Spherical Metal Powders GH4099 Nickel based High-temperature alloy powder

Product Character:

GH4099 is a typical aging strengthened nickel based high-temperature alloy, which is comprehensively strengthened with elements such as Co, W, Al, Ti, etc., giving the alloy high thermal strength. It can be used for a long time below 900 ℃, and the highest working temperature can reach 1000 ℃. Due to its stable microstructure and satisfactory cold and hot forming and welding process performance, GH4099 high-temperature alloy is very suitable for manufacturing high-temperature plate load-bearing welding structures such as aviation engine combustion chambers and afterburner chambers.

| Brand Name | Jinchun |

| Origin | China |

| Product name | GH4099 powder |

| Application | High-temperature plate load-bearing welding structures, etc. |

| Shape | Powder |

| Color | Metal gray |

| Size | 15~53μm |

| Standard | GB/T 19001-2016/ISO9001: 2015 |

| Purity | Ni: Bal. , Cr:17-20%, Mo:3.5-4.5%, Co: 5.0-8.0%, W:5.0-7.0%, Al: 1.7-2.4%, Ti: 1-1.5%. |

| Material | Ni, Cr, Mo, W, Ti, Al, Co |

| Packing | Vacuum packing |

PRODUCT DETAIL

PRODUCT DETAIL

Product Character

GH4099 is a typical aging strengthened nickel based high-temperature alloy, which is comprehensively strengthened with elements such as Co, W, Al, Ti, etc., giving the alloy high thermal strength. It can be used for a long time below 900 ℃, and the highest working temperature can reach 1000 ℃. Due to its stable microstructure and satisfactory cold and hot forming and welding process performance, GH4099 high-temperature alloy is very suitable for manufacturing high-temperature plate load-bearing welding structures such as aviation engine combustion chambers and afterburner chambers.

2.Specification

GH4099 powder

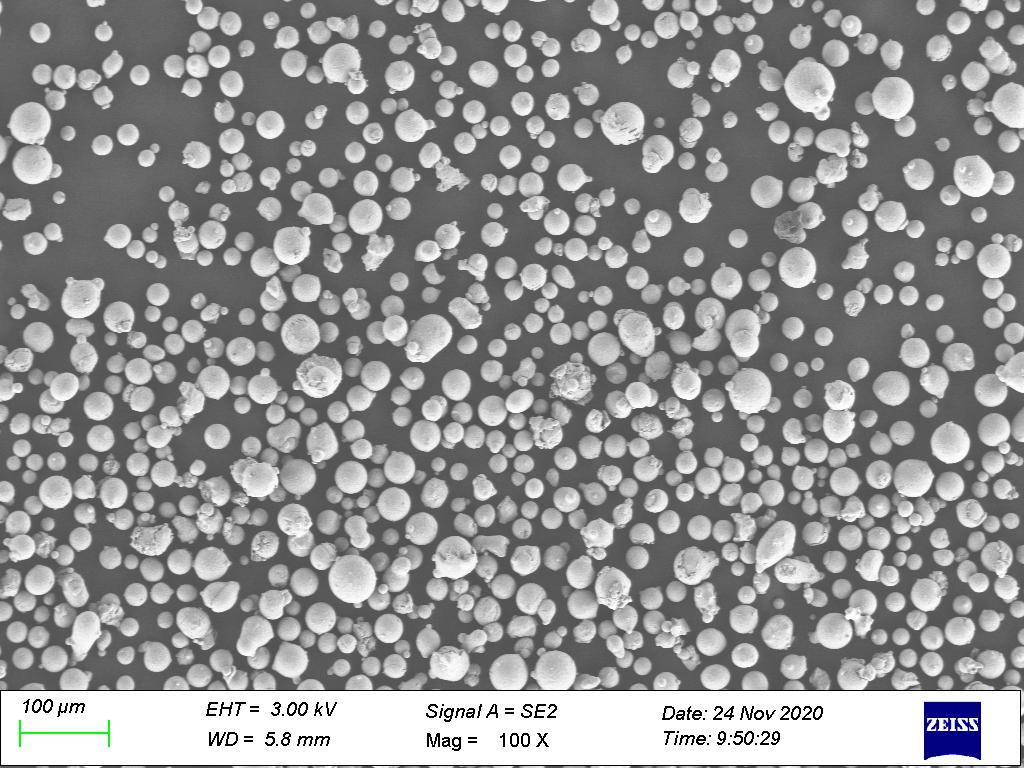

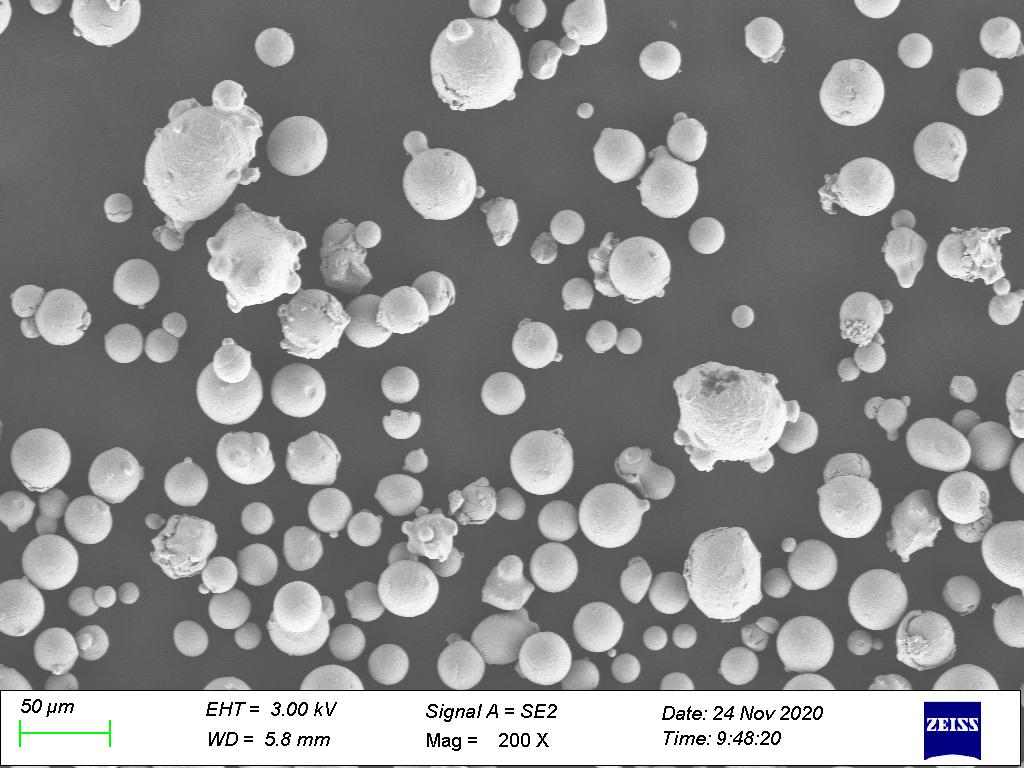

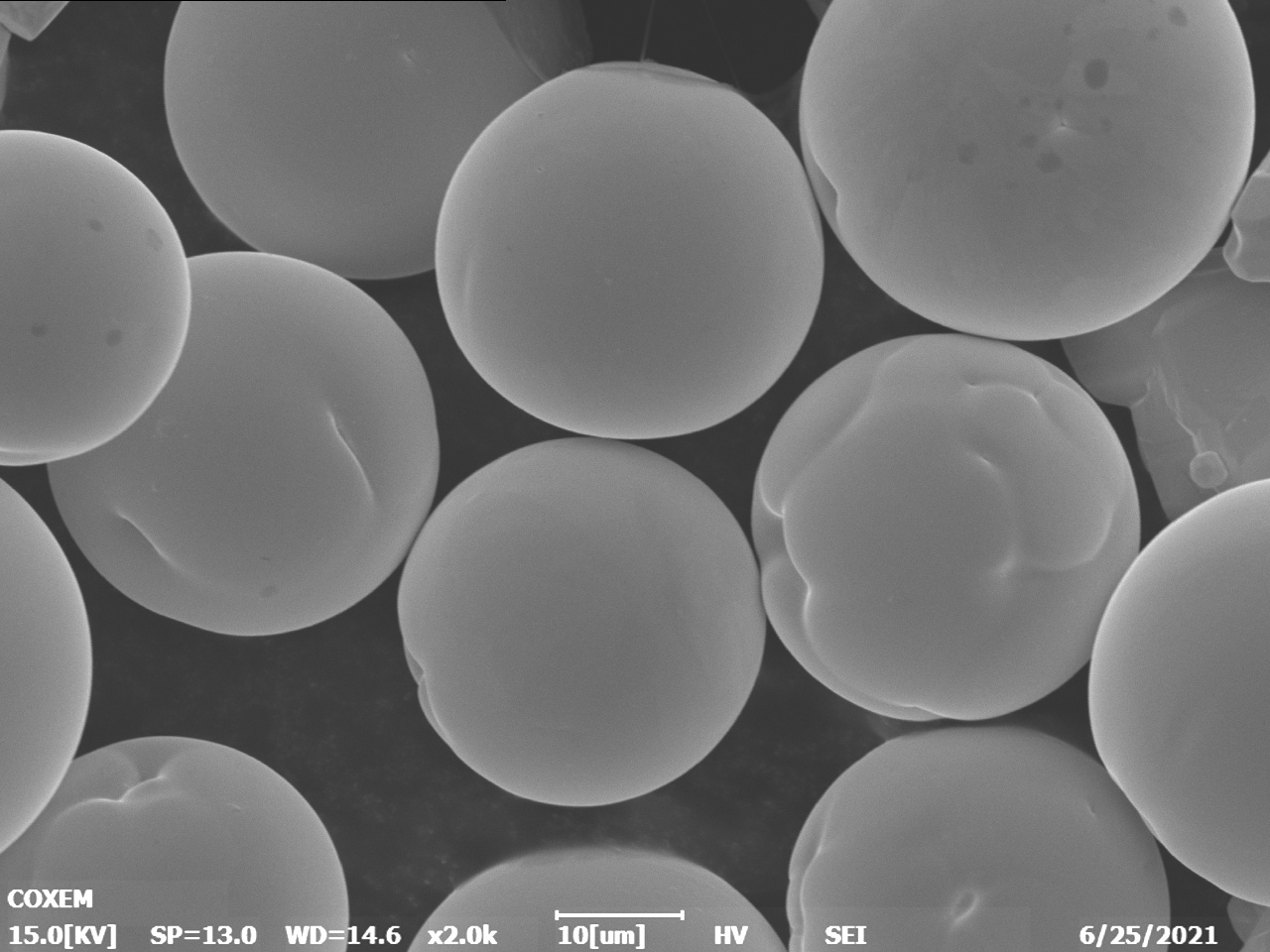

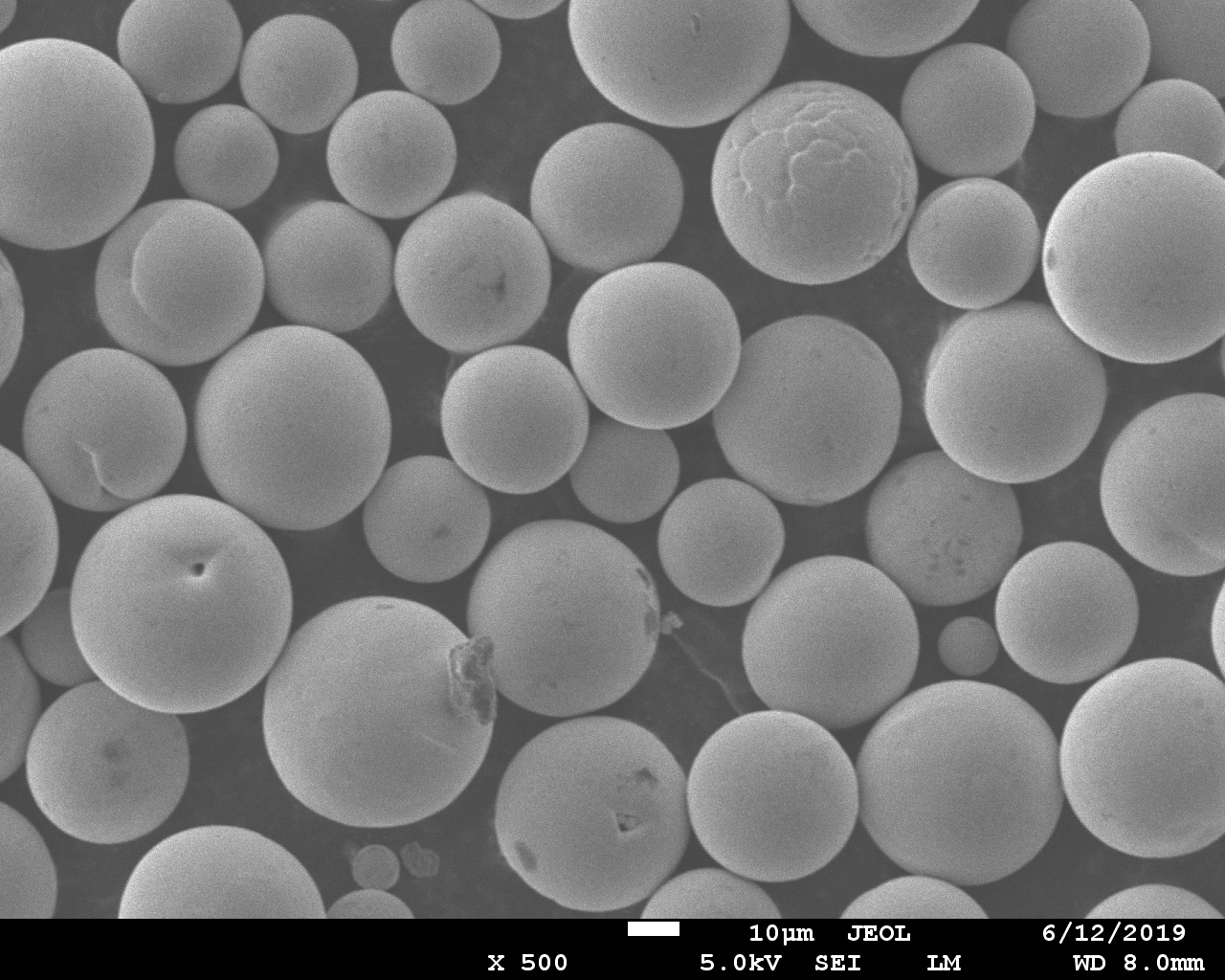

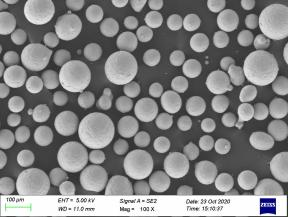

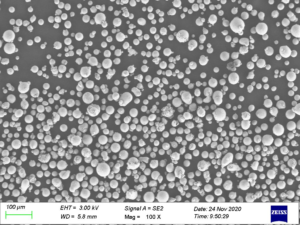

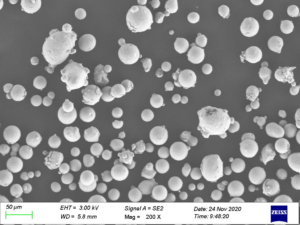

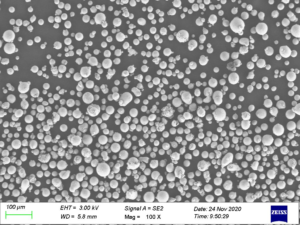

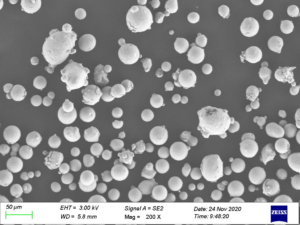

3.Pictures of Powder SEM morphology

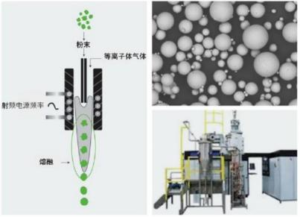

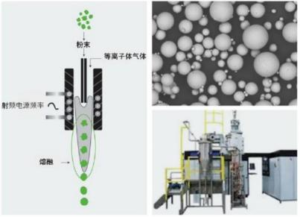

Pictures of Production and Test:

Pictures of Production and Test:

4.Application

4.Application

| Chemical Composition (wt.%) | |||||||||

| Element | C | Cr | Ni | Co | W | Mo | Ti | Fe | B |

| Standard | ≤0.08 | 17.0~20.0 | Bal. | 5.0~8.0 | 5.0~7.0 | 3.5~4.5 | 1.0~1.5 | ≤2.0 | ≤0.005 |

| typical | 0.031 | 18.08 | Bal. | 6.38 | 5.99 | 4.07 | 1.21 | 0.084 | 0.004 |

| Element | Mn | P | S | Al | Mg | Si | Ce | O | N |

| Standard | ≤0.40 | ≤0.015 | ≤0.015 | 1.7~2.4 | ≤0.01 | ≤0.50 | ≤0.02 | ≤0.030 | ≤0.030 |

| typical | 0.03 | 0.006 | 0.00063 | 2.01 | 0.001 | 0.1 | 0.006 | 0.0072 | 0.017 |

| GH4099 | 15~53μm Particle Size Distribution | Flow Rate (sec. for 50 g) | Apparent density (g/cm3) | Tap density (g/cm3) | ||

| D10 | D50 | D90 | ||||

| Standard | 15~25 | 30~40 | 50~60 | ≤25 | ≥4.2 | ≥4.9 |

| typical | 22.2μm | 35.5μm | 54.3μm | 16.2 | 4.58 | 5.26 |

Pictures of Production and Test:

Pictures of Production and Test:

4.Application

4.Application

- GH4099 high-temperature alloy is very suitable for manufacturing high-temperature plate load-bearing welding structures such as aviation engine combustion chambers and afterburner chambers.