Diamond Tools Metal Materials Spherical Metal Powders Nickel Powder

Product Character:

The applications of spherical nickel powder include metal 3D printing, laser cladding, surface spraying, diamond tools, battery cathode materials, conductive coatings, etc.

| Brand Name | Jinchun |

| Origin | China |

| Product name | Spherical Nickel powder |

| Application | 3D printing, additiva manufacturing, Laser cladding, diamond tools, spraying and coating, etc. |

| Shape | Powder |

| Color | Metal gray brown |

| Size | 15~45μm, 45~106μm, or customized. |

| Standard | GB/T 19001-2016/ISO9001: 2015 |

| Purity | Ni: 99.7% min |

| Material | Nickel |

| Packing | Vacuum packing |

PRODUCT DETAIL

PRODUCT DETAIL

Product Character

The applications of spherical nickel powder include metal 3D printing, laser cladding, surface spraying, diamond tools, battery cathode materials, conductive coatings, etc.

2.Specification

Spherical Nickel Powder

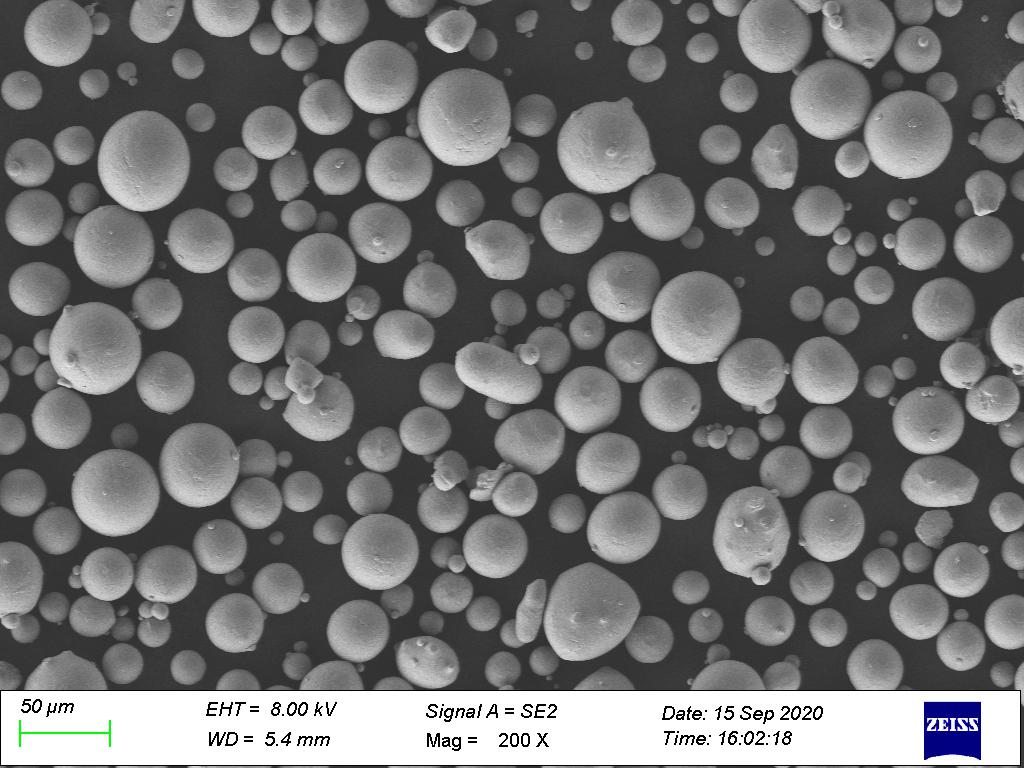

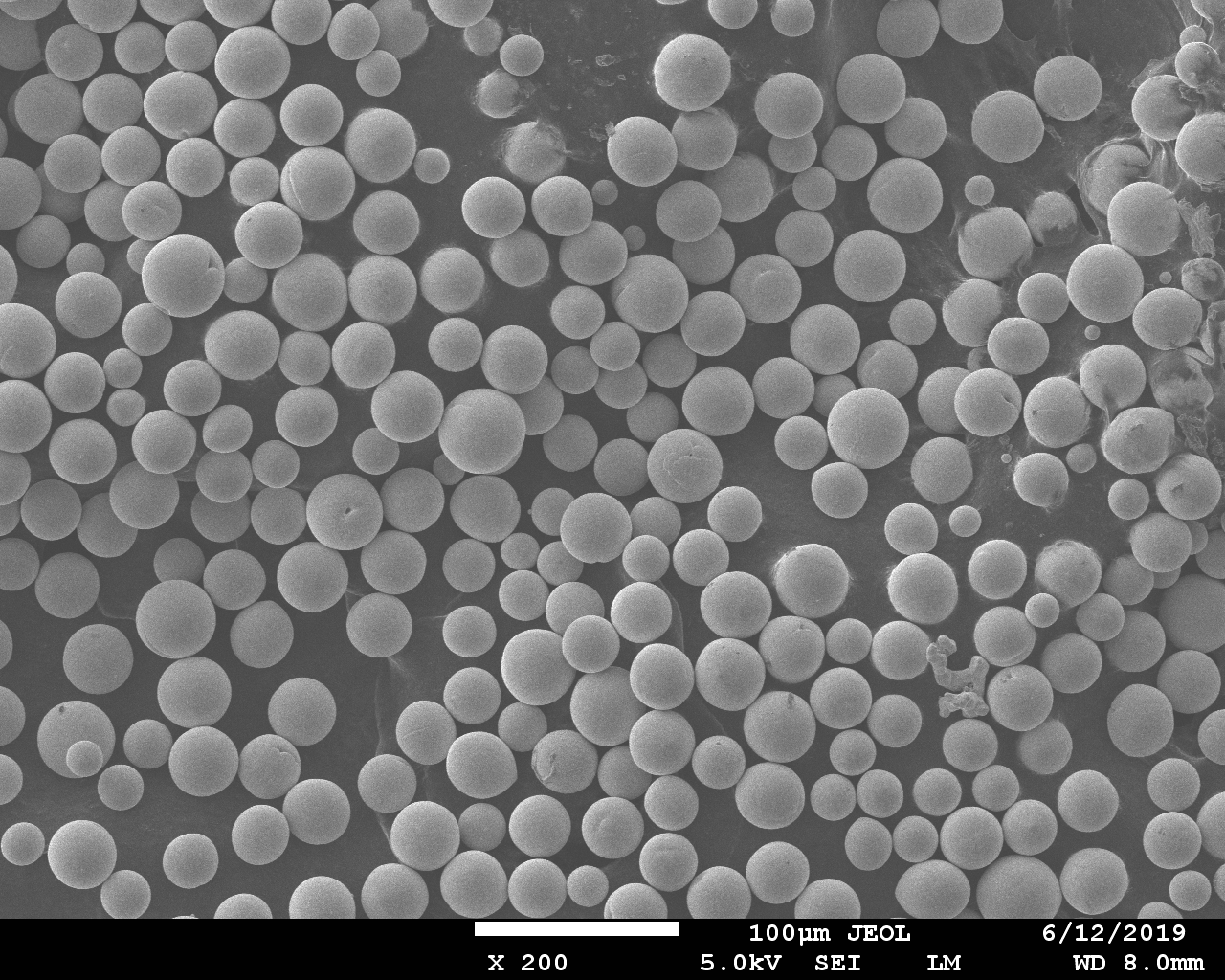

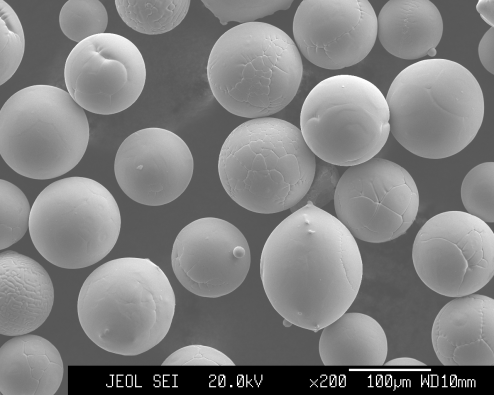

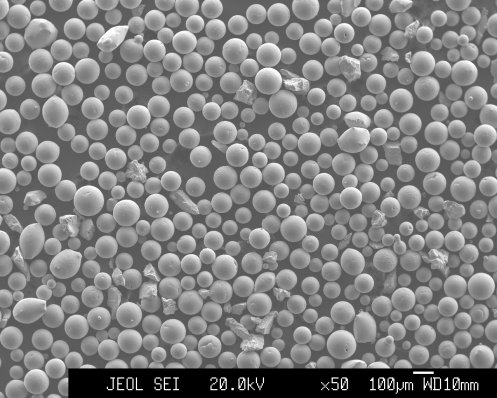

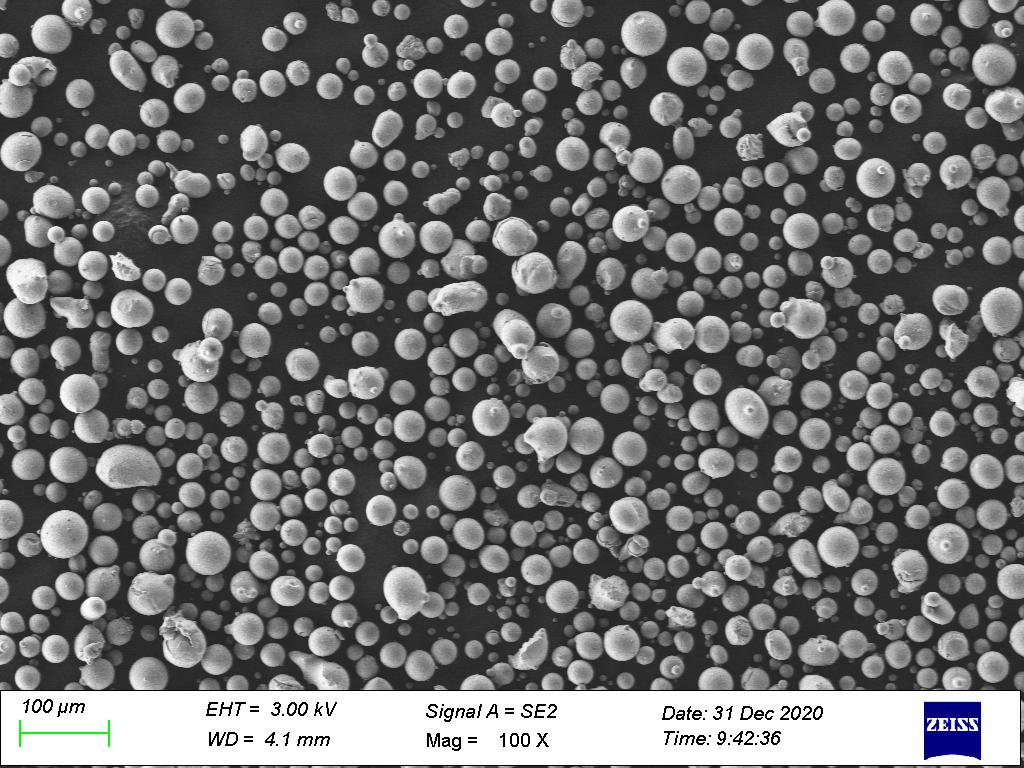

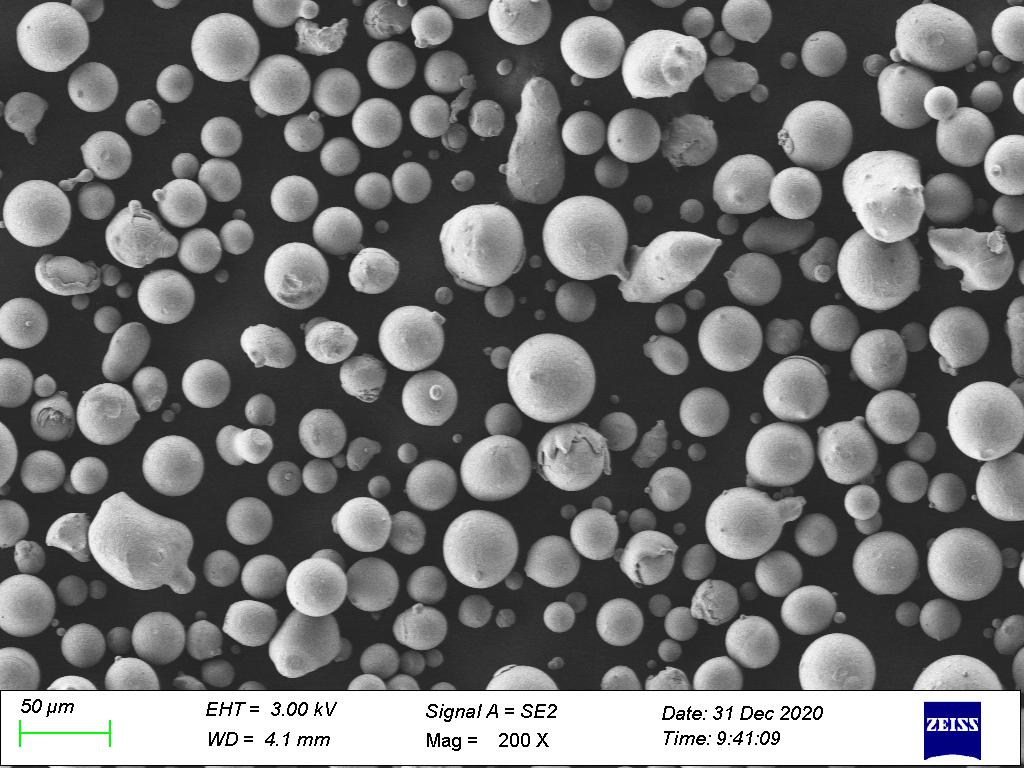

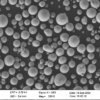

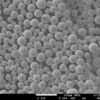

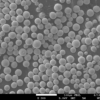

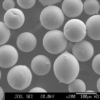

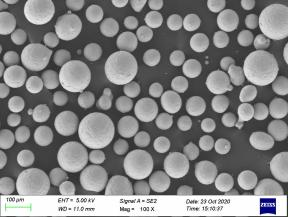

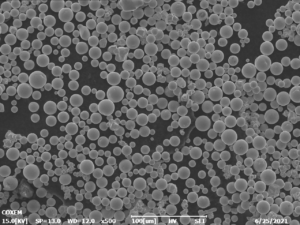

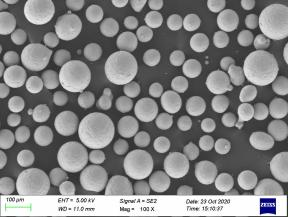

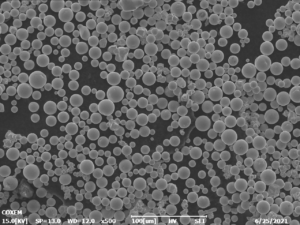

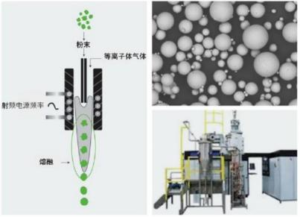

3.Pictures of Powder SEM morphology

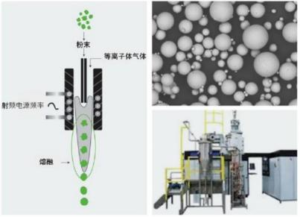

Pictures of Production and Test:

Pictures of Production and Test:

4.Application

4.Application

| Chemical Composition (wt.%) | ||||||||

| Element | Ni | C | S | P | Si | Co | Fe | O |

| Standard | ≥99.7 | / | / | / | / | / | / | / |

| Typical | 99.8 | 0.015 | 0.003 | 0.004 | 0.014 | 0.019 | 0.02 | 0.018 |

| Spherical nickel powder | Particle Size Distribution | Flow Rate (sec. for 50 g) | Apparent density (g/cm3) | Tap density (g/cm3) | ||

| Standard | 15~45μm, 45~106μm | ≤25 | ≥4.0 | ≥4.0 | ||

Pictures of Production and Test:

Pictures of Production and Test:

4.Application

4.Application

- Metal 3D printing and Laser cladding: Spherical nickel powder has good fluidity and melting properties, suitable for 3D printing and laser cladding technology, and can accurately construct complex structured parts.

- Surface spraying: Spherical nickel powder has good fluidity and is suitable for surface spraying, providing excellent coating quality and corrosion resistance.

- Diamond tools: In diamond tool manufacturing, spherical nickel powder is used as a binder to improve the hardness and wear resistance of the tool.

- Battery positive electrode material: Spherical nickel powder is used as a positive electrode material for batteries, which can improve the performance and lifespan of the battery.

- Conductive coating: Spherical nickel powder is also used to prepare conductive coatings, which are widely used in fields such as electronics and aviation, providing excellent conductivity.