Welding Consumables Metal Materials reduced iron powder FHT40.30, FHT40.37, FHT100.25

Product Character:The reduction process is divided into (solid carbon reduction) primary reduction and secondary reduction. The primary reduction is the production of sponge iron by solid carbon reduction. The main process of primary reduction is: (iron concentrate, rolled steel scales, etc.) → drying → magnetic separation → crushing → screening → canning → entering the primary reduction furnace → sponge iron. Secondary precision reduction process: Sponge iron → Cleaning → Crushing → Magnetic separation → Secondary reduction furnace → Powder block → Crushing → Magnetic separation → Screening → Grading → Mixing → Packaging → Finished product.

| Brand Name | Jinchun |

| Origin | China |

| Product name | Reduced iron powder FHT40.30, FHT40.37, FHT100.25 |

| Application | Powder metallurgy products, welding electrodes, flame cutting etc. |

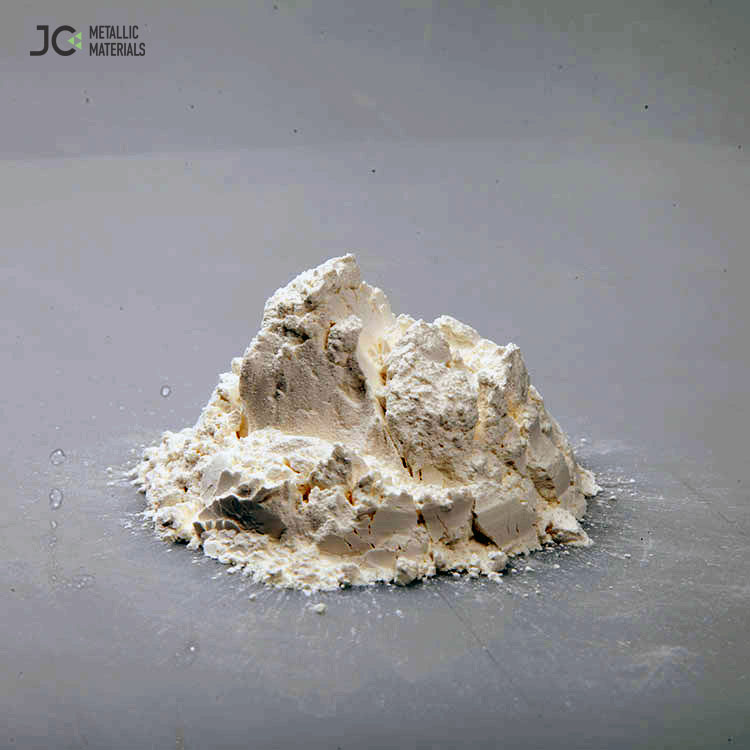

| Shape | Powder |

| Color | Metal gray balck |

| Size | 40mesh , 100 mesh |

| Standard | GB/T 19001-2016/ISO9001: 2015 |

| Purity | 98.5% min |

| Material | Iron oxide |

| Packing | Ton bags |

PRODUCT DETAIL

PRODUCT DETAIL

Product Character

The reduction process is divided into (solid carbon reduction) primary reduction and secondary reduction. The primary reduction is the production of sponge iron by solid carbon reduction. The main process of primary reduction is: (iron concentrate, rolled steel scales, etc.) → drying → magnetic separation → crushing → screening → canning → entering the primary reduction furnace → sponge iron. Secondary precision reduction process: Sponge iron → Cleaning → Crushing → Magnetic separation → Secondary reduction furnace → Powder block → Crushing → Magnetic separation → Screening → Grading → Mixing → Packaging → Finished product.

1.Specification

Reduced iron powder FHT40.30, FHT40.37, FHT100.25

2.Pictures of Raw Materials and Production

Pictures of Production:

3.Application

3.Application

| Name/ Type | Element | Fe | C | Si | Mn | P | S | H Loss |

| Reduced iron powder | Standard(%) | >98.5 | <0.03 | <0.10 | <0.30 | <0.030 | <0.030 | <0.030 |

| Result(%) | 98.70 | 0.013 | 0.08 | 0.08 | 0.010 | 0.016 | 0.25 |

3.Application

3.Application

High strength structural components in powder metallurgy, pharmaceutical and chemical industries, chemical catalysts, hard alloys, diamond tools, soft magnetic powder parts, rubber resin products, welding materials, metal smelting, environmental protection industry, daily necessities industry, food industry and other industries.