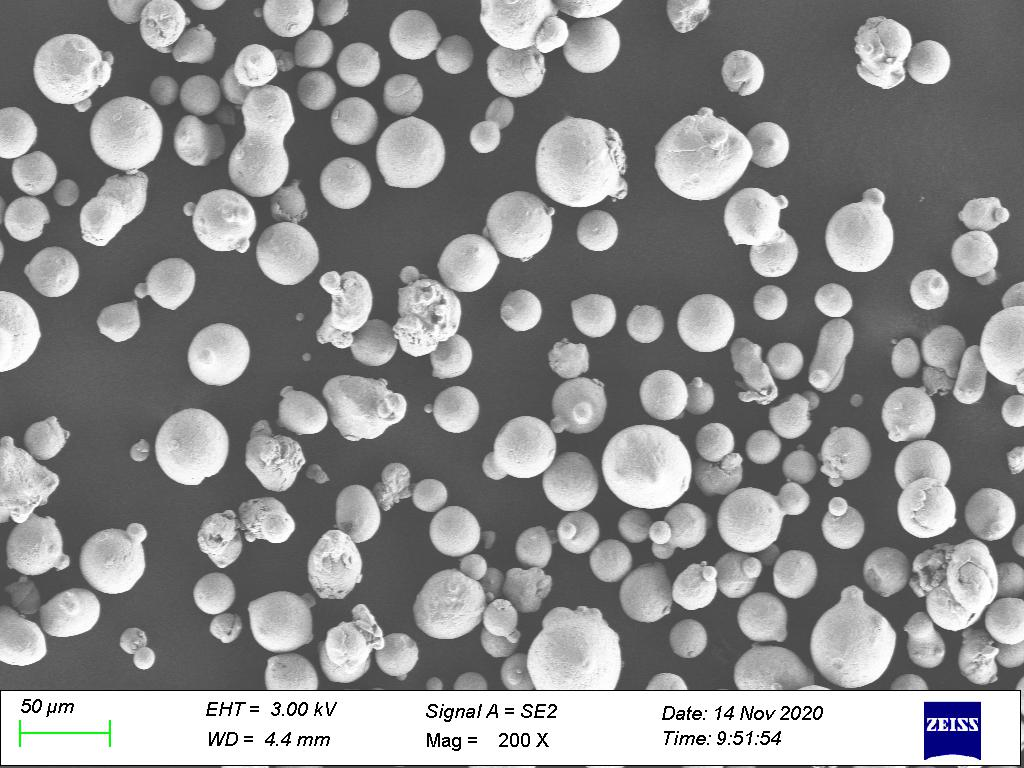

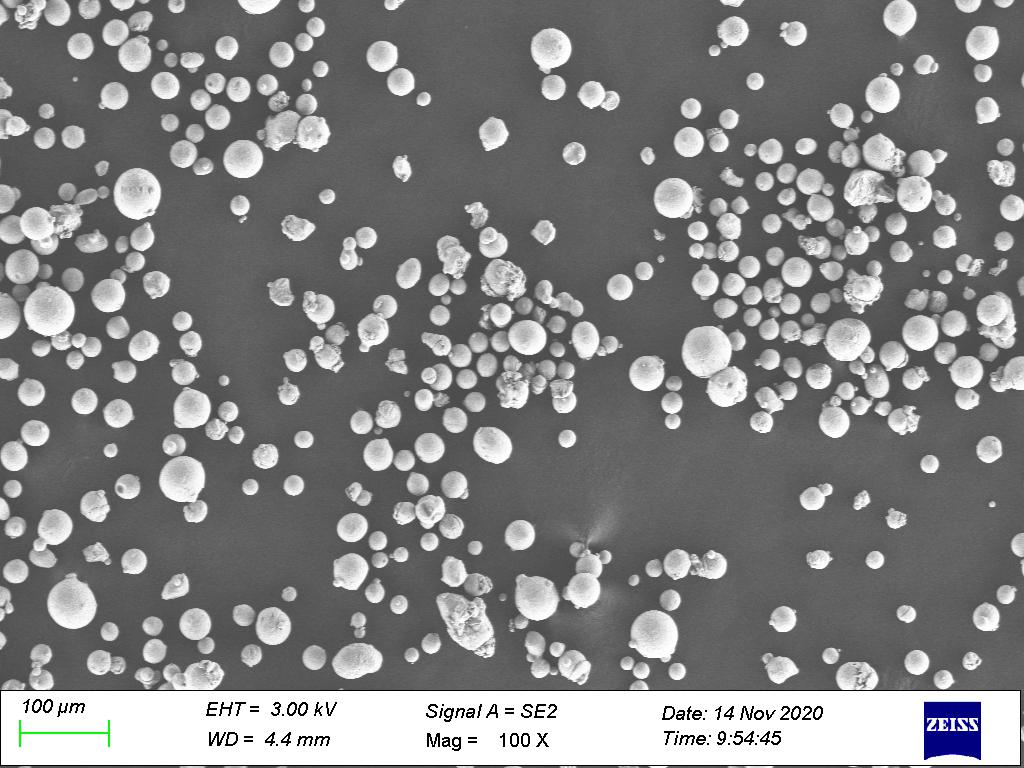

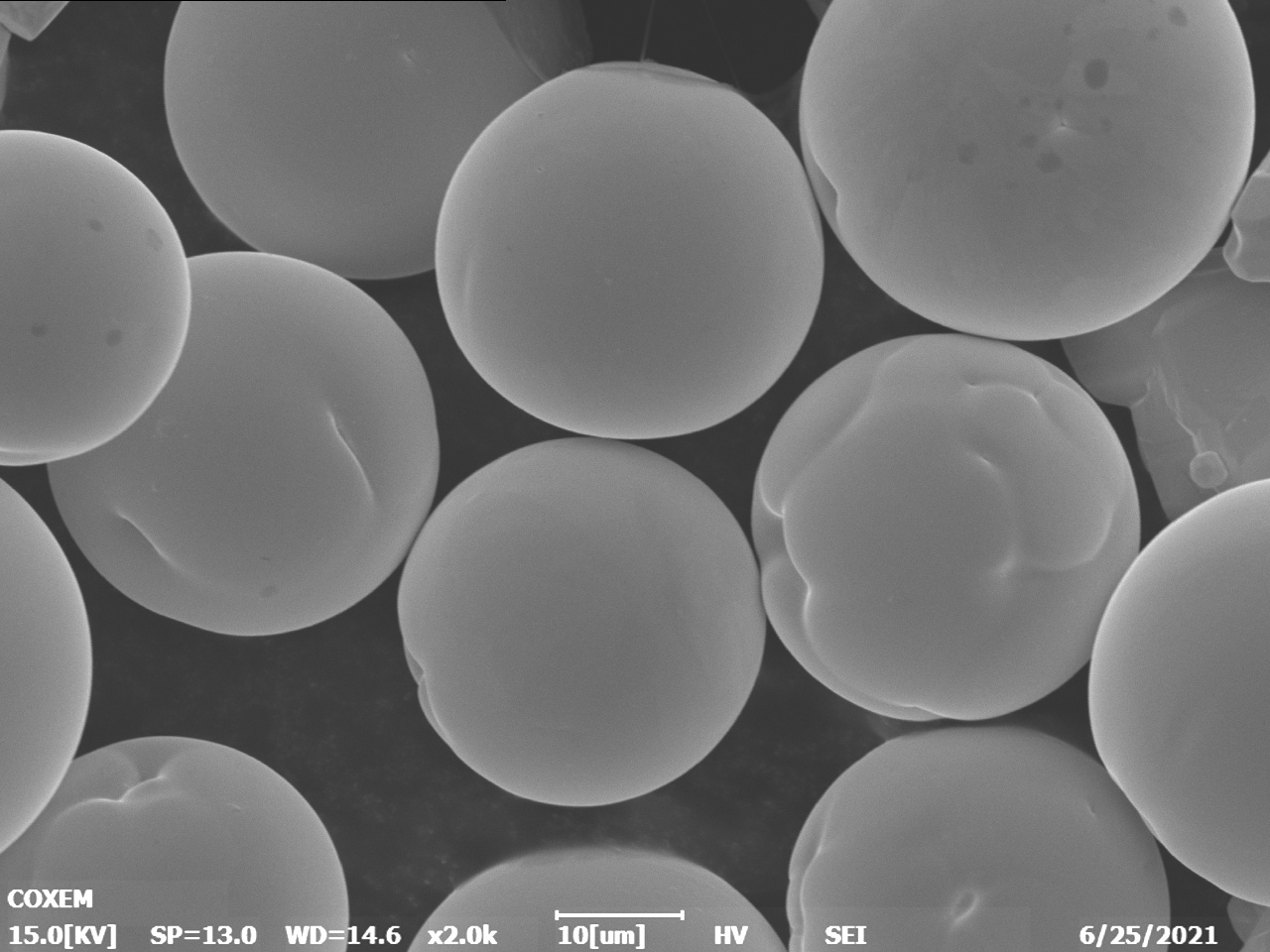

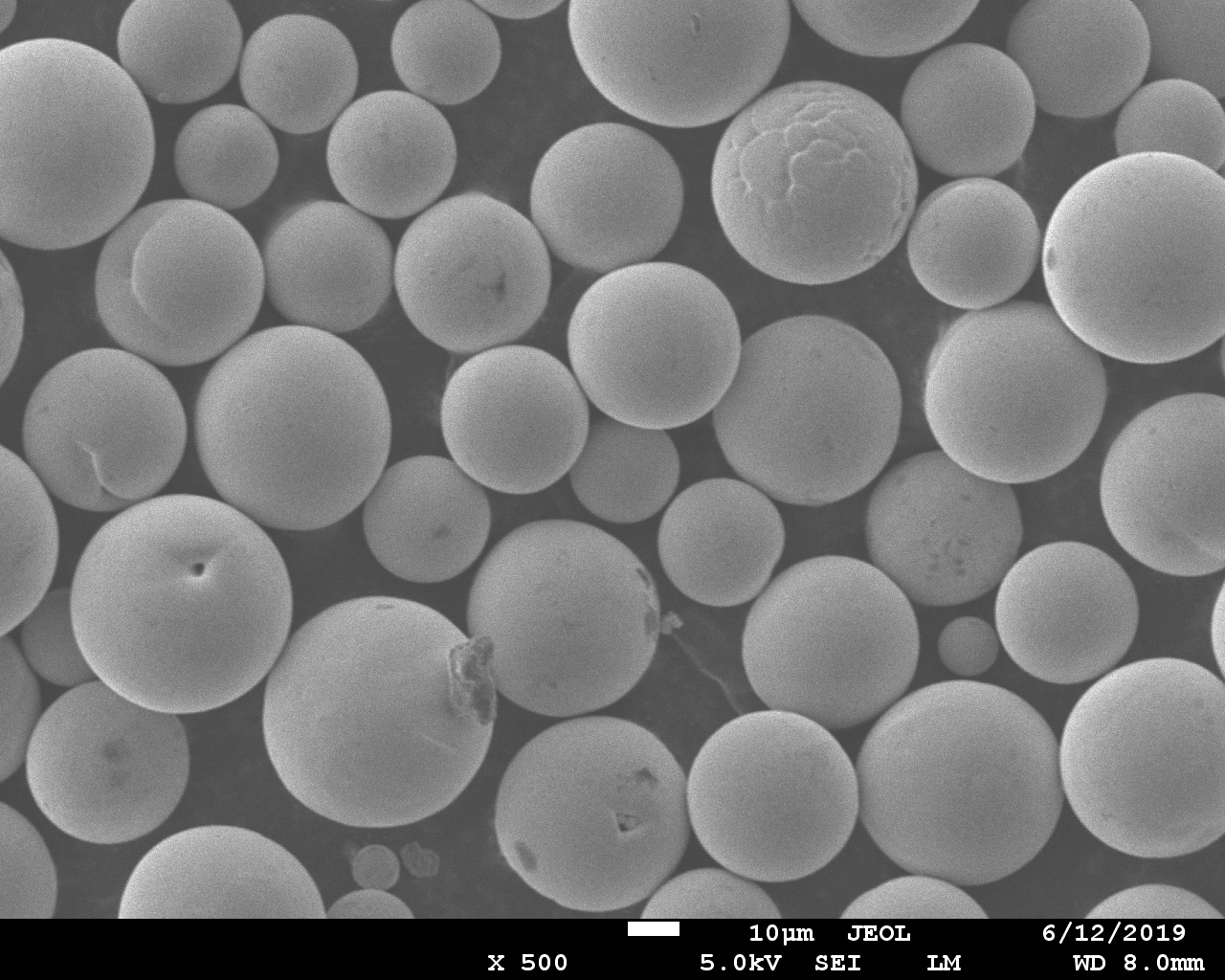

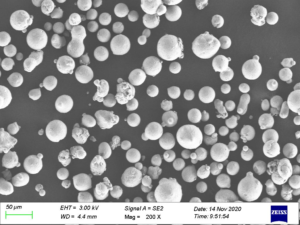

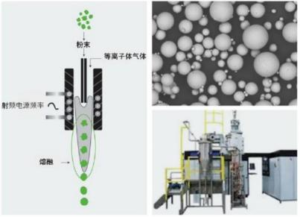

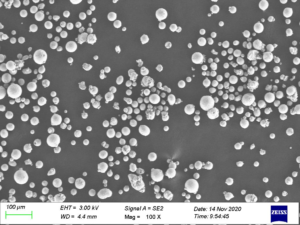

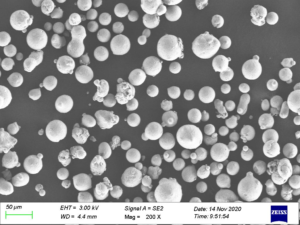

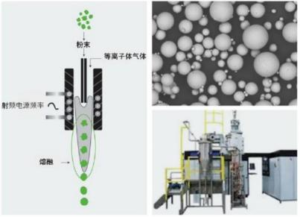

3.Pictures of Powder SEM morphology

Pictures of Production and Test:

Pictures of Production and Test:

4.Application

4.Application

| Chemical Composition (wt.%) | ||||||||

| Element | C | Cr | Ni | Co | Mo | Al | Ti | Fe |

| Standard | ≤0.10 | 20.0~23.0 | Bal. | ≤1.0 | 8.0~10.0 | ≤0.40 | ≤0.40 | ≤5.0 |

| typical | 0.0048 | 22.42 | Bal. | 0.006 | 9.12 | 0.13 | 0.018 | 0.72 |

| Element | Mn | P | S | Cu | Nb | Si | O | N |

| Standard | ≤0.50 | ≤0.015 | ≤0.015 | ≤0.070 | 3.15~4.15 | ≤0.50 | ≤0.030 | ≤0.030 |

| typical | 0.031 | 0.007 | 0.0014 | 0.011 | 3.75 | 0.025 | 0.014 | 0.013 |

| GH3625 | 15~53μm Particle Size Distribution | Flow Rate (sec. for 50 g) | Apparent density (g/cm3) | Tap density (g/cm3) | ||

| D10 | D50 | D90 | ||||

| Standard | 15~25 | 30~40 | 50~60 | ≤25 | ≥4.2 | ≥4.9 |

| typical | 23.4μm | 36.2μm | 55.2μm | 20 | 4.24 | 5.03 |

Pictures of Production and Test:

Pictures of Production and Test:

4.Application

4.Application

- GH3625 powder is applied in the manufacturing of aviation engine components, aerospace structural components, and chemical equipment components.