Nickel based alloy powder for spraying

Product Character:

Nickel based alloy powder is widely used in various industrial fields due to its excellent comprehensive properties, such as corrosion resistance, oxidation resistance, heat resistance, low stress abrasive wear resistance, and good impact toughness.

| Brand Name | Jinchun |

| Origin | China |

| Product name | Nickel based alloy powder |

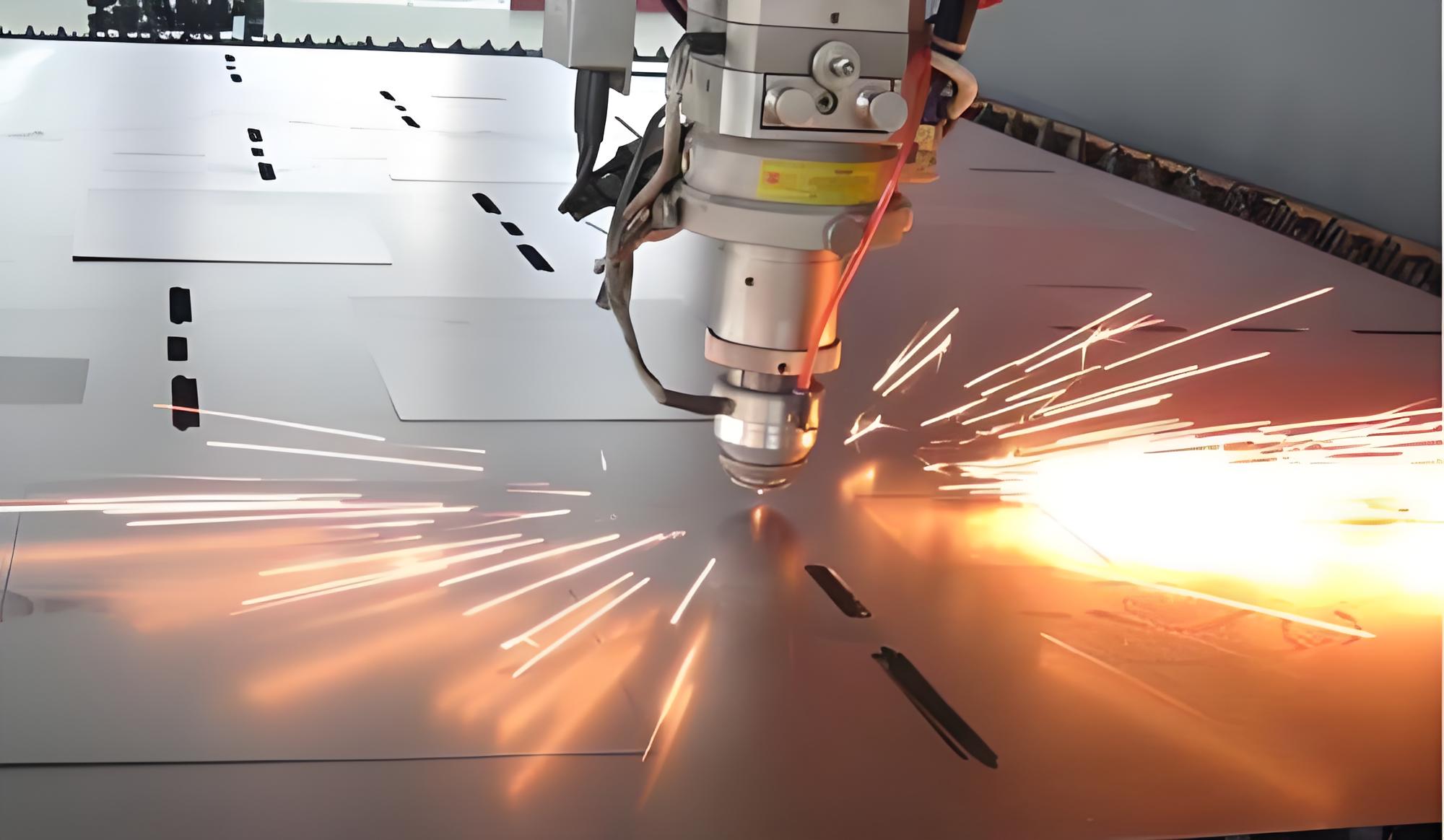

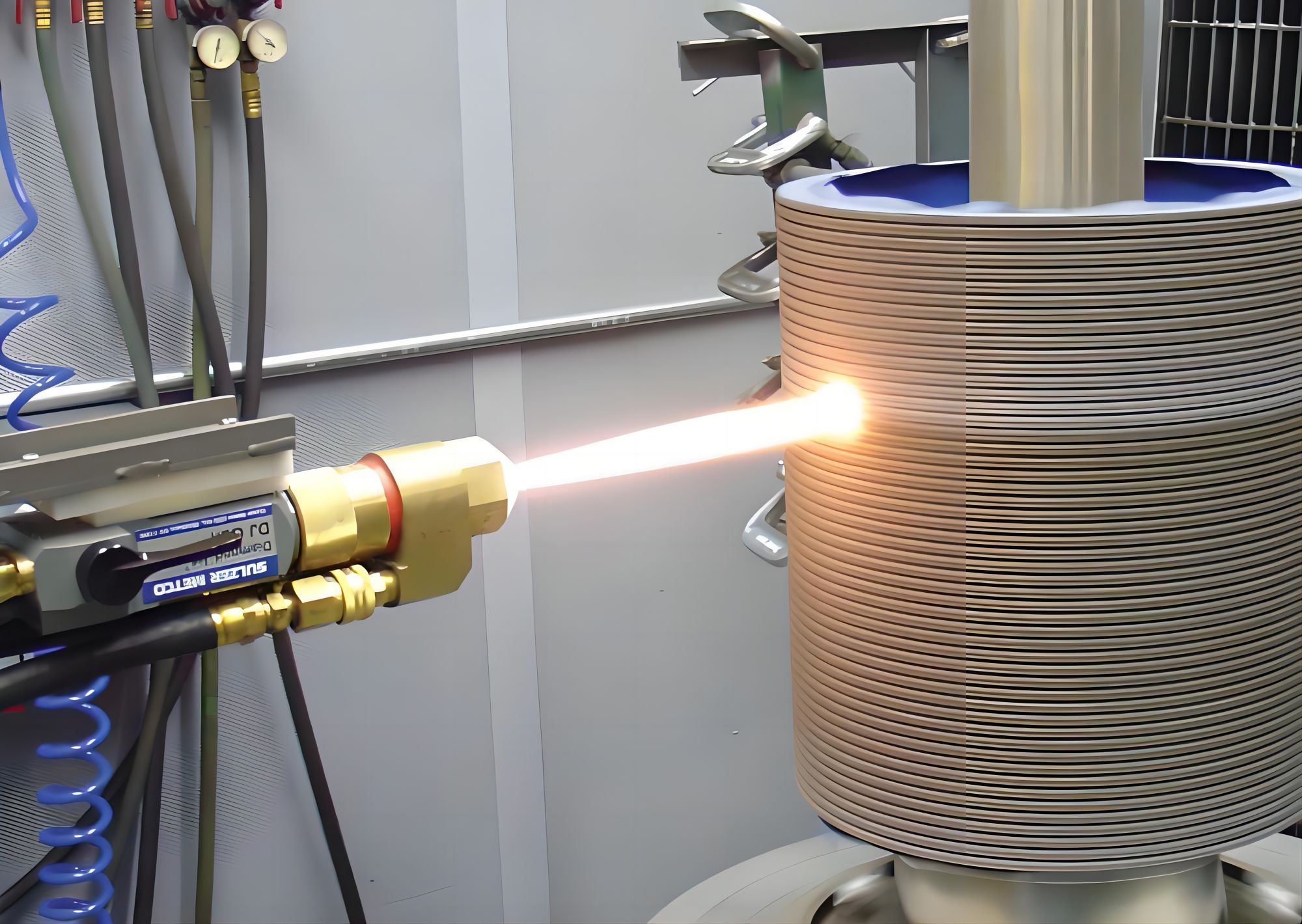

| Application | Spraying, Laser, etc. |

| Shape | Powder |

| Color | Metal gray |

| Size | 150-300 mesh, etc. |

| Standard | GB/T 19001-2016/ISO9001: 2015 |

| Purity | Ni: Bal |

| Material | Nickel plate, and other metals. |

| Packing | Steel drums |

PRODUCT DETAIL

PRODUCT DETAIL

Product Character

Nickel based alloy powder is widely used in various industrial fields due to its excellent comprehensive properties, such as corrosion resistance, oxidation resistance, heat resistance, low stress abrasive wear resistance, and good impact toughness.

2.Specification

Nickel based alloy powder for spraying

3.Pictures of Raw Materials and Production

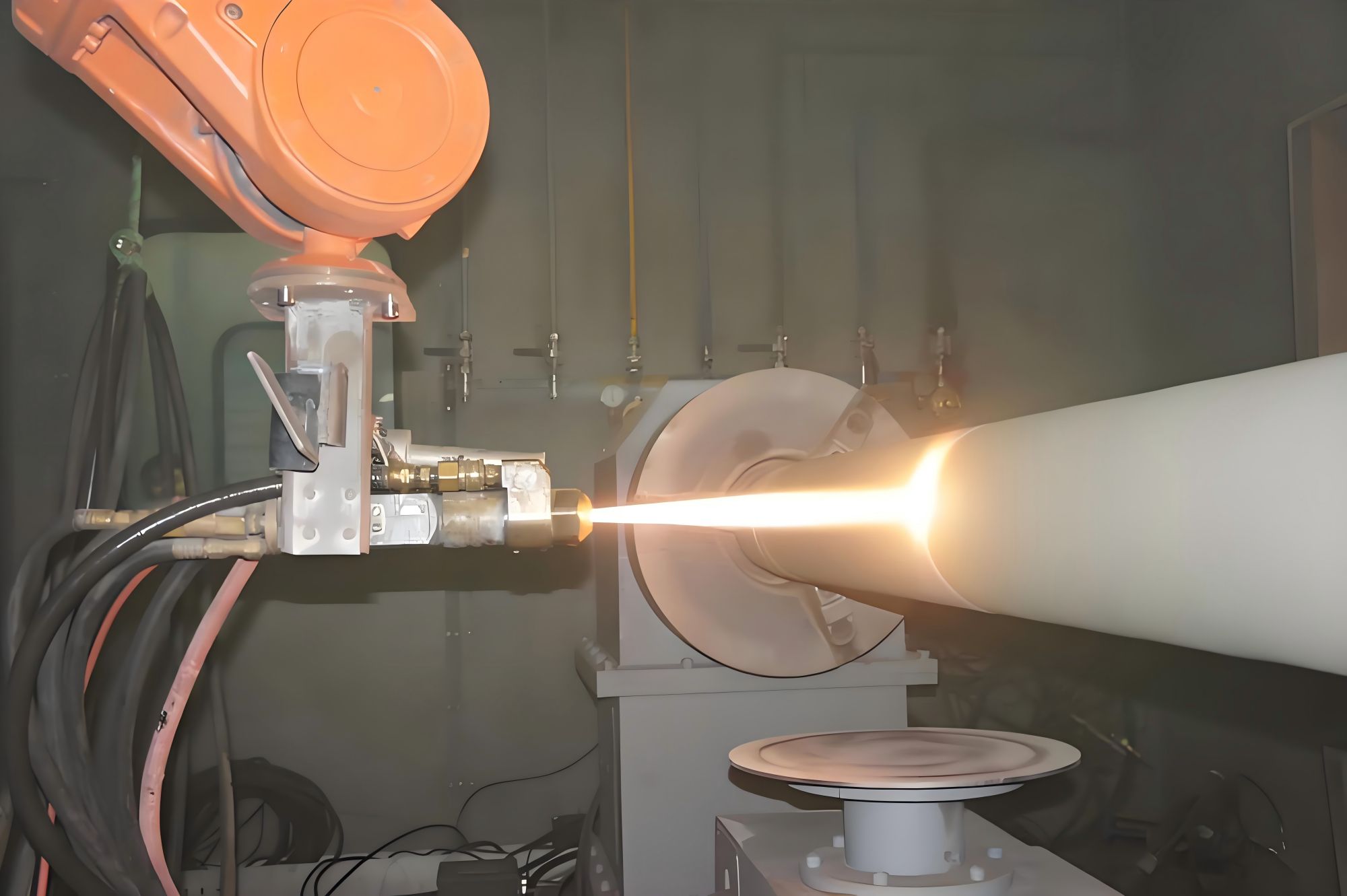

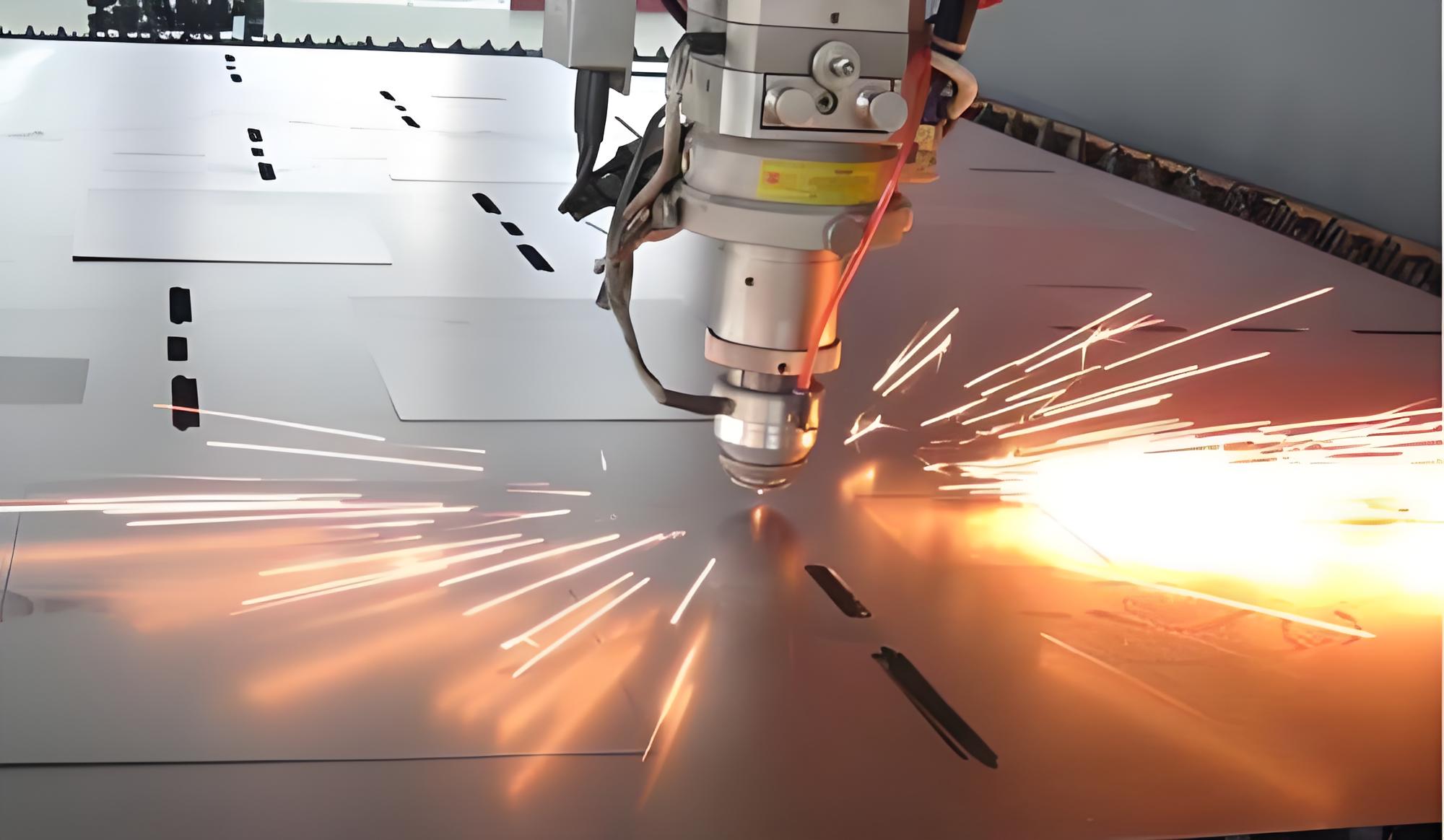

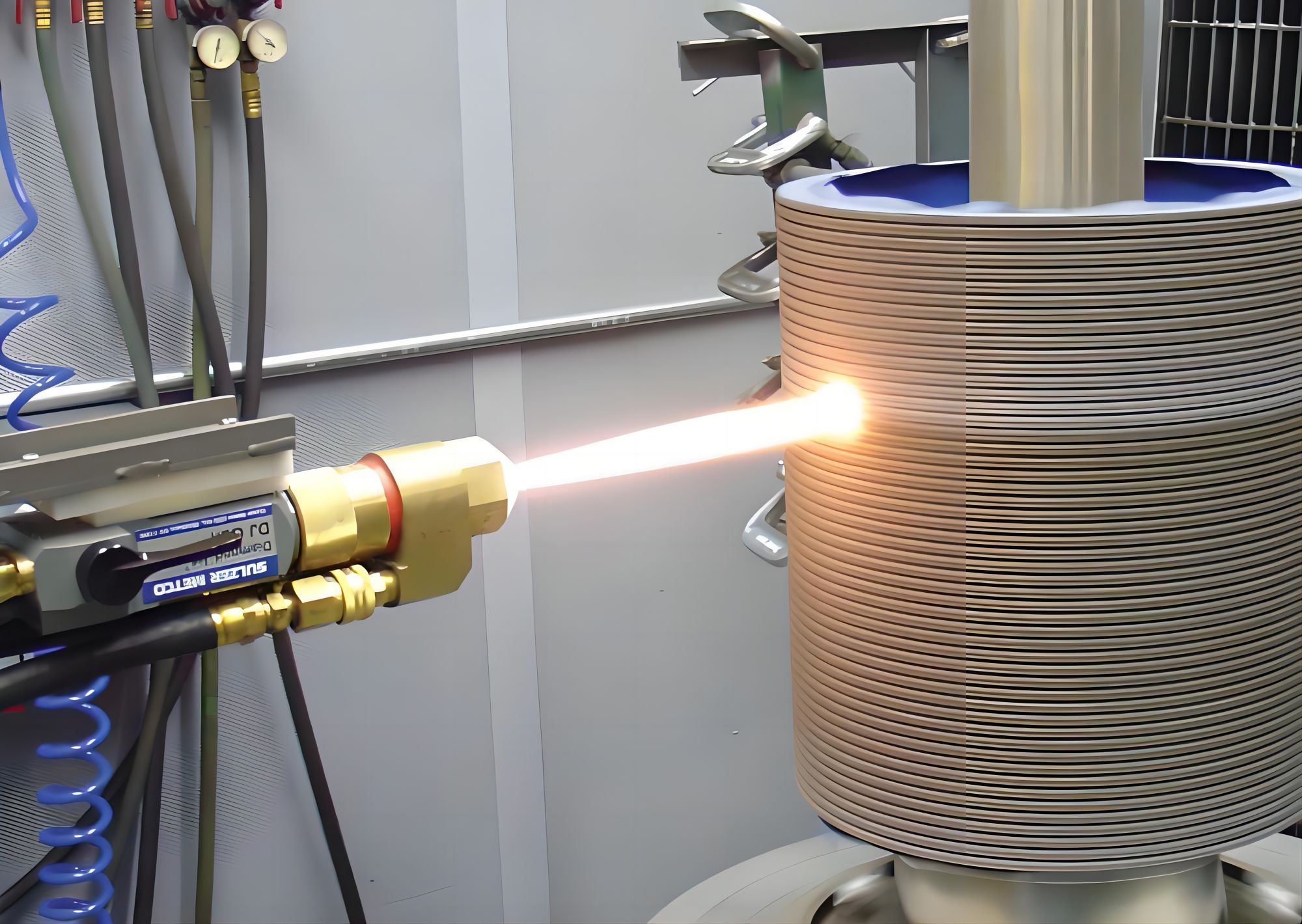

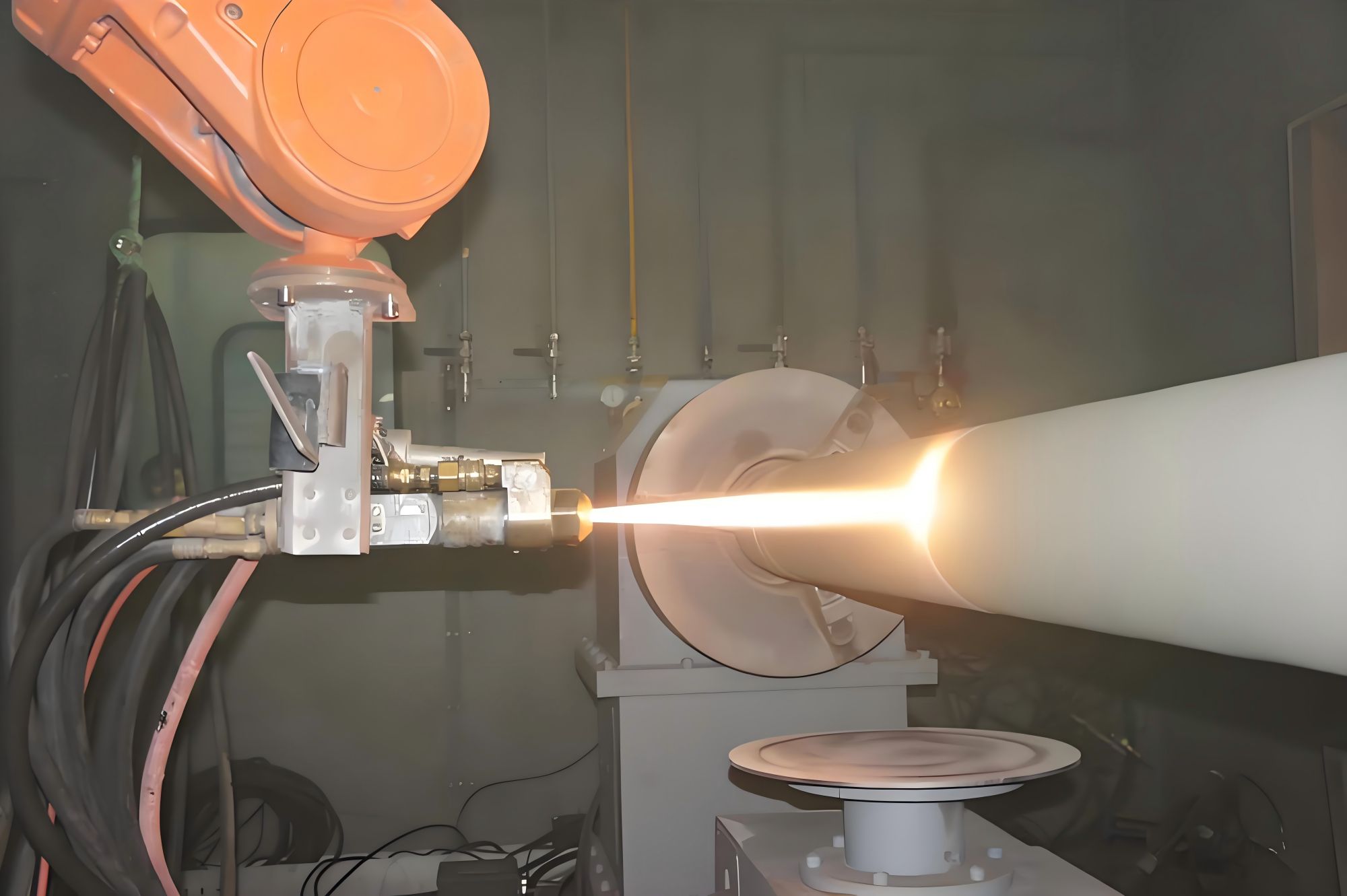

Pictures of Production:

4.Application

4.Application

| No. | Type | Hardness | Chemical Components (%) | Applications | Spraying Method |

| 1 | T-Ni15 | 15 | C:0.1, Si: 2.0, B: 1.0, Cr: 0.5, Fe:<5.0. Ni: Bal. | Specially developed for repairing castings: For example: molds, cylinders, guide rails, etc | Flame, Plasma spraying; Laser |

| 2 | T-Ni17 | 17 | C:0.1, Si: 3.0, B: 1.0, Cr: 1.0, Fe:<15.0. Ni: Bal. | ||

| 3 | T-Ni20A | 20 | C:0.1, Si: 3.0, B: 1.0, Cr: 1.0, Fe:<6.0. Ni: Bal. | ||

| 4 | T-Ni20B | 20 | C:0.1, Si: 3.0, B: 1.0, Cr: 5.0, Fe:<15.0. Ni: Bal. | ||

| 5 | T-Ni22A | 22 | C:0.1, Si: 3.0, B: 1.0, Cr: 1.0, Fe:<0.1. Ni: Bal. | Low melting point, can spray for large surface repair | |

| 6 | T-Ni25A | 25 | C:0.1, Si: 3.0, B: 1.0, Cr: 1.0, Fe:<6.0. Ni: Bal. | Repair of cast iron, steel components, and glass molds | |

| 7 | T-Ni25B | 25 | C:0.3, Si: 3.0, B: 1.0, Cr: 5.0, Fe:<15.0. Ni: Bal. | ||

| 8 | T-Ni35A | 35 | C:0.3, Si: 3.0, B:2.2, Cr:10.0, Fe:<5.0. Ni: Bal. | Shaft, punch, valve, gear surface repair | Flame, Plasma spraying |

| 9 | T-Ni35i | 35 | C:0.3, Si: 3.0, B:2.2, Cr:10.0, Fe:<15.0. Ni: Bal. | ||

| 10 | T-Ni40A | 40 | C:0.3, Si: 3.0, B:2.5, Cr:10.0, Fe:<5.0. Ni: Bal. | Punch, valve, valve, gear surface repair | |

| 11 | T-Ni45A | 45 | C:0.3, Si: 3.0, B:2.2, Cr:10.0, Fe:<5.0. Ni: Bal. | Repair of sealing surfaces, valves, valves, pistons, rotors, etc | |

| 12 | T-Ni45 | 45 | C:0.4, Si: 3.0, B:2.8, Cr:12.0, Fe:<15.0. Ni: Bal. | ||

| 13 | T-Ni50A | 50 | C:0.5, Si: 3.0, B:3.8, Cr:12.0, Fe:<5.0. Ni: Bal. | Repair of valves, sealing surfaces, oil plungers, shafts, etc. | |

| 14 | T-Ni50 | 50 | C:0.5, Si: 3.0, B:3.8, Cr:12.0, Fe:<15.0. Ni: Bal. | ||

| 15 | T-Ni55A | 55 | C:0.8, Si: 4.0, B:3.0, Cr:14.0, Fe:<5.0. Ni: Bal. | ||

| 16 | T-Ni55 | 55 | C:0.8, Si: 4.0, B:3.0, Cr:14.0, Fe:<15.0. Ni: Bal. | ||

| 17 | T-Ni60A | 60 | C:0.9, Si: 4.0, B:3.2, Cr:16.0, Fe:<5.0. Ni: Bal. | Repair of wire drawing drum, cam, plunger, conveyor roller, etc | |

| 18 | T-Ni60B | 60 | C:0.9, Si: 4.0, B:3.0, Cr:16.0, Fe:<5.0. Ni: Bal. | ||

| 19 | T-Ni60CuMo | 60 | C:0.9, Si: 4.0, B:4.0, Cr:16.0,Cu:3.2, Mo:3.0, Fe:<5.0. Ni: Bal. | Repair valves, impellers, plungers, valves, etc | |

| 20 | T-Ni60CuMoW | 60 | C:0.9, Si: 4.0, B:4.0, Cr:16.0,Cu:3.2, Mo:3.0,W: 3.0, Fe:<5.0. Ni: Bal. | ||

| 21 | T-Ni65 | 65 | C:1.1, Si: 4.0, B:4.0, Cr:18, Fe:<5.0. Ni: Bal. | Repair wire drawing drum, cam, etc | |

| 22 | T-Ni150 | 150 | C:0.3, Si: 2.0, B: 1.2, Cr: 12, Fe:<5.0. Ni: Bal. | Shaft system and pump sleeve repair | HVOF, Flame, Plasma spraying |

| 23 | T-Ni250 | 250 | C:0.4, Si: 2.0, B: 1.3, Cr: 13,Al: 0.3, Fe:<5.0. Ni: Bal. | Repair of the roller, plunger,machine axis,crankshaft,roll | |

| 24 | T-Ni280 | 280 | C:0.4, Si: 2.0, B: 1.7, Cr: 12,Al: 0.3, Fe:<5.0. Ni: Bal. | ||

| 25 | T-Ni320 | 320 | C:0.6, Si: 3.0, B: 2.0, Cr: 16,Al: 0.3, Fe:<7.0. Ni: Bal. | ||

| 26 | T-Ni1450 | 450 | C:0.8, Si: 4.0, B: 2.5, Cr: 18,Al: 0.3, Fe:<7.0. Ni: Bal. | ||

| 27 | T-NiCrMoSi | 230 | Si:4.0, Cr: 22, Fe: 4.0, Ni: Bal. | Anti-wear magnetic alloy,Low magnetic loss, used for protection of magnetic probes and other heads | HVOF, Flame, Plasma spraying; Laser |

4.Application

4.Application

HVOF, Flame, Plasma spraying; Laser

_6258副本-2.jpg)